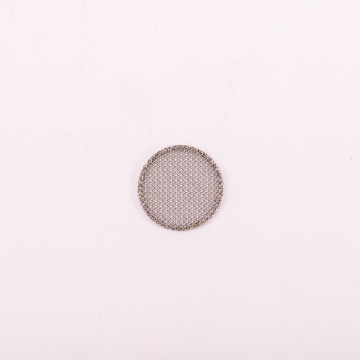

Customized wire mesh filter cap

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Tianjin

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000pcs |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Tianjin |

Product Description

Product Description

Filter Cap can be used in petroleum chemical industry, oil field pipeline filter, fuel refueling equipment filter, water treatment equipment filter, pharmaceutical and food processing field etc.Widely used in the hydraulic systems,water treatment,food and other industrial fields.1.Filter Cap is made of single layer or multi-layer metal mesh;The metal mesh layer and mesh count are decided by different conditions of use and purpose;With high concentricity rate, big pressure resistant;It is durable and strong that Stainless steel material makes;The screen more effective for filtration or extrusion;No burr,no move wire,long service life;It can be cleaned repeatedly and economically.

We are a manufacturer of wire mesh products, with over twenty years of experience in the wire mesh manufacturing industry. We possess strong technical support and after-sales problem-solving capabilities.In addition to filter caps, we also offer large and small filter plates, stainless steel mesh frames and baskets, and bathroom products, which are widely used in various fields such as daily life, industry, medical care, and experiments. Providing high-quality products for all kinds of customers has always been our pursuit. We constantly improve our manufacturing capabilities through strict management and technological breakthroughs, and with a proactive attitude, we meet the increasingly fierce market demands.

llation Steps:Clean the interior of the filter to ensure there are no residual impurities. Fix the filter caps on the perforated plate at the designed intervals and check the sealing. Slowly fill the filter material (such as quartz sand, activated carbon), avoiding impact damage to the filter caps.Maintenance Suggestions

- Regular backwashing is recommended to prevent clogging (start when the pressure difference exceeds 0.1 MPa).

- Drain the equipment when it is shut down to avoid cracking due to freezing or corrosion.

- Inspect the filter cap gaps for deformation or blockage every two years.

Quality Certification and Customization Services

- Certification Standards**: Compliant with ISO 9001, drinking water safety (NSF/ANSI 61), and other certifications.

- Customization: Supports non-standard sizes, special gap designs, material upgrades (such as titanium alloy), and other services.

Frequently Asked Questions

Q1: How to deal with clogged filter caps?

A1: Fouling can be removed by backwashing or soaking in diluted acid solution. Severe blockage requires replacement of the filter cap.

Q2: Can it be used in high-temperature steam environments?

The stainless steel filter cap can withstand temperatures below 150℃. For higher temperatures, heat-resistant alloy materials need to be customized.

Contact Us

For detailed technical parameters, quotations or samples, please contact our customer service. We will provide professional solutions based on your working conditions.

Through scientific selection and standardized application, filter caps can significantly enhance the stability and efficiency of filtration systems and are indispensable key components in industrial processes.

Related Keywords

Related Keywords