2022 Oxygen Plant N2 and O2 Gaseous Plant

-

$185000.001-9 Piece/Pieces

-

$168800.0010-499 Piece/Pieces

-

$168.00≥500 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Set/Sets per Month liquid |

| Supply Ability: | 100 Set/Sets per Month liquid oxygen tank, liquid oxygen tank |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO14001/ISO9001/GB/ASME |

| HS Code: | 8419601100 |

| Transportation: | Ocean |

| Port: | Qingdao,Shanghai |

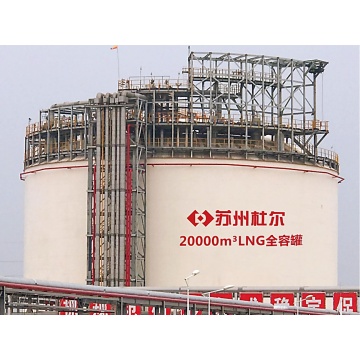

Details Images of air separation plant

Safety Filtration System

Production: oxygen up to 99.8% purity and 100 bar.

Advanced Cryogenic Porcess Design

More than 1200 references among which more than 75 units larger than 2000 tpd.

Large portfolio offer adapted to a wide range of industries.Reliable Pressure Vessel and Accurate Oxygen Purity Inspection.

Pressure and Flow Control

Capacity: up to 6 000 tons per day.

Reliable Valve Control and Stable SIEMENS PLC Control System.Optimized plants design depending on specific projects economics, geography, products, specifications, energy costs and customer

process integration potentials.

High degree of automation

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

Related Keywords