IEC60061-3 G5 Go No Go Ball Gauge

- Min. Order:

- 20 Set/Sets

- Min. Order:

- 20 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 Sets /Week |

| Supply Ability: | 100 Sets /Week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR,DDU,DDP,Express Delivery |

| Certificate: | ISO9001 Quality Control System |

| HS Code: | 9031809090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai,Shenzhen |

Non-Standard Processing Custom GO NOGO Ball Gauge

General regulation, that is, the lower limit of aperture allowed deviation, if not through, it shows that the aperture is small, unqualified, check, that is, the upper limit of aperture allowed deviation, if the check can pass, that the aperture is large, also unqualified, in short, the general regulation is qualified.

When machining a large number of inner circular parts, a gauge is used for convenience and quick information, namely the pass gauge and the stop gauge. The pass gauge and the stop gauge are made on a cylinder body. The long end of the pass gauge is good enough to pass through the hole, and the short end is good enough to pass through the hole. If the stop gauge can smoothly screw into the measured thread hole 2.5 laps or more, it is unqualified and otherwise qualified. And at this time the unqualified thread hole should be scrapped, can not be reworked.

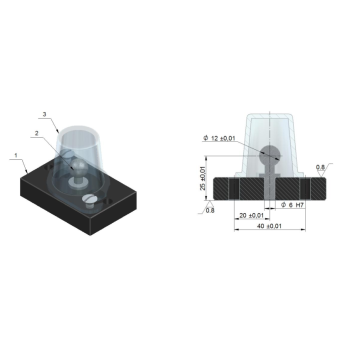

Technical Request:

1. No chamfering C0.5, deburring

2. No tolernace of +/-0.3mm

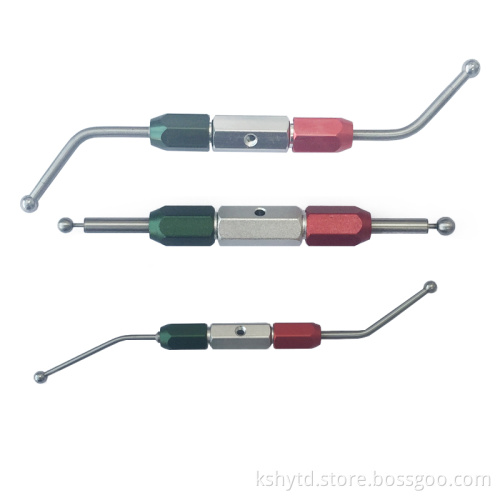

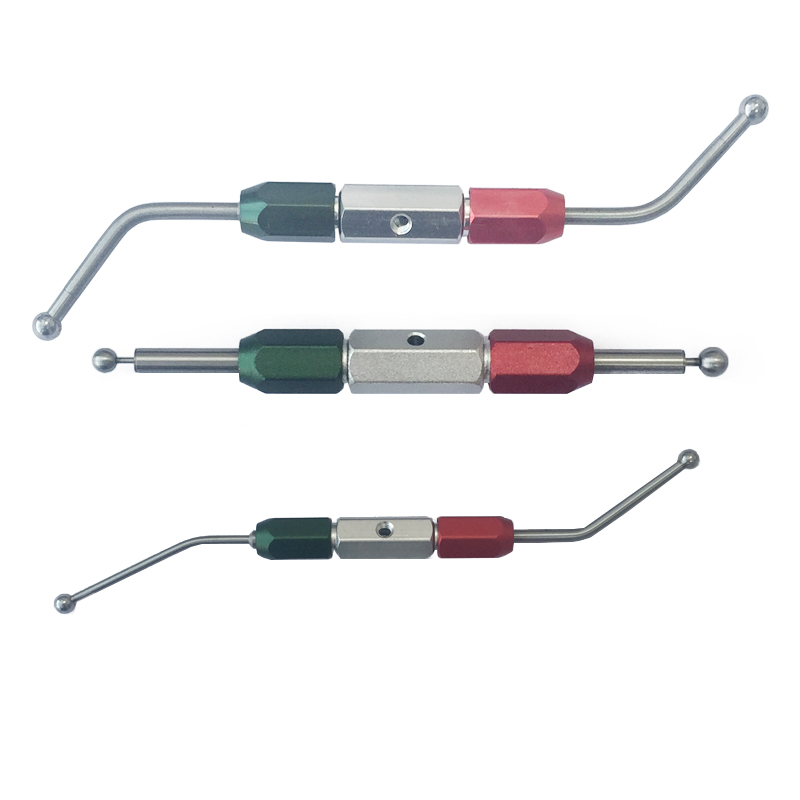

Raw material: Aluminum Alloy+Copper Chuck

Surface Treatment: Anodizing

Color: Red for Nogo part, Green for Go part

Copper Chuck and Handle are assembled

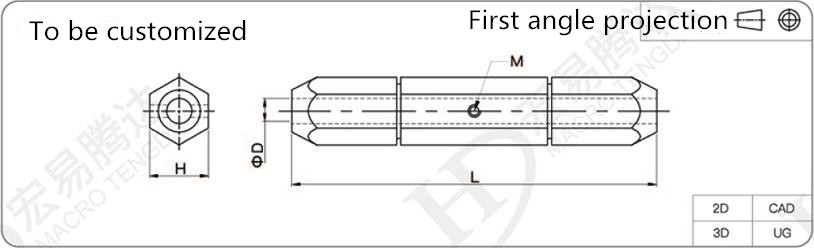

Standard Double Ended Gauge Handles

| H | D | L | M |

| 09 | Φ4 | 55 | M3 |

| 10 | Φ4 | 57 | M3 |

| 12 | Φ6/Φ4 | 80 | M3 |

| 14 | Φ6/Φ4 | 87 | M3 |

| 18 | Φ9 | 95 | M4 |

| 22 | Φ13 | 110 |

M4 |

Why choose us?

1.Our Inventory of Checking Components of automotive

We have thousands of checking fixtures components for automotive gauge in our warehouse, such as mechanism, measuring and adjustable holder, checking pins, plates and plastic cover, Go Nogo pins, inch tooling balls etc. We can provide fast delivery, improve efficiency, shorten production time, you could get it fastly as your local market under in the case of fierce competition of automobile fixture.

Standard Components Lead Time: 3-5 days.

Custom Components Lead Time: 7 Working day.

2.Our Design and 3D datas

Our design team can provide CAD and 3D datas service, we are glad to share 3D datas with you and help you to build 3d Datas, thus use our standard components, save your energy, shorten your design and production time.

3.Sample Service and Mass Production

MOQ: 1PCS, we can provide sample service to help you to test products' quality for first cooperation.

Relevant Jig Checking Components, such Checking Pins, Plastic Cover, Aluminum Alloy Cover, Spring, Metal Parts, Adjustable Holder etc.

4.Our Workshop

Currently We have 3 CNC high speed machining machines, 6 Punch Machines, 8 Grinding Machines, CMM Inspection, Projector, Digital Caliper etc. We have Production department, Quality Control department, Packaging Department, Sales and Design department, we have formed a standard work flow.

Related Keywords