High Purity Industrial VPSA Oxygen Generator Plant

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO |

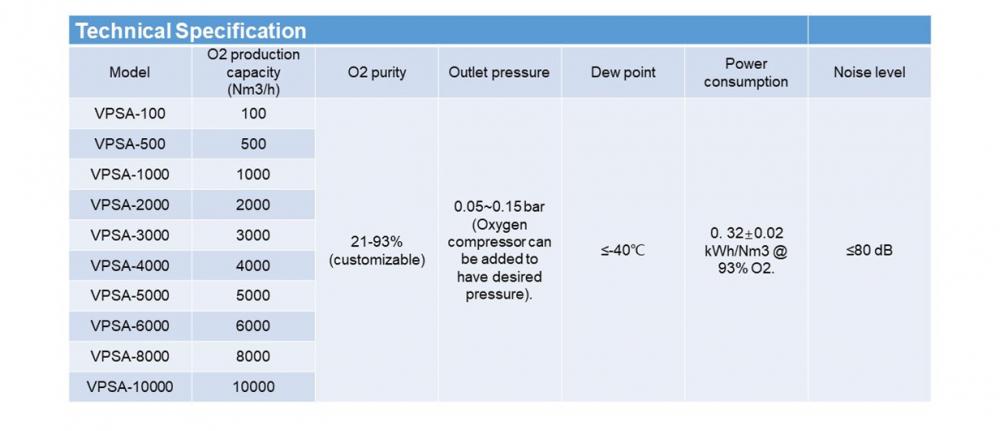

KEY TECHNICAL PARAMETERS

Model: VPSA-6000.

O2 flow rate: ≥6000 Nm3/h (customizable).O2 purity: 21-93% (vol) (customizable).

0.05~0.15 bar (Oxygen compressor can be added to have desired pressure).

Power supply: AC 380 V.

Power consumption: 0.32±0.02 kWh/Nm3@93% O2.

Noise level: ≤80 dB (@1 m).

Start-up time: ≤30 min.

MTBF: 8400 h/a.

Operating mode: continuous.

Life time of adsorbent: 10 years.

Life time of valve seals: 2 million times openning and closing.

Design life of static equipment (adsorber towers etc.): 15 years.

TECHNICAL SPECIFICATION

(Cryogenic Storage tanks, Large Scale Flat Bottom Cryogenic Liquid Storage tanks, PSA Oxygen Plant, VPSA Oxygen Plant, Cryogenic Air Separation Units, Air Heated Vaporizers, Water Bath Vaporizers)

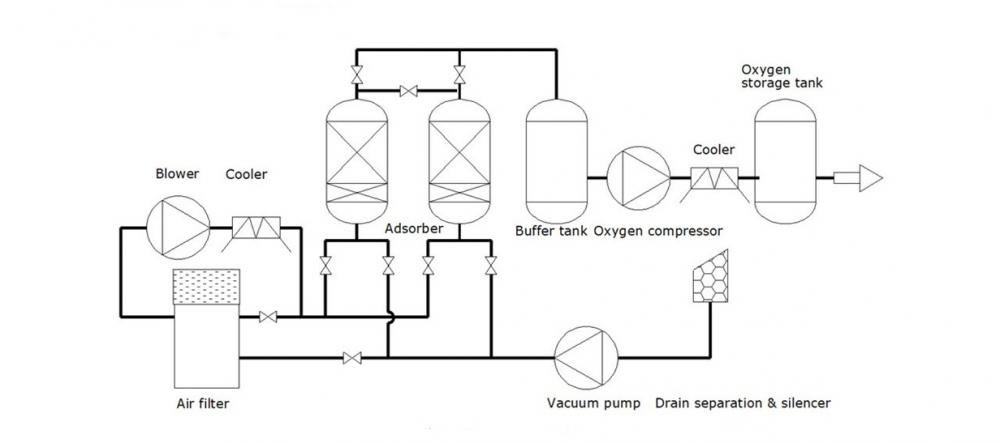

SCHEMATIC DIAGRAM

Air filter->Blower->Cooler->Adsorber(->Vacuum pump)->Buffer tank->Oxygen compressor->Cooler->Oxygen storage tank.

Vacuum Pressure Swing Adsorption (VPSA) technology can produce the desired gas(es) much more efficiently. The system segregates certain gases from a gaseous mixture at near ambient pressure; the process then swings to a vacuum to regenerate the adsorbent material, zeolite molecular sieves. It draws the gas through the separation process with a vacuum, typically generated by a blower, The systems apply pressurized gas to the separation process and also apply a vacuum to the purge gas.

PAST PROJECTS

FEATURES & BENEFETS

Easy to operate.

Pre-fabricated skids, fast start-up.

High degree of automation, one-key start/stop.Little work of maintenance.

Long service time, design life of 15-25 years.

Low power consumption.

Unique air distribution system.

High energy utilization rate.

Low cost for on-site production.

APPLICATIONS

Agricultural products manufacturing, Aircraft & aerospace applications, Chemical processing, Cosmetics processing, Cutting & welding, Environmental protection, Food and beverage processing, Glass, ceramics, other minerals, Medical gas therapy, Metallurgy, Mining operations, Oil and fuel processing, Plastic processing, Pharmaceutical processing, Power generation, Pulp and paper processing, Rubber, plastics, paint, Underwater diving, Water treatment / industrial water treatment, Etc.

WHY US?

• Professional & experienced teams.

State-of-art technologies, focusing on innovation & staff training.

Over 12 years in the industry, one of the most fast-growing.

• One-stop solution.

Integrated service of design, manufacture, delivery, erection, commissioning & more.

A wide range of products, accessories inclusive, four manufacturing bases across China.

• Preeminent product quality.

Certified by multiple international authorities/organizations.

High operational stability with top quality components.

• Customer oriented.

Custom made solutions for practical difficulties.

Cost-effective, win-win business development.

INTEGRATED SERVICE

Inquiry->Solution->Agreement->Payment->Production->Delivery->Installation->Service

ABOUT US

China Doer Gas & Chemical Equipment Co., Ltd. Is one of the fastest growing corporation in the industry since its foundation in 2009 thanks to its advantages in excellent quality, technological innovation and heartfelt service. It now has set up four manufacturing bases across China, obtained over 60 patents and multiple international certificates, and is reaching out for more and more global customers with a wide range of products, standard or custom-made, covering cryogenic storage tanks, vacuum storage tanks, oxygen generator plant, cryogenic air separation equipment, liquefied gas vaporizers etc.

Related Keywords