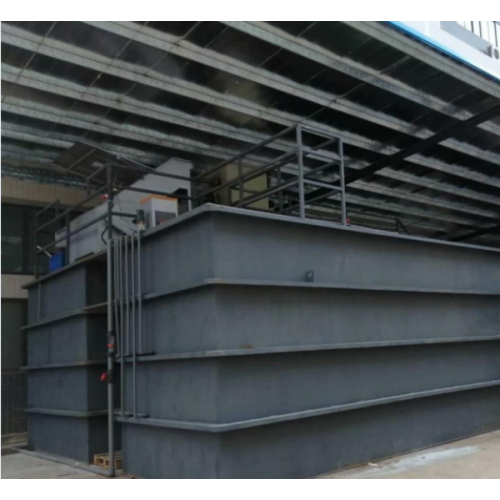

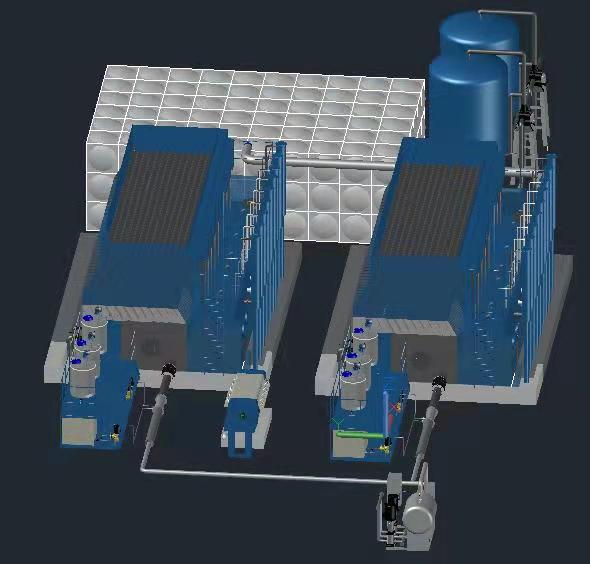

Small and Medium-sized Integrated Pure Water Equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghaigang

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China Jiangsu |

|---|---|

| Productivity: | 200 sets |

| Supply Ability: | Annual output of 200 sets of water treatment equipment or even more |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | AAA certification |

| Transportation: | Ocean,Land |

| Port: | Shanghaigang |

Product Description

Product Description

Product Description

Small and medium-sized integrated pure water equipment is the main water supply equipment for industrial production. Maintenance is an important condition for maintaining its stable operation. Small and medium-sized integrated pure water equipment mainly relies on reverse osmosis membranes to filter impurities, bacteria and other microorganisms in the water. After the integrated pure water equipment has been used for a period of time, the reverse osmosis membrane will become fouled. At this time, the user can use clean water or gas-water mixture to flush forward, and choose different backflushing pressure and flow rate according to the degree of clogging of the reverse osmosis membrane. And duration.

This method is effective for initial clogging and is suitable for clogging dominated by organic colloids. In addition, chemical cleaning can also be carried out. Chemical cleaning can be cleaned with acid cleaning agents, alkaline cleaning agents, enzyme cleaning agents, surfactants, complexing agents, disinfectants, and compounding agents. The cleaning effect and the type of cleaning agent, Concentration, temperature, PH value, etc. are related. Among them, cleaning equipment is one of the important items for maintenance, so how does the pure water equipment have a better cleaning effect?

Next, learn about the cleaning steps of pure water equipment:

The first step is to configure the cleaning fluid first. Add the agent to deionized water to ensure that the solution is thoroughly mixed and uniform, and then adjust the temperature and pH to the desired value.

The second step is to input the cleaning fluid at a low flow rate. First mix the cleaning fluid with the cleaning water pump, and then replace the raw water inside the component with the lowest possible cleaning fluid pressure. At this time, the pressure must be low enough to not produce obvious permeation water. Low-pressure replacement can greatly reduce the probability of dirt depositing on the membrane surface, and a low flow rate should be used when preheating the cleaning solution.

The third step is looping. When the raw water is replaced, the cleaning fluid should appear in the pipeline, allowing the cleaning fluid to circulate to the cleaning water tank, and at the same time ensuring a constant temperature of the cleaning fluid.

The fourth step is soaking. To stop the cleaning pump, the membrane element should be completely immersed in the cleaning solution for about an hour. For more stubborn pollutants, the soaking time should be prolonged appropriately, and it can even be soaked for 10-15 hours or soaked overnight. In order to maintain the temperature of the soaking process at this time, a very low circulating flow rate can be used.

The fifth step is to circulate the high-flow water pump. After soaking, use a high-flow water pump to circulate to ensure that the washed contaminants are washed away. The sixth step is to rinse. Use deionized water to flush the equipment at low pressure. When flushing the cleaning fluid in the system, it can be flushed with pre-processed qualified water. At the same time, in order to prevent the precipitation of contaminants, the minimum flushing temperature should be 20 degrees.

The above is about the cleaning steps of small and medium integrated pure water equipment. Regular cleaning can not only ensure the stable water production of small and medium integrated pure water equipment, but also effectively extend the service life of the reverse osmosis membrane and greatly save The cost of running.

This method is effective for initial clogging and is suitable for clogging dominated by organic colloids. In addition, chemical cleaning can also be carried out. Chemical cleaning can be cleaned with acid cleaning agents, alkaline cleaning agents, enzyme cleaning agents, surfactants, complexing agents, disinfectants, and compounding agents. The cleaning effect and the type of cleaning agent, Concentration, temperature, PH value, etc. are related. Among them, cleaning equipment is one of the important items for maintenance, so how does the pure water equipment have a better cleaning effect?

Next, learn about the cleaning steps of pure water equipment:

The first step is to configure the cleaning fluid first. Add the agent to deionized water to ensure that the solution is thoroughly mixed and uniform, and then adjust the temperature and pH to the desired value.

The second step is to input the cleaning fluid at a low flow rate. First mix the cleaning fluid with the cleaning water pump, and then replace the raw water inside the component with the lowest possible cleaning fluid pressure. At this time, the pressure must be low enough to not produce obvious permeation water. Low-pressure replacement can greatly reduce the probability of dirt depositing on the membrane surface, and a low flow rate should be used when preheating the cleaning solution.

The third step is looping. When the raw water is replaced, the cleaning fluid should appear in the pipeline, allowing the cleaning fluid to circulate to the cleaning water tank, and at the same time ensuring a constant temperature of the cleaning fluid.

The fourth step is soaking. To stop the cleaning pump, the membrane element should be completely immersed in the cleaning solution for about an hour. For more stubborn pollutants, the soaking time should be prolonged appropriately, and it can even be soaked for 10-15 hours or soaked overnight. In order to maintain the temperature of the soaking process at this time, a very low circulating flow rate can be used.

The fifth step is to circulate the high-flow water pump. After soaking, use a high-flow water pump to circulate to ensure that the washed contaminants are washed away. The sixth step is to rinse. Use deionized water to flush the equipment at low pressure. When flushing the cleaning fluid in the system, it can be flushed with pre-processed qualified water. At the same time, in order to prevent the precipitation of contaminants, the minimum flushing temperature should be 20 degrees.

The above is about the cleaning steps of small and medium integrated pure water equipment. Regular cleaning can not only ensure the stable water production of small and medium integrated pure water equipment, but also effectively extend the service life of the reverse osmosis membrane and greatly save The cost of running.

Related Keywords

Related Keywords