GO NOGO Gauge Custom

- Min. Order:

- 10 Set/Sets

- Min. Order:

- 10 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 Sets /Week |

| Supply Ability: | 1000 Sets /Week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR,DDU,DDP,Express Delivery |

| Certificate: | ISO9001 Quality Control System |

| HS Code: | 9031809090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai,Shenzhen |

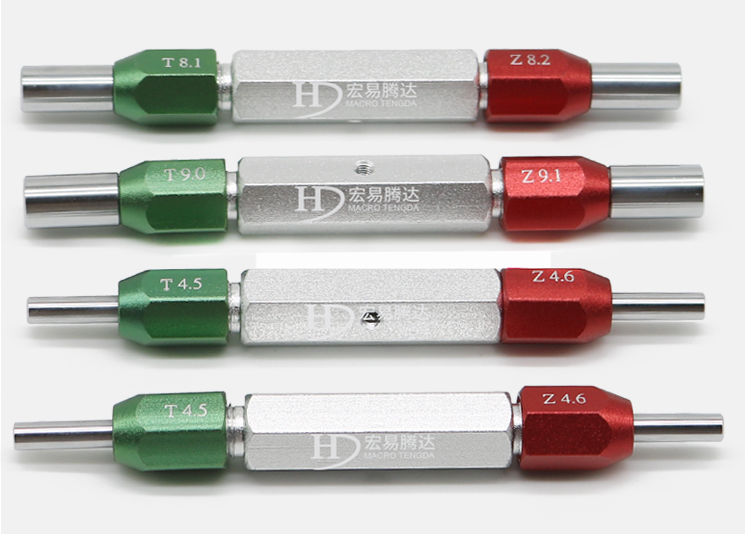

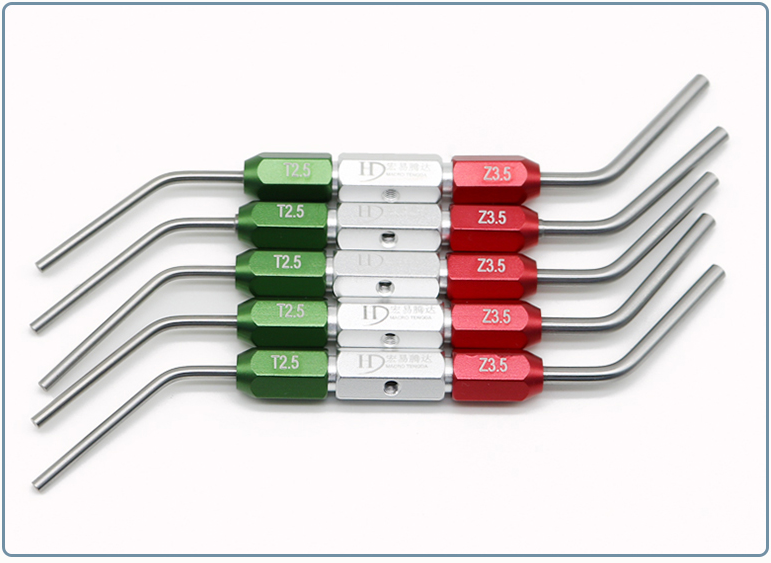

GO NOGO Pin Gages For Automotive Jig Components

A go no go gauge is typically used in manufacturing settings to quickly check to see if an item is within the allowed tolerances. While it does not return an actual measurement it does allow an operator to know whether something is acceptable or unacceptable. To utilize a go no go gauge the operator must test a piece at both ends. An acceptable piece should pass the “go” test and fail the “no go” test.

One form of go no go gauge, a snap gauge is built to offer this test by utilizing anvils at opposite ends of a “C” shaped frame. Some snap gauges offer anvils at multiple locations, allowing the operator to determine whether the artifact passes or fails both with one tool.

Go no go gauges, also come in both non-threaded smooth variety, such as a pin gauge, or threaded versions which check threaded connections. The benefit of go no go gauges is the ease of use – they require very little skill or interpretation to use correctly.

Cross Precision Measurement offers a variety of go no go gauges from the brands you know and trust such as Vermont Gage, Glastonbury Southern Gage, Mitutoyo, and Starrett. Contact our expert sales team to see which go/no-go gage is right for your application.

Technical Parameters

|

Product Name

|

Auto Fixture Checking Spherical GO NOGO Gage Set

|

|

Raw Material

|

S136 for GO NO-GO , Aluminum Alloy for Handle

|

|

Hot Treatment

|

HRC50-55°

|

|

Surface Treatment

|

Hard Plated for GO NOGO feelers, Sand Blasting for Aluminum Handle

|

We also can make custom in Sizes, metric sizes or inch sizes are accepted.

Product Details

Double Ended GO NOGO PIN Gauges Handles

Relevant other parts: Threaded Checking Pins, Single End Pins Handles, Lathe Steel Parts

Tooling Balls Checking Fixtures Components for Car, these parts can be customised.

Why choose us?

1.Our Inventory of Checking Components of automotive

We have thousands of checking fixtures components for automotive gauge in our warehouse, such as mechanism, measuring and adjustable holder, checking pins, plates and plastic cover, Go Nogo pins, inch tooling balls etc. We can provide fast delivery, improve efficiency, shorten production time, you could get it fastly as your local market under in the case of fierce competition of automobile fixture.

Standard Components Lead Time: 3-5 days.

Custom Components Lead Time: 7 Working day.

2.Our Design and 3D datas

Our design team can provide CAD and 3D datas service, we are glad to share 3D datas with you and help you to build 3d Datas, thus use our standard components, save your energy, shorten your design and production time.

3.Sample Service and Mass Production

MOQ: 1PCS, we can provide sample service to help you to test products' quality for first cooperation.

Relevant Jig Checking Components, such Checking Pins, Plastic Cover, Aluminum Alloy Cover, Spring, Metal Parts, Adjustable Holder etc.

4.Our Workshop

Currently We have 3 CNC high speed machining machines, 6 Punch Machines, 8 Grinding Machines, CMM Inspection, Projector, Digital Caliper etc. We have Production department, Quality Control department, Packaging Department, Sales and Design department, we have formed a standard work flow.

Related Keywords