600mm PVC False Ceiling Panel Sheet Machine Line

-

$25000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Port: | shanghai seaport |

Product Description

Product Description

600mm PVC False Ceiling Panel Sheet Machine Line

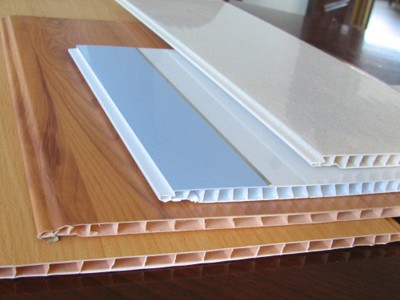

Complete pvc ceiling wall panel making machine / production line with online lamination line is used to produce PVC celing panel or PVC wall panel with width normally from 200mm to 300mm with different section shape and height. The surface of PVC ceiling panel can be treated by double by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

Production line including:

1.Auto loader for raw material ---1set

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

9.Auxilary equitment (mixer, crusher, pulverizer, color printer.etc )

Production line including:

1.Auto loader for raw material ---1set

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

9.Auxilary equitment (mixer, crusher, pulverizer, color printer.etc )

Details Images

Products: PVC False Ceiling Making Machine, PVC Sheet Making Machine Ceiling Panel, PVC False Ceiling Panel Machine

Products Description

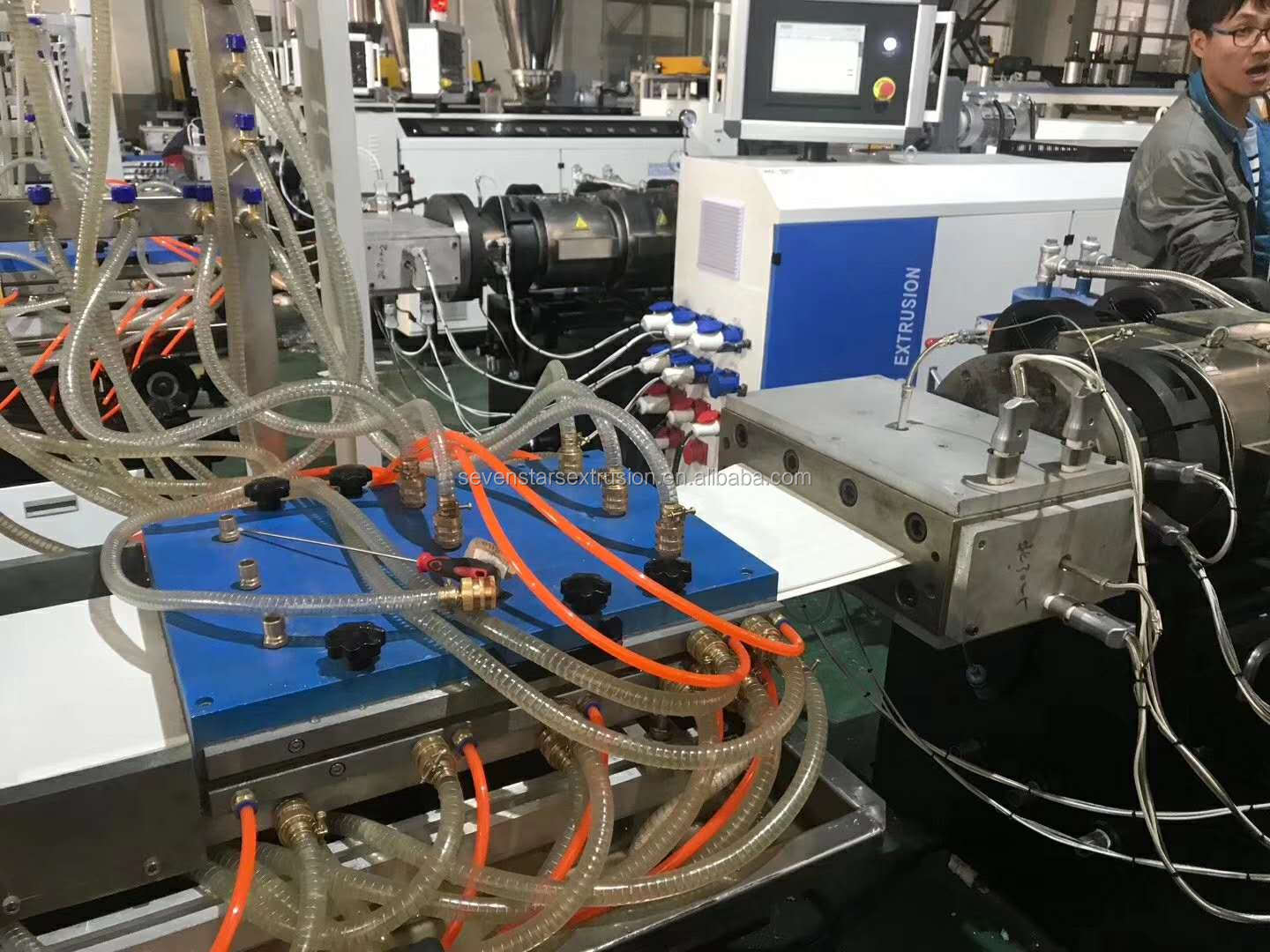

conical twin screw extruder

Mold

Vacuum cooling table

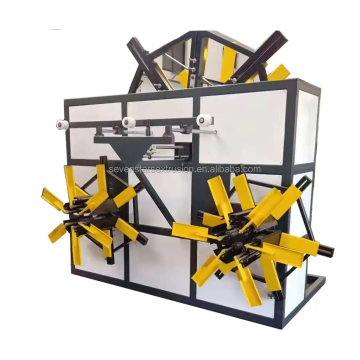

Hot stamping and laminating machine

Haul off machine

Cutting machine

Final Product

Product Paramenters

|

Model

|

48/113

|

55/110

|

65/132

|

80/156

|

|

Applicable product width

|

160-200mm

|

200-300mm

|

400-600mm

|

500-800mm

|

|

Extruder model

|

SJSZ48/118

|

SJSZ55/110

|

SJSZ65/132

|

SJSZ80/156

|

|

Capacity (kg/hour)

|

50-150kg/h

|

60-180kg/h

|

120-300kg/h

|

180-400kg/h

|

|

Main motor power(KW)

|

15

|

30

|

37

|

55

|

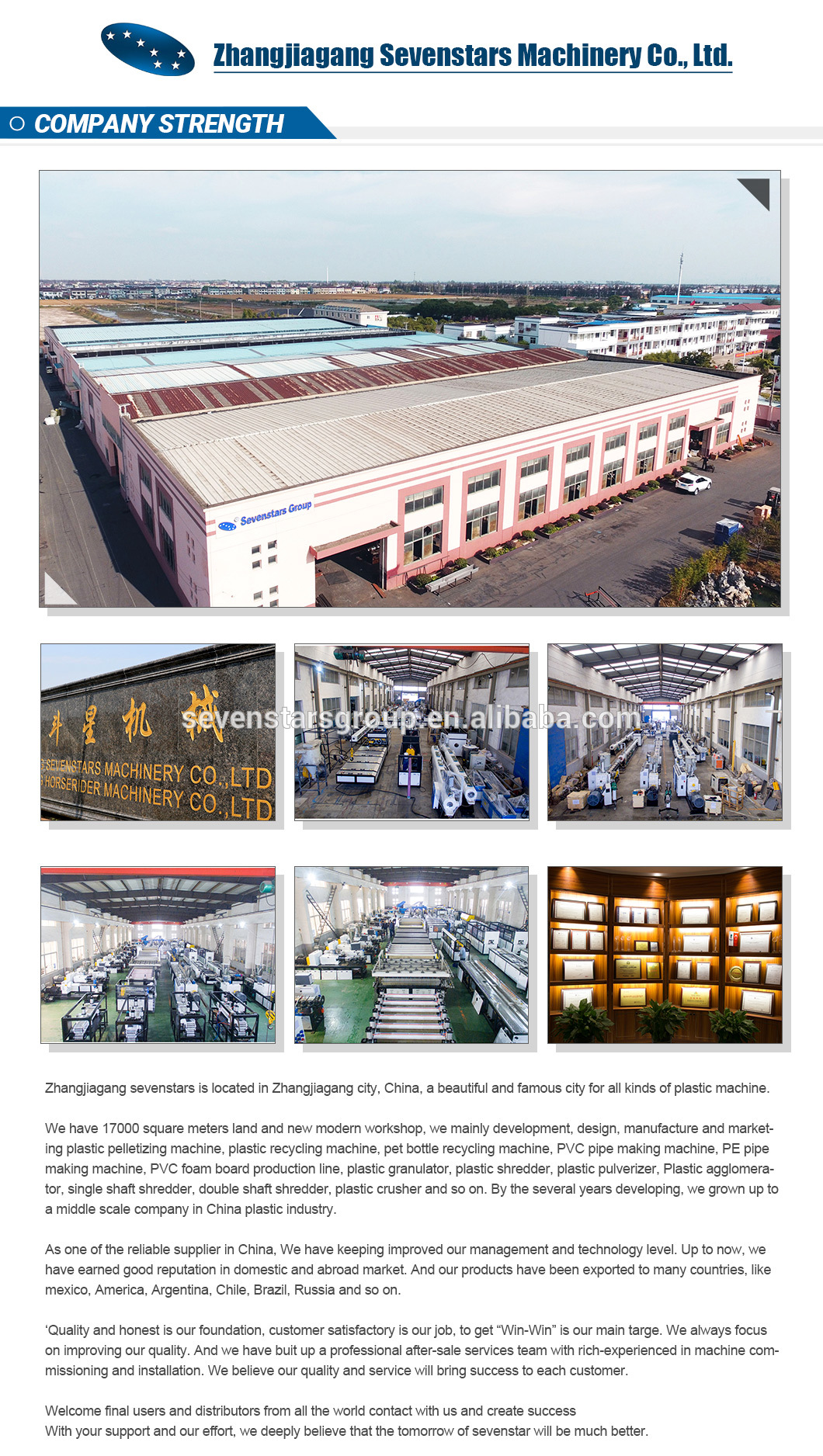

Company Profile

Certifications

Customer Photos

Contact us

FAQ

Why choose us?

1.Low cost

All the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality

We choose our material very strict.

All the material come to our factory must pass the quality test

Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.Quick delivery

The company provide just in time delivery with its streamlined supply chain.

5.Cost saving

We take strong attention to every detail in the manufacturing process.

The quality control in our factory is very strict.

All defective semi-manufactures must be treated again or reject.

All the machine must be checked out ,then delivered to our customer.

All about that pushing up the price,but get good quality machine.

What we want to do is give our customer a good quality product with stable working and long lived.

1.Low cost

All the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality

We choose our material very strict.

All the material come to our factory must pass the quality test

Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.Quick delivery

The company provide just in time delivery with its streamlined supply chain.

5.Cost saving

We take strong attention to every detail in the manufacturing process.

The quality control in our factory is very strict.

All defective semi-manufactures must be treated again or reject.

All the machine must be checked out ,then delivered to our customer.

All about that pushing up the price,but get good quality machine.

What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords