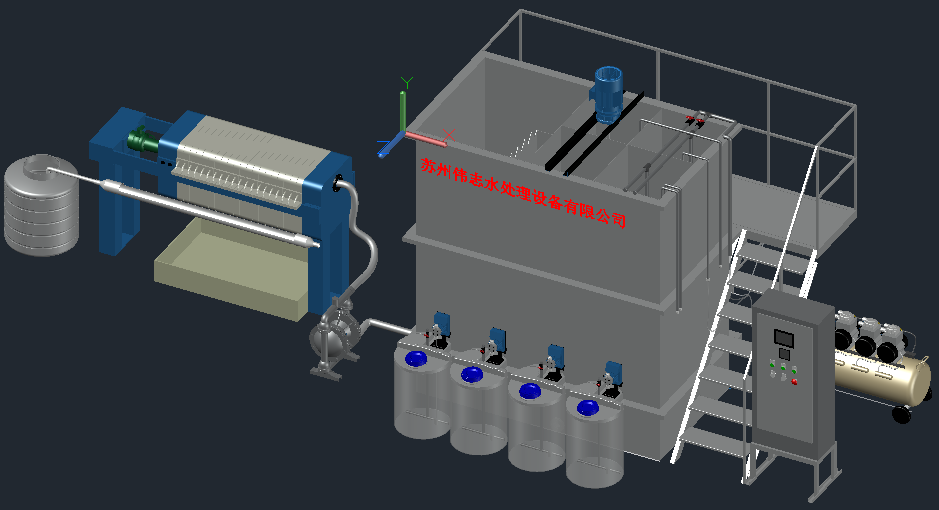

Electroplating Wastewater Treatment Equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shanghaigang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China Jiangsu |

|---|---|

| Productivity: | 200 sets |

| Supply Ability: | Annual output of 200 sets of water treatment equipment or even more |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | AAA certification |

| Transportation: | Ocean,Land |

| Port: | shanghaigang |

Product Description

Electroplating: The source of this type of sewage is mainly the sewage produced by the electrochemical reaction of metal and non-metal raw materials. The sewage is characterized by containing a variety of heavy metals, as well as acids, alkalis and cyanogens, which are harmful to the environment. The method adopted for this type of sewage is mainly classified physical and chemical treatment, that is, first stop the collection and pre-treatment of the cyanide-containing sewage, chromium-containing sewage, nickel-copper-zinc-containing sewage, and acid-base sewage in the electroplating production section to remove heavy metals in the sewage. , And then mix the treated sewage with domestic sewage, stop the biological treatment, after hydrolysis acidification, contact oxidation, sedimentation tank, filtration and conditioning, partially stop reuse in the plant area, and partially enter the park sewage pipe network and stop centralized disposal. Cyanide-containing wastewater pre-treatment technologies include electrolysis, activated carbon adsorption, ozone oxidation, ferrous sulfate, and ion exchange. Among them, electrolysis is the most common method. Sewage has an electrode oxidation reaction under alkaline electrode conditions, and the cyanide ions in the sewage are converted into nitrogen and carbon dioxide to remove the cyanide in the sewage. The pre-treatment technology of chromium-containing sewage includes chemical recovery method, electrolysis method, activated carbon adsorption method, evaporation concentration method, ion exchange method, and surface active agent method. Among them, the chemical restoration method is the most common. The high-valent chromium in the sewage is first restored to low-valent chromium by sulfur dioxide, sulfite and other substances, and then the chromium in the sewage is converted into chromium hydroxide precipitation under alkaline conditions, and the sewage is separated. Chromium.

Textile printing and dyeing: The main source of this type of wastewater is wastewater generated in the printing and dyeing, sizing, scouring and bleaching sections. The wastewater is characterized by containing a variety of chemical dyes, surface active agents, acid and alkali, oil agents, high chroma, and low pH value of wastewater. Stablize. This type of sewage treatment mainly adopts conditioning and hydrolytic acidification technology to adjust the pH value of the sewage, then stops the biological treatment, and then stops the flocculation precipitation and decolorization, such as the use of SBR technology + flocculation technology, oxidation ditch + flocculation technology, common flocculants such as sulfurous acid Iron, polyaluminum chloride, polyacrylamide. After hydrolysis and acidification, using SBR technology + flocculation sedimentation technology, the COD value of sewage is reduced from 800~1500mg/L at the inlet to 35~55mg/L at the outlet, and the BOD value is reduced from 170~300mg/L at the inlet to 8.1~ at the outlet. 10.3mg/L, the sewage chromaticity value is reduced from the initial 600~900 to 5~9, the treatment effect is better.

Suzhou Weizhi Water Treatment Equipment Co., Ltd. was established in 2008. The company has more than ten years of water treatment technology. It is a professional water treatment equipment company in Suzhou. By the end of 2019, water treatment technology has successfully implemented more than 1500 projects at home and abroad, with equipment treatment capacity of more than 60000 tons / day, and has solved water problems for more than 1500 customers, Industries involved: environmental protection, chemical industry, machinery, medicine, electronics, food, community water and other equipment; The company's existing production equipment: wastewater treatment equipment, reclaimed water reuse equipment, ultra pure water equipment, pure water equipment, evaporation equipment, etc; R & D projects: treatment of waste leachate, seawater desalination, application and development of energy recovery device, remote data acquisition of sewage treatment equipment and guidance tips for on-site practical application. Patents: at present, the company has 3 invention patents, 12 practical patents and 13 software patents. In addition, the company provides customers with fast and high-quality services with complete production and manufacturing plants, perfect design, excellent construction quality and perfect after-sales service quality. With the successful practice of thousands of projects, the company has extremely rich experience in design, implementation and operation.

Related Keywords