material handling equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- Shagnhai

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 500 Set/Sets per Month |

|---|---|

| Payment Type: | T/T |

| Port: | Shagnhai |

The application of material handling machinery is of great significance in production, mainly because the amount of material handling is very large. For every ton of steel produced by some iron and steel complexes, the total amount of raw materials, fuels, semi-finished products, finished products and wastes that need to be handled Often more than 50 tons; in addition, the cost of material handling is high, and the cost of material handling in industrial countries often accounts for about 25% of the product cost; material handling takes up a lot of labor, and in enterprises with a low degree of mechanization, porters often It accounts for more than 15% of the total number of workers; when carrying heavy objects that cannot be carried by human beings and working in areas with high temperature or radioactive substances, they must be carried by machinery. Therefore, sufficient attention should be paid to the material handling system in production, and advanced and applicable material handling machinery should be used as much as possible to reduce labor intensity, reduce product damage, protect workers' health, improve labor productivity and product quality, and reduce production costs.

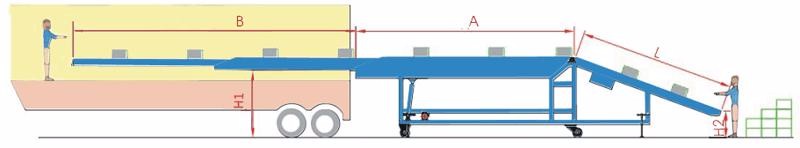

Main Features

1.Adjustable:you can adjust buttons according to your own requirements to control the length of the conveyor. If the machine is equipped with a lifting device, you can also control its end height at any time. It can finish loading and unloading by pulling the goods just beside operating personnel. You can load the goods if the belt turning forward and unload goods if the belt turning reversely. Its handling efficiency can reach 30 pieces per minute.

2.Reduce cost: it greatly shortens the distance of carrying materials by labor. It reduces the lay time , labor intensity and the damage to goods so that you can reduce handling cost and improve work efficiency.

3.Flow operation:it can load and unload the goods stably and continuously to avoid messy phenomenon and ground operation all around.

4.Safety operation: It reduces the accidents caused by extensive fatigue of unloading and unloading goods by labor.

Related Keywords