PVC Gusset Sheet Machine Plastic Hollow Board Extruder

-

$22000.001-2 Set/Sets

-

$21000.003-4 Set/Sets

-

$20000.00≥5 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Quarter |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | shanghai seaport |

Product Description

Product Description

PVC Gusset Sheet Machine Plastic Hollow Board Extruder

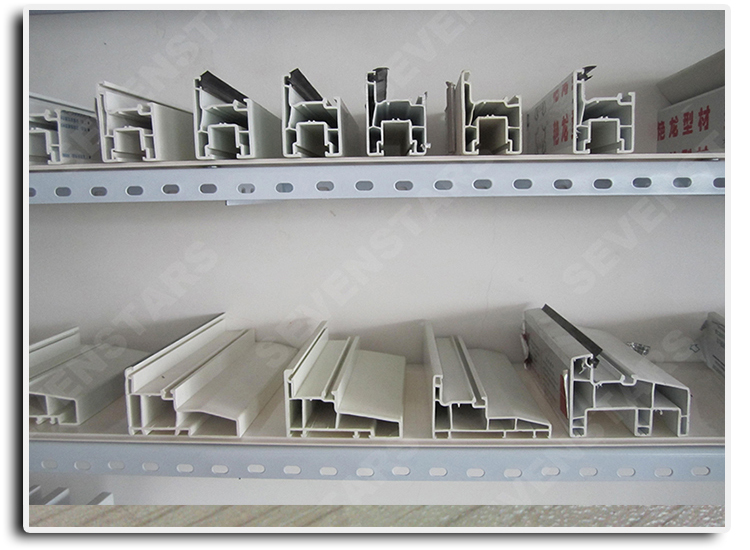

Products:PVC Gusset Sheet Machine For Sale,Ceiling Panel Line With Online Lamination,Plastic Gusset Hollow Board Extruder

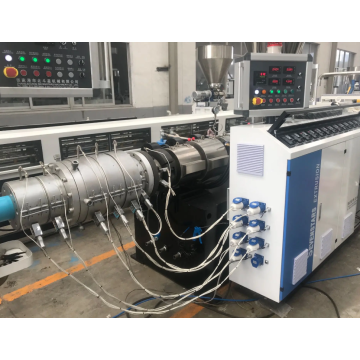

The PVC profile extrusion line is mainly used in the area of PVC plastics, WPC profile, decorative profile etc. The unit is

composed of conical twin-screw extruder, vacuum shaping table, haul-off machine, cutter, turning-up flame. According to the different profile's section and moulds, you can choose different specifications of extruders to fit. The vacuum shaping table adopts special eddy current system to enhance cooling effect. The unique control skills of horizontal tilt and three dimension regulations embody perfectly for convenient operation. According to the different moulds and shaping tables, you can select corresponding sizing tables to meet the requirement of high output.The tractor uses the unique fluctuation technology and back pressure control with caterpillars around it. The cutter's move speed keeps with the tractor. It can automatically cut for fixed length and it also equipped with powder recycle device.The line can be used to produce PVC door and window profile,door pocket,pvc cable channel, pvc wiring duct, skirting board, louver blade etc.

Feature:

1. The barrel is heated by aluminum casting hot wire ring and cooled by air cooling system, and the heat transfer is fast and uniform.

2. Different screws can be selected according to different formulas in order to achieve the best plasticizing effect.

3. The gear box & distribution box both adopt famous bearing, imported oil seal; gear wheel adopts high-quality alloy steel under nitrogen process

4. Special design of reducer and distribution box, reinforced thrust bearing, high transmission torque and long service life

5. The vacuum calibration table adopts a special enlarged swirl cooling system, which is convenient for cooling setting, and the special horizontal tilt control has a unique three-position adjustment control, which makes the operation simple and better

reflected

6. The haul-off machine adopts unique lifting technology, upper and lower crawler is controlled by back pressure, work stably,large reliability & traction force, can automatically fixed the length cutting, and is equipped with the dust recovery device

7. All the imported components are adopted to ensure the stability and reliability of the machine under continuous operation for a long time

composed of conical twin-screw extruder, vacuum shaping table, haul-off machine, cutter, turning-up flame. According to the different profile's section and moulds, you can choose different specifications of extruders to fit. The vacuum shaping table adopts special eddy current system to enhance cooling effect. The unique control skills of horizontal tilt and three dimension regulations embody perfectly for convenient operation. According to the different moulds and shaping tables, you can select corresponding sizing tables to meet the requirement of high output.The tractor uses the unique fluctuation technology and back pressure control with caterpillars around it. The cutter's move speed keeps with the tractor. It can automatically cut for fixed length and it also equipped with powder recycle device.The line can be used to produce PVC door and window profile,door pocket,pvc cable channel, pvc wiring duct, skirting board, louver blade etc.

Feature:

1. The barrel is heated by aluminum casting hot wire ring and cooled by air cooling system, and the heat transfer is fast and uniform.

2. Different screws can be selected according to different formulas in order to achieve the best plasticizing effect.

3. The gear box & distribution box both adopt famous bearing, imported oil seal; gear wheel adopts high-quality alloy steel under nitrogen process

4. Special design of reducer and distribution box, reinforced thrust bearing, high transmission torque and long service life

5. The vacuum calibration table adopts a special enlarged swirl cooling system, which is convenient for cooling setting, and the special horizontal tilt control has a unique three-position adjustment control, which makes the operation simple and better

reflected

6. The haul-off machine adopts unique lifting technology, upper and lower crawler is controlled by back pressure, work stably,large reliability & traction force, can automatically fixed the length cutting, and is equipped with the dust recovery device

7. All the imported components are adopted to ensure the stability and reliability of the machine under continuous operation for a long time

Product Description

PVC ceiling panel features

1.PVC ceiling panel are the ideal way to deliver tempered air from preheated hallways to farrowing or nursery rooms. The hollow profile acts as an air plenum delivering the air through precisely sized and positioned holes. The air enters the room uniformly without creating drafts.

2.it is light in weight, moisture resistant and reduces condensation and subsequent dripping from ceiling onto work surfaces. The cleanable, non-absorbent surface is UV stable and will not discolour.

3. solves the problem of dirty, unhygienic ceilings that are difficult, and expensive to clean by providing a bright, durable and hygienic surface, which is easily maintained. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

4.PVC ceilicing panel has various advantage over other materials namely they are waterproof, Termite Proof, Fire Retardant,Economical, Maintenance free, being non-porous and non-absorbent, can incorporate flush fitting lighting, access hatches, air vents and sprinklers easy to install & available in various colours shades & no hassles of Painting & Polishing.

2.it is light in weight, moisture resistant and reduces condensation and subsequent dripping from ceiling onto work surfaces. The cleanable, non-absorbent surface is UV stable and will not discolour.

3. solves the problem of dirty, unhygienic ceilings that are difficult, and expensive to clean by providing a bright, durable and hygienic surface, which is easily maintained. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

4.PVC ceilicing panel has various advantage over other materials namely they are waterproof, Termite Proof, Fire Retardant,Economical, Maintenance free, being non-porous and non-absorbent, can incorporate flush fitting lighting, access hatches, air vents and sprinklers easy to install & available in various colours shades & no hassles of Painting & Polishing.

Specification

Machine list of PVC gusset sheet machine for sale plastic gusset hollow board extruder ceiling panel line with online lamination

|

Item

|

Machine name

|

Quantity

|

|

1

|

Auto feeder

|

1 set

|

|

2

|

SJSZ65/132 extruder or other model

|

1 set

|

|

3

|

die head and mold

|

1 set

|

|

4

|

calibrating machine

|

1 set

|

|

5

|

hual off machine

|

1 set

|

|

6

|

cutting machine

|

1 set

|

|

7

|

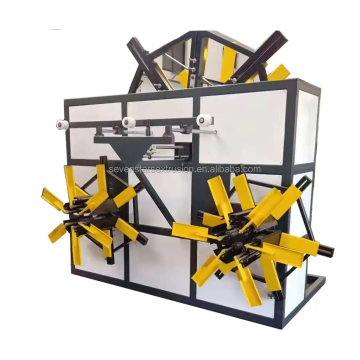

product stacker

|

1 set

|

|

8

|

electric control cabinet

|

1 set

|

Related Keywords

Related Keywords