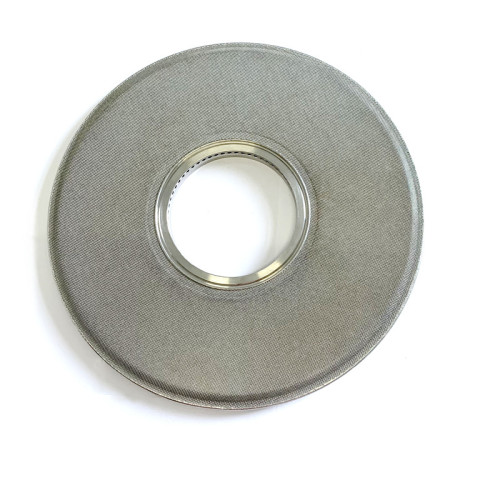

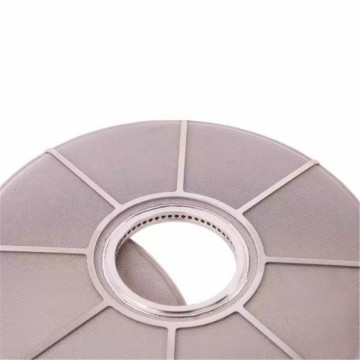

Sintered Stainless Steel Fiber Leaf Disc Filter

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu China |

|---|---|

| Productivity: | 30000pcs per month |

| Supply Ability: | 3000pcs per month |

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001,SGS,ROHS |

| HS Code: | 73141400 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo |

The main purpose of the leaf disc filter in polymer film filtration is to remove impurities, contaminants and particles from the polymer melt or solution prior to the film forming process. This helps to ensure the production of high-quality and defect-free polymer films.

Material :316L, 310S Filter Rating :3-200μm

Size :4.3 "7" 8.75 "10" 12 "(customizable)

Origin: Suzhou, Jiangsu Province

Features: strong filtration capacity, can adjust the filtration area, filter surface and large flow, high filtration rating, can be cleaned and used repeatedly.

Product description;

The fusant filter disc is also called leaf filter disc , which is used to filter the high viscosity melt. The polymer leaf disc filter makes effective filtration area per cubic meter large, and realizes the effective utilization of space and the miniaturization of the filtration device. The main material is made of stainless steel sintered felt or multi-layer stainless steel wire mesh.

Leaf disc filter is divided into two kinds, according to the material is divided into: stainless steel sintered felt, stainless steel sintered wire mesh; According to the structure, it is divided into soft seal (center ring wrapping edge type) and hard seal (center ring welding type). Among the above types, the biggest advantage of stainless steel sintered wire mesh filter material is high strength and impact resistance, but the amount of pollution is low, and the advantage of sintered felt is that the amount of pollution is large, the service cycle is strong, and the air permeability is good.

Application field;

1, lithium battery membrane melt filtration;

2, 2, carbon fiber melt filtration;

3, BOPP bidirectional tensile polypropylene film melt filtration;

4, BOPA bidirectional stretch nylon film melt filtration;

5, BOPET bidirectional stretch polyester film melt filtration;

6, high viscosity melt filtration;

FAQ

Q1: Are you factory/manufacturer or trader ?

We are direct factory who owns production lines and workers. Everything if flexible and there is no need to worry about extra charges by the middle person or trader.

Q2 : which countries do you export to ?

We are supporting worldwide customers cause we can export directly .

Q3 : Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4 : Do you support custom-make service ?

Yes, OEM&ODM service highly welcomed

Q5 : What is your minimum order quantity ?

Actually there is no MOQ for our products .But usually we recommend a quantity based on the price which is easy to accept and trial order also support .

Q6 : How long is your delivery time?

Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q7: What is your terms of payment ?

100% in advance is preferred for the 1st order.

30% T/T in advance ,70% balance before shipment.

Other payment terms are negotiable .

Related Keywords