Custom Production Tooling Balls

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai, Shenzhen, Weihai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 200 Piece/Week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR,DDU,DDP,Express Delivery |

| Certificate: | ISO9001 Quality Control System |

| HS Code: | 9031809090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai,Shenzhen,Weihai |

Tooling ball manufacturing is simple but demanding: correct materials, heat treating to the necessary specification and precision machining/grinding to achieve exact dimensions, concentricity and tight tolerances. These are the standards we adhere to in our tooling ball department.

Our promise:

We are proud to have achieved the precision, skill of workmanship and planning needed to manufacture tooling balls. Our dedication to these goals means we make promises we can keep: your tooling ball and construction ball orders correctly made, delivered on time, in full quantity and at reasonable pricing. We welcome your tooling ball inquiry and thank you for considering Anwright Corporation.

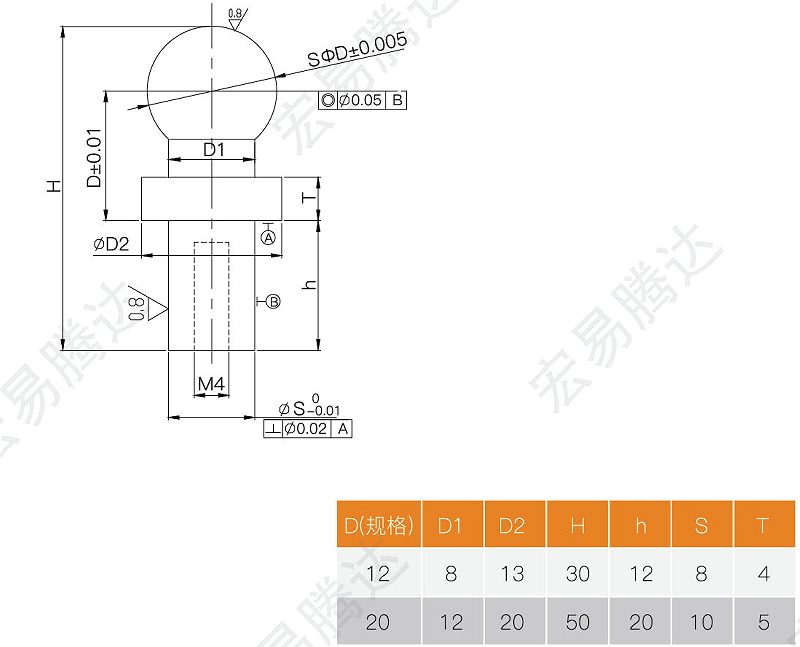

Standard Metric Tooling Balls Sizes, we also can make custom in sizes, such as inch tooling balls sizes custom ,non standard precision tooling balls sizes custom.

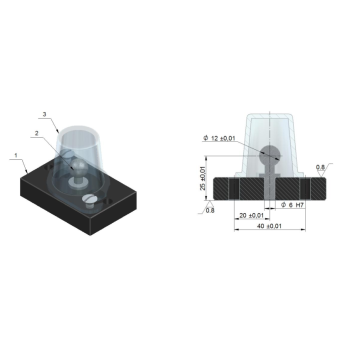

1. Installation of tool reference balls on mold die parts

To achieve the correct installation of the tool reference ball on the mold part, a groove of 45X20X1mm is first machined on the non-forming surface of the mold part. Machining a ¢6H7 positioning hole on one side of the groove, the hole depth is 2-3mm deeper than the tool reference ball positioning column. The coordinate value of the tool reference ball center relative to the design reference value of the mold part is engraved in the groove.

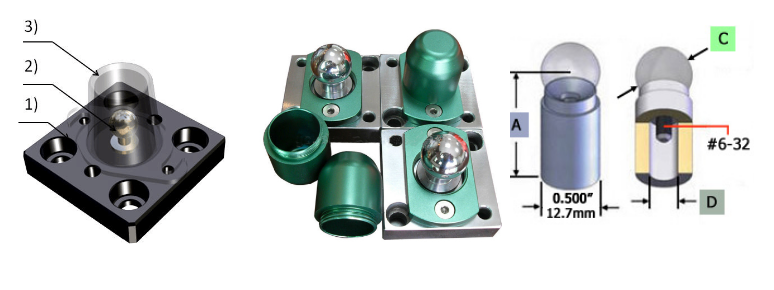

2. Application of tool reference ball in CNC machining

The picture below is a part of a car lamp mold. The part is a special-shaped part, there is no reference number around, only at the bottom of the part calibration position. The CNC processing order of the parts is: 1, first roughing the front forming surface and finishing tool of the installation groove and installation hole of the reference ball, 2, and then the reverse rough, finishing around the bevel, 3, finally finishing the front. When machining the front, the center of the tool reference ball is used as the machining reference of the part. After modifying the parts, use the tool reference ball as the reference. If you do not use a tool reference ball, like this part, it is difficult to find alignment.

3. Application of tool reference ball in EDM processing

The following figure is the core of a car lamp mold. The core needs EDM processing in many places. The part is an irregular part. In processing, we use the tool reference ball as the processing reference of the parts, which is easier to find and take the number. It is difficult to process EDM without using a tool reference ball.

Related Keywords