Flat Bottom Storage Tanks For Storing LOX LIN,LAR

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO |

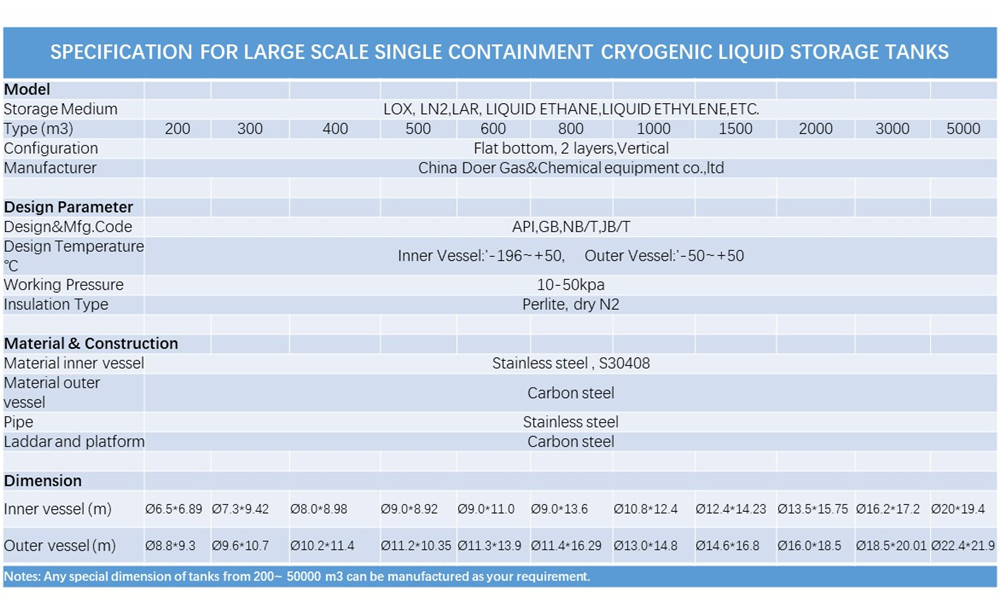

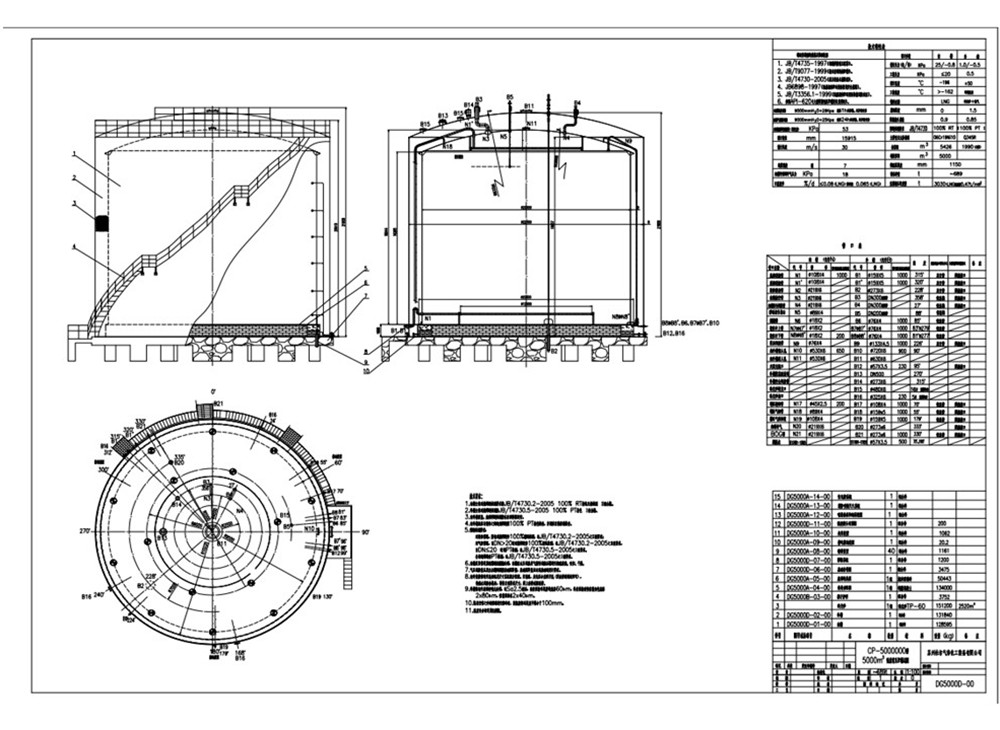

Specification for large flat bottom liquid industrial gas storage tanks

Gas types:LIQUID ETHANE, LIQUID ETHYLENE,

Type (m3): 600

Material inner vessel:Stainless steel,S30408

Material outer vessel:Carbon steel, Q235B

Pipe:Stainless steel

Laddar and platform:Carbon steel

Dimension:

Inner vessel (m) Ø9.0*11.0

Outer vessel (m) Ø11.3*13.9

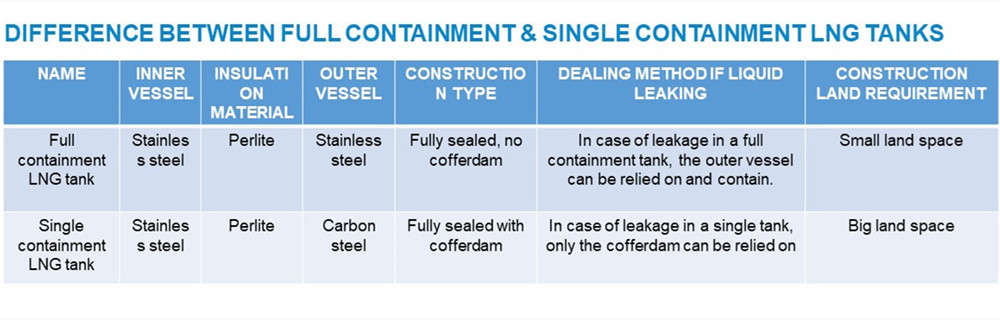

DIFFERENCE BETWEEN FULL CONTAINMENT & SINGLE CONTAINMENT LNG TANKS

(Cryogenic Storage Tanks, Large Scale Flat Bottom Cryogenic Liquid Storage Tanks, PSA Oxygen Plant, VPSA Oxygen Plant, Cryogenic Air Separation Units, Air Heated Vaporizers, Water Bath Vaporizers)

(Cryogenic Storage Tanks, Large Scale Flat Bottom Cryogenic Liquid Storage Tanks, PSA Oxygen Plant, VPSA Oxygen Plant, Cryogenic Air Separation Units, Air Heated Vaporizers, Water Bath Vaporizers)

TECHNICAL SPECIFICAITON

TYPICAL DESIGN DRAWING

PAST PROJECTS:

FACTORY TOURS

FEATURES

• Easy erection, pre-fabricated structures;

• Low power consumption, low operating cost;

• Simple operation, high degree of automation, intelligent control, highly flexible control;

• High operational stability, high safety, key components from well-known suppliers;

• Long service life, little work of maitenance, low maitenance costs;

APPLICATIONS

Agricultural products manufacturing, Aircraft & aerospace applications, Chemical processing, Cosmetics processing, Cutting & welding, Environmental protection, Food and beverage processing, Glass, ceramics, other minerals, Medical gas therapy, Metallurgy, Mining operations, Oil and fuel processing, Plastic processing, Pharmaceutical processing, Power generation, Pulp and paper processing, Rubber, plastics, paint, Underwater diving, Water treatment / industrial water treatment, Etc.

WHY US?

• Professional & experienced teams.

State-of-art technologies, focusing on innovation & staff training.

Over 12 years in the industry, one of the most fast-growing.

• One-stop solution.

Integrated service of design, manufacture, delivery, erection, commissioning & more.

A wide range of products, accessories inclusive, four manufacturing bases across China.

• Preeminent product quality.

Certified by multiple international authorities/organizations.

High operational stability with top quality components.

• Customer oriented.

Custom made solutions for practical difficulties.

Cost-effective, win-win business development.

INTEGRATED SERVICE

ABOUT US

China Doer Gas & Chemical Equipment Co., Ltd. Is one of the fastest growing corporation in the industry since its foundation in 2009 thanks to its advantages in excellent quality, technological innovation and heartfelt service. It now has set up four manufacturing bases across China, obtained over 60 patents and multiple international certificates, and is reaching out for more and more global customers with a wide range of products, standard or custom-made, covering cryogenic storage tanks, vacuum storage tanks, oxygen generator plant, cryogenic air separation equipment, liquefied gas vaporizers etc.

Related Keywords