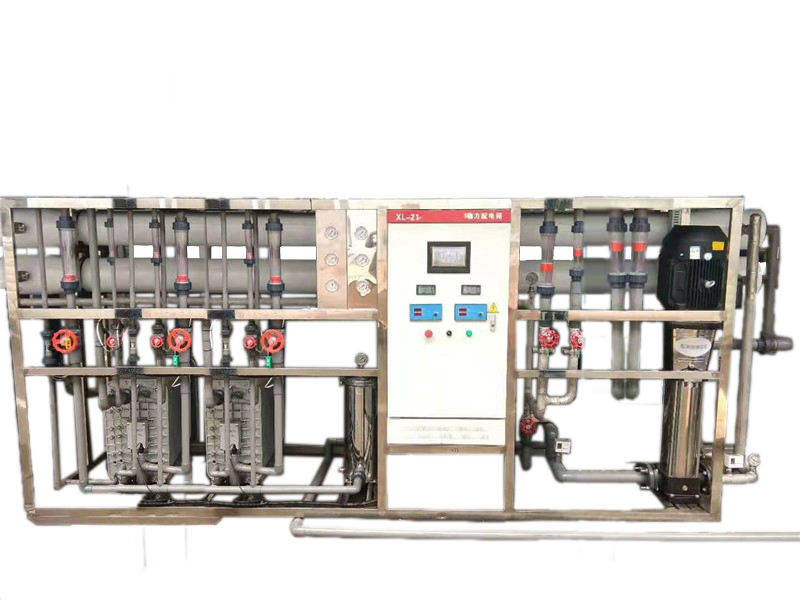

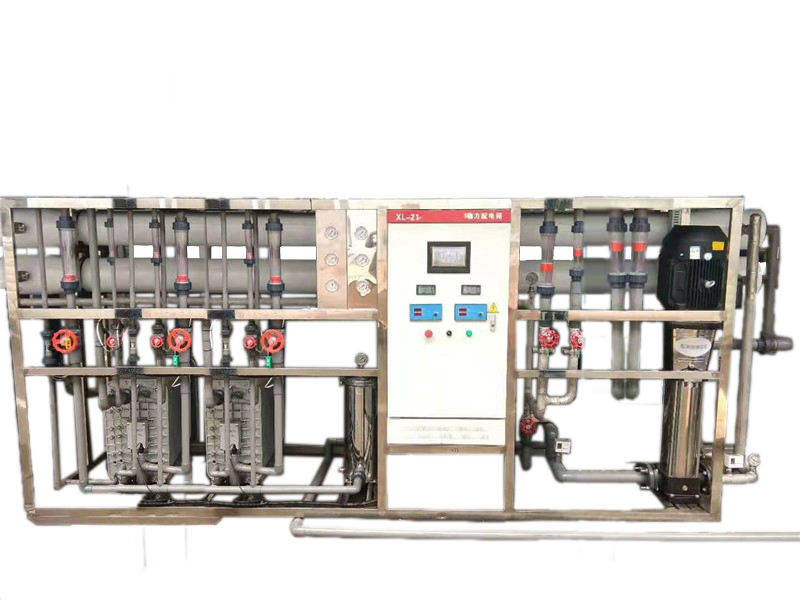

EDI Secondary Reverse Osmosis Polishing Resin Equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghaigang

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China Jiangsu |

|---|---|

| Productivity: | 200 sets |

| Supply Ability: | Annual output of 200 sets of water treatment equipment or even more |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | AAA certification |

| Transportation: | Ocean,Land |

| Port: | Shanghaigang |

Product Description

Product Description

Product Description

The EDI ultra-pure water equipment designed by our company adopts mature, reliable and highly automated secondary reverse osmosis + EDI + fine mixed bed desalination treatment process to ensure the quality of the ultra-pure water after treatment to ensure that the resistivity of the treated water reaches 18.2 MΩ. cm. The key equipment and materials of EDI ultrapure water equipment adopt reliable products and adopt PLC + touch screen control. The complete system has a high degree of automation and high system stability. Greatly save labor cost and maintenance cost, high water utilization rate, reliable operation, economical and reasonable. Compared with other similar products, the equipment has higher cost performance and equipment reliability.

Advantages of EDI ultrapure water equipment system

1. No need for acid-base regeneration: The resin in the mixed bed needs to be regenerated with chemicals and acid-base, and a workshop for safe storage of acid and base is required. During regeneration, there is a large amount of harmful wastewater and waste to be treated, which increases the difficulty of environmental protection and safety. . And EDI eliminates the handling and heavy work of these harmful substances. Protect the environment.

2. Continuous and simple operation: In the mixed bed, the operation process becomes complicated due to each regeneration and water quality change, while the water production process of EDI is stable and continuous, and the water quality is constant without complexity The operation procedure is greatly simplified.

3. Reduced installation requirements: EDI system has a smaller volume compared to a mixed bed with a considerable amount of processed water. It adopts a modular structure and can be flexibly constructed according to the height and scent of the site. The modular design makes EDI easy to maintain during production.

Application fields of EDI ultrapure water equipment system

1. Chemical water treatment in power plants

2. Ultrapure water in the electronics, semiconductor, and precision machinery industries

3. Preparation of food, beverages and drinking water

4. Small pure water station, drinking pure water for groups

5. Water for fine chemicals and sophisticated disciplines

6. Preparation of high-purity water required by other industries

7. Process water in the pharmaceutical industry

8. Desalination of sea water and brackish water

Advantages of EDI ultrapure water equipment system

1. No need for acid-base regeneration: The resin in the mixed bed needs to be regenerated with chemicals and acid-base, and a workshop for safe storage of acid and base is required. During regeneration, there is a large amount of harmful wastewater and waste to be treated, which increases the difficulty of environmental protection and safety. . And EDI eliminates the handling and heavy work of these harmful substances. Protect the environment.

2. Continuous and simple operation: In the mixed bed, the operation process becomes complicated due to each regeneration and water quality change, while the water production process of EDI is stable and continuous, and the water quality is constant without complexity The operation procedure is greatly simplified.

3. Reduced installation requirements: EDI system has a smaller volume compared to a mixed bed with a considerable amount of processed water. It adopts a modular structure and can be flexibly constructed according to the height and scent of the site. The modular design makes EDI easy to maintain during production.

Application fields of EDI ultrapure water equipment system

1. Chemical water treatment in power plants

2. Ultrapure water in the electronics, semiconductor, and precision machinery industries

3. Preparation of food, beverages and drinking water

4. Small pure water station, drinking pure water for groups

5. Water for fine chemicals and sophisticated disciplines

6. Preparation of high-purity water required by other industries

7. Process water in the pharmaceutical industry

8. Desalination of sea water and brackish water

Related Keywords

Related Keywords