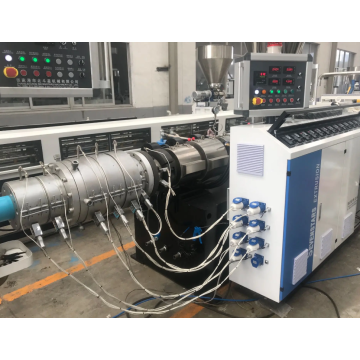

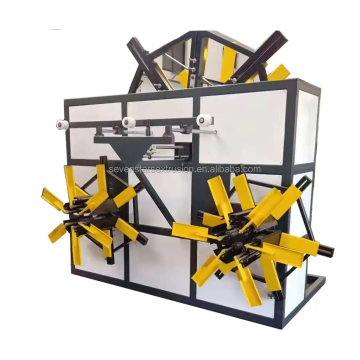

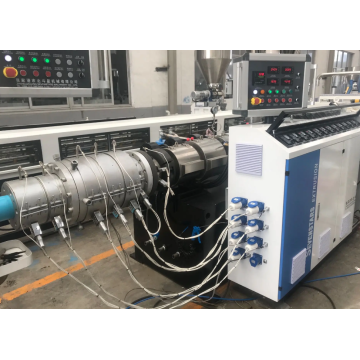

PP PE plastic Cable protect hose extrusion machine production line

-

$22000.001-4 Set/Sets

-

$20000.00≥5 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 30 Set/Sets per Quarter |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | Shanghai seaport |

Product Description

Product Description

PP PE plastic Cable protect hose extrusion machine production line

Plastic single wall corrugated pipes have features of high temperature resistance, corrosion and abrasion resiatance,high intensity and good flexibility,etc.they are widely used in fields of auto wire harness, electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lantern wires,tubes of air conditioner and washing machine,etc. Applications:plastic single wall corrugated pipe making machine can produce electrical thread-passing pipes,circuit of machine tool,protective pipe of lamps,water pipes in conditioner,washing machine, bathroom, etc.

Specification

Model of PP PE plastic Cable protect hose extrusion machine production line

|

Model

|

Pipe Diameter

|

Production Speed

|

Extruder Model

|

Main Motor Power

|

Mold Block Qty.

|

|

BDX-14

|

5-14mm

|

6-8m/min

|

SJ45/28

|

7.5kw

|

42 pairs

|

|

HG-32

|

10-32mm

|

5-12m/min

|

SJ50/30

|

15kw

|

50 pairs

|

|

HG-50

|

16-50mm

|

4-10m/min

|

SJ65/30

|

22kw

|

50 pairs

|

|

HG-63

|

16-63mm

|

4-10m/min

|

SJ65/30

|

30kw

|

50 pairs

|

|

HG-110

|

32-110mm

|

2-8m/min

|

SJ65/33

|

37kw

|

72 pairs

|

|

HG-160

|

50-160mm

|

2-5m/min

|

SJ75/30

|

45kw

|

72 pairs

|

|

HG-50 high speed

|

9-50mm

|

20-35m/min

|

SJ65/30

|

30kw

|

90pairs

|

Recommend Products

Recommended by seller

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

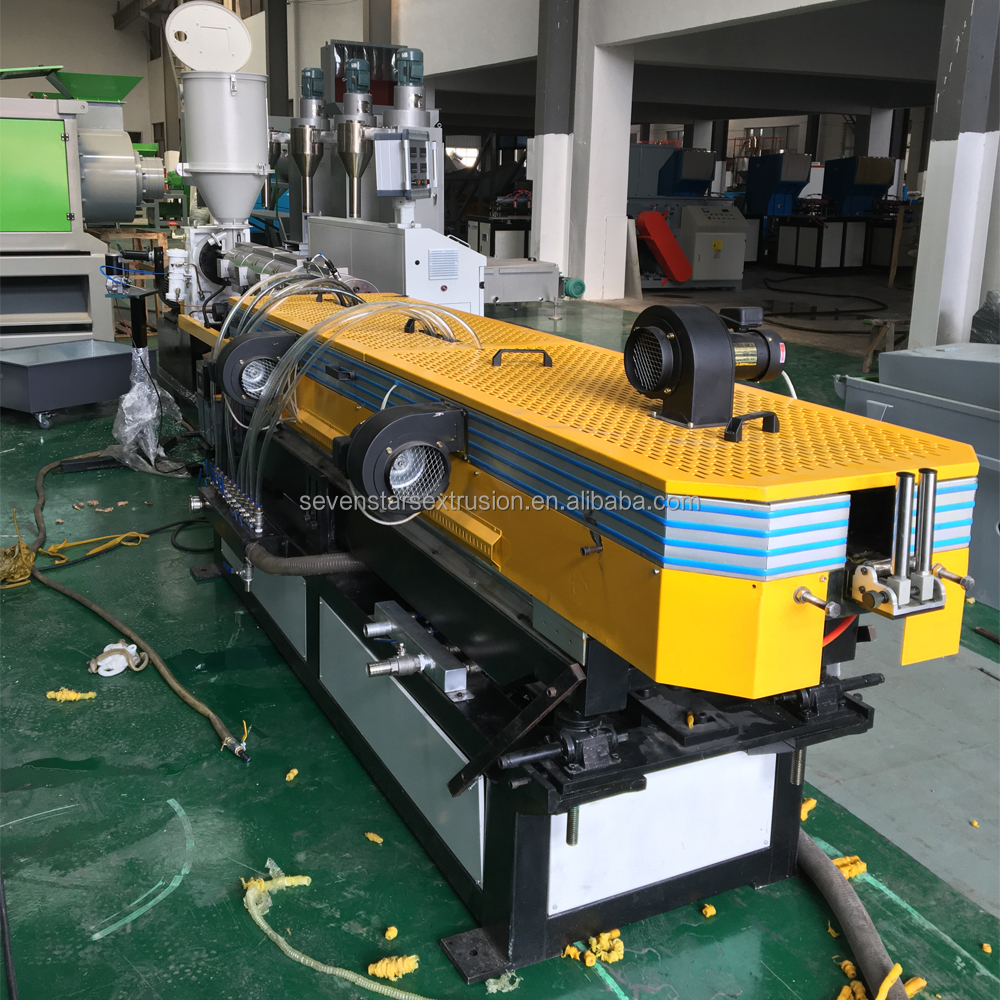

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords