Door board extrusion machine plant door making line

-

$80000.001-2 Set/Sets

-

$40000.00≥3 Set/Sets

- Port:

- Shanghai seaport for PVC WPC door board extrusion machine plant

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 20 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,T/T |

| Port: | Shanghai seaport for PVC WPC door board extrusion machine plant |

Product Description

Product Description

Product Description

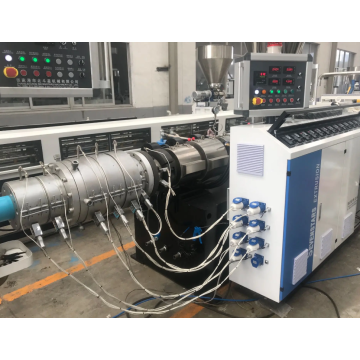

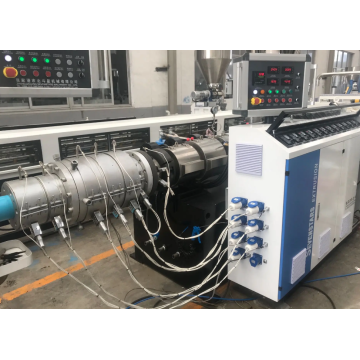

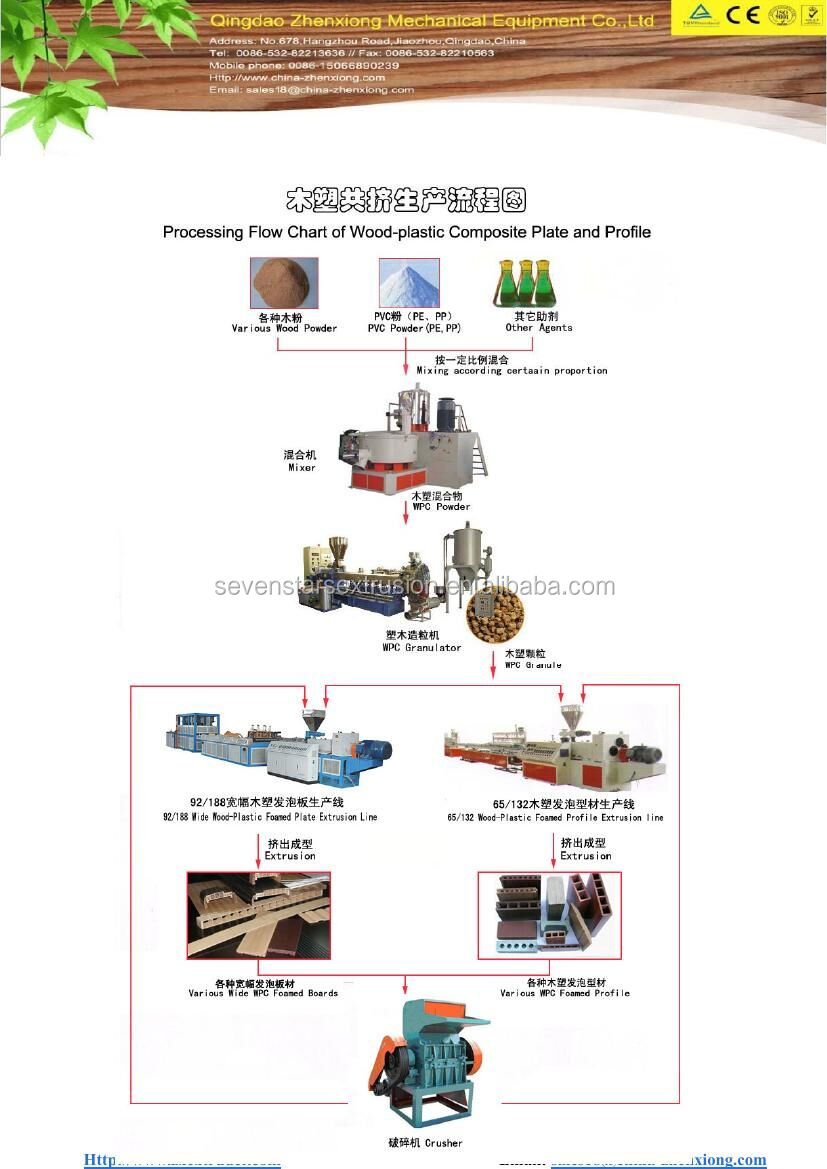

PVC WPC door board extrusion machine plant

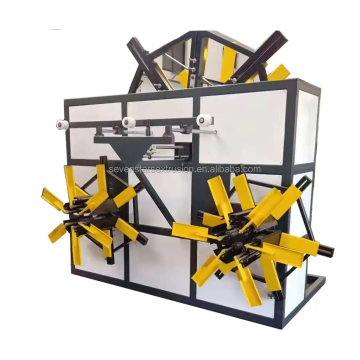

General description :This Wpc Door Board Extrusion Machine is designed according to international latest technology, mixed PVC with plant fibre symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form. The wood plastic panel out from our line has features of green environment protection, damp proof, antisepticise and not distortion, thus suitable for processing method of wood and can be recycled to reuse. It has been widely used in wide door, partition panel, construction template, base plate of container, furnish panel, etc.

PVC door board with various wall thickness and width. This line is made up of the conical twin-screw extruder, vacuum forming table, haul-offs, cutter, rickstand, etc. The extruder and the haul-offs adopt the imported AC frequency control device. The vacuum pump and the electric vehicle motor empoly the superior goods. It is additionally attached with measuring apparatus and the intensifying device. The unit is reliable and efficient production pvc panel extrusion line and pvc board extrusion line.

Specification

|

Model

|

|

SJSZ51/105

|

SJSZ65/132

|

SJSZ80/156

|

||

|

Screw dia.

|

mm

|

Φ51/Φ105

|

Φ65/Φ132

|

Φ80/Φ156

|

||

|

Screw max. rotation speed

|

r/min

|

40

|

34.7

|

38

|

||

|

Main extruder power

|

KW

|

15

|

37

|

55

|

||

|

Barrel heating power

|

KW

|

8

|

24

|

36

|

||

|

Central height

|

mm

|

1000

|

1000

|

1000

|

||

|

Main products

|

/

|

Frame, Door board, Batten

|

Frame, Door board

|

|

||

|

Screw heating and cooling

|

/

|

Conduction oil

|

|

|

||

|

Barrel heating and cooling

|

/

|

Electricity heater, Force cooling by air

|

|

|

||

Recommend Products

Contact us

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided-----------seaworthy packing

PVC WPC door board extrusion machine plant

Company Profile

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords