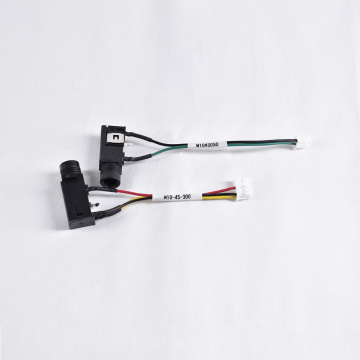

Medical Equipment Power Wire Loom

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000pieces/year |

| Supply Ability: | 1000000pieces/month |

| Payment Type: | L/C,T/T,D/P,Others |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery,DEQ |

| Certificate: | UL, IPC620, ISO9001, ISO14001, IATF14969, ISO13485 |

| HS Code: | 8544422100 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai,Ningbo |

When installing an electrocardiogram (ECG) machine, it is important to pay attention to the installation of the wire harness or wire looms that connect the patient to the machine. These wire assemblies are responsible for transmitting the electrical signals from the patient's heart to the ECG machine, so any errors or malfunctions in their installation can lead to inaccurate readings.

Here are some important considerations when installing ECG wiring harness:

1. Proper placement: Ensure that the wiring looms are placed in the correct positions on the patient's body, according to the manufacturer's instructions. Incorrect placement can lead to incorrect readings.

2. Secure attachment: The wiring assemblies should be firmly attached to the patient's skin using adhesive patches or clips. Loose wires can cause interference and lead to inaccurate readings.

3. Avoid interference: Keep the cable harnesses away from other electrical devices, such as cell phones or computers, which can cause interference and affect the accuracy of the readings.

4. Regular maintenance: Check the cable looms regularly for signs of wear or damage, and replace them as necessary. Damaged wires can cause inaccurate readings or even harm the patient.

By following these guidelines, you can ensure that your ECG machine is functioning properly and providing accurate readings for your patients.

Product name

Medical Equipment Power Wire Loom

Specification

Custom Cable & Wire Harness / OEM,ODM

Processing technology

Crimping, molding, forming, assembly, anti-static process

Connectors

Thousands different connectors available

Connector brand

TE, Molex, Amphenol, LEMO, JST, etc (or other equivalent).

Cable

According to the requirements of customers

MOQ

Sample order/small order can be accepted

R&D

Provide complete engineering and design services

Product certification

ISO 13485, ISO14001, ISO9001, IATF 16949, UL, IPC620, IMDS, ROHS

QC

Passed ISO 9001:2015 quality control system. All the products are 100% test before delivery. UL factory certificate of compliance.

Related Keywords