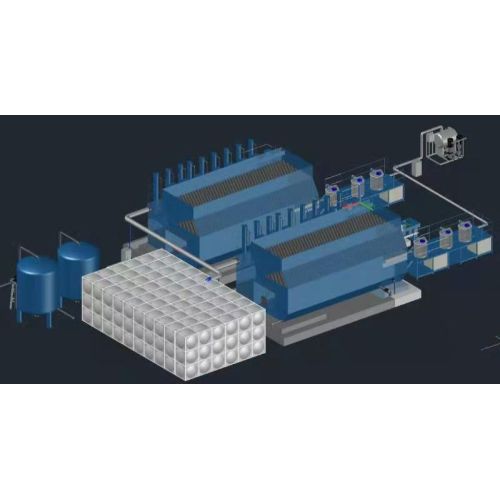

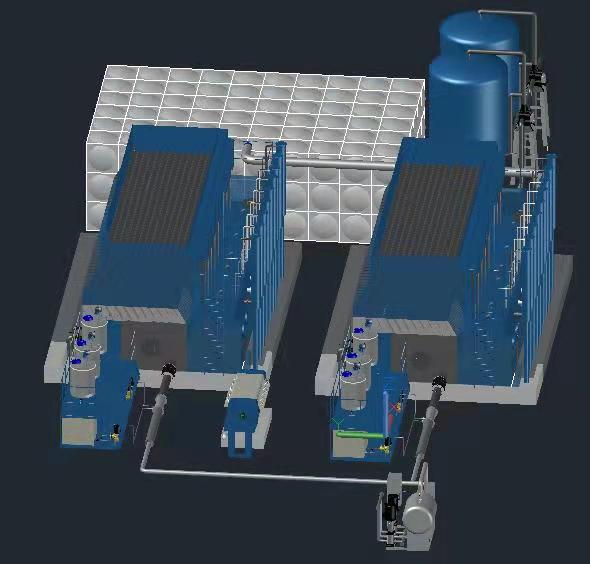

Electroplating Integrated Pure Water Treatment Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghaigang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China Jiangsu |

|---|---|

| Productivity: | 200 sets |

| Supply Ability: | Annual output of 200 sets of water treatment equipment or even more |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | AAA certification |

| Transportation: | Ocean,Land |

| Port: | Shanghaigang |

Product Description

The ultrapure water equipment provided in the electroplating industry meets the requirements of the Ministry of Electronics for the quality of ultrapure water. It can be divided into four levels: 15MΩ×cm, 10MΩ×cm, 5MΩ×cm, and 1MΩ×cm. The ultra-pure water equipment used in the electroplating industry can also adopt advanced reverse osmosis technology and use EDI desalination technology to prepare deionized water. Different ultra-pure water equipment units will be used according to different water quality requirements, which can meet the different levels of water quality standards required by users .

In the electroplating coating industry, in order to increase the surface finish, brightness, and adhesion of the plated parts, the preparation of the electroplating solution requires pure water with a conductivity of 15uS/cm or less, and a conductivity of 10uS/cm is also required when rinsing the plated parts. The following pure water is used for cleaning. The electroplating industry water treatment system includes the pure water treatment system required for the preparation of the electroplating solution before electroplating, and the rare metal recovery and rinsing water recycling wastewater zero discharge system in the electroplating rinsing wastewater. Usually the system is composed of ultrafiltration device, reverse osmosis device, ion exchange device, EDI device, etc. to meet the water quality requirements of the electroplating industry.

Electroplating Integrated Pure Water Treatment Machine in the electroplating industry use advanced technology, which is suitable for production lines of various large, medium and small enterprises. It can separate the metal ions in the raw water, and directly return to the rinsing tank for recycling, and the metal ions will be directly added to the electroplating tank after being concentrated. Compared with traditional electroplating rinsing, it completely changes the original technical treatment method, ensures the stability of water quality, reduces sewage costs for enterprises, creates economic benefits, improves product quality, and has the advantages of cleanliness and environmental protection.

1. Features of electroplating ultrapure water equipmentThe traditional preparation process of ultrapure water used in the electroplating industry is usually prepared by ion exchange resin, but the use of ion exchange resin usually requires frequent resin regeneration, which consumes material resources and wastes labor. Our company has gone through many years of practice and combined with new Membrane separation technology often uses reverse osmosis plus ion exchange system (or EDI) to prepare ultrapure water. Compared with the traditional process, this process has the advantage of low operating cost (the regeneration cycle of the ion exchanger is greatly extended). Reliable operation. Compared with the new process, it has the advantages of low cost and easy availability of consumables. The reverse osmosis technology is advanced and reliable.

2. Process flow for preparing ultrapure water for electroplating industry:

The process of preparing ultrapure water in the electroplating industry can be roughly divided into the following categories:

1. Using ion exchange method, the process is as follows:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → cation resin filter bed → anion resin filter bed → anion and yang resin mixed bed → microporous filter → water point

2. The two-stage reverse osmosis method is adopted, and the process is as follows:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → primary reverse osmosis → PH adjustment → intermediate water tank → secondary reverse osmosis (the surface of the reverse osmosis membrane is positively charged) → purified water tank →Pure water pump→Microporous filter→Water point

3. The EDI method is adopted, and the process is as follows:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → primary reverse osmosis machine → intermediate water tank → intermediate water pump → EDI system → microporous filter → water point

Ultrapure water quality standard

Related Keywords