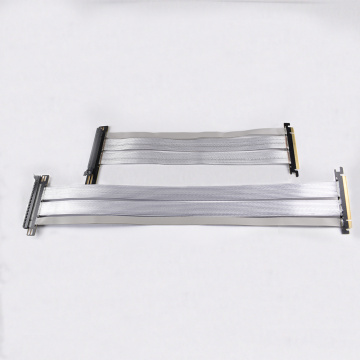

Battery Pack Wire Harness

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000pieces/year |

| Supply Ability: | 1000000pieces/month |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO 13485, ISO14001, ISO9001, IATF 16949, UL, IPC620, IMDS, ROHS |

| HS Code: | 8544601200 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo |

Battery pack wiring harness is an essential component in the design of electric vehicles. It is responsible for connecting the battery cells together and providing power to the motor and other electrical components. The wiring loom is made up of multiple wires that are insulated and bundled together to form a cohesive unit.

The wiring assembly plays a critical role in ensuring the safety and reliability of the battery pack. It is designed to handle high voltage and current levels, and must be able to withstand extreme temperatures and vibrations. The wire harness is also responsible for monitoring the status of the battery cells and ensuring that they are operating within safe limits.

The design of the wire loom is a complex process that involves careful consideration of factors such as wire gauge, insulation material, and connector type. The wire assembly must be designed to meet the specific requirements of the vehicle, including the voltage and current levels, as well as the physical constraints of the vehicle's layout.

In summary, the battery pack cable harness is a critical component in the design of electric vehicles. It plays a critical role in ensuring the safety and reliability of the battery pack, and must be carefully designed to meet the specific requirements of the vehicle.

Product name

Battery Pack Wire Harness

Specification

Custom Cable & Wire Harness / OEM,ODM

Processing technology

Crimping, molding, forming, assembly, anti-static process

Connectors

Thousands different connectors available

Connector brand

TE, Molex, Amphenol, LEMO, JST, etc (or other equivalent).

Cable

According to the requirements of customers

MOQ

Sample order/small order can be accepted

R&D

Provide complete engineering and design services

Product certification

ISO 13485, ISO14001, ISO9001, IATF 16949, UL, IPC620, IMDS, ROHS

QC

Passed ISO 9001:2015 quality control system. All the products are 100% test before delivery. UL factory certificate of compliance.

Related Keywords