PVC Ceiling Extrusion Machine Line For House Decorate

-

$28000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Ningbo, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | Shanghai, Ningbo, Qingdao |

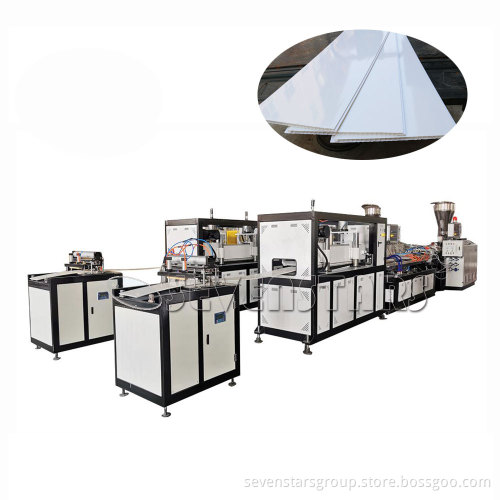

PVC Ceiling Extrusion Machine Line For House Decorate

Production flow of pvc ceilling panel production line:

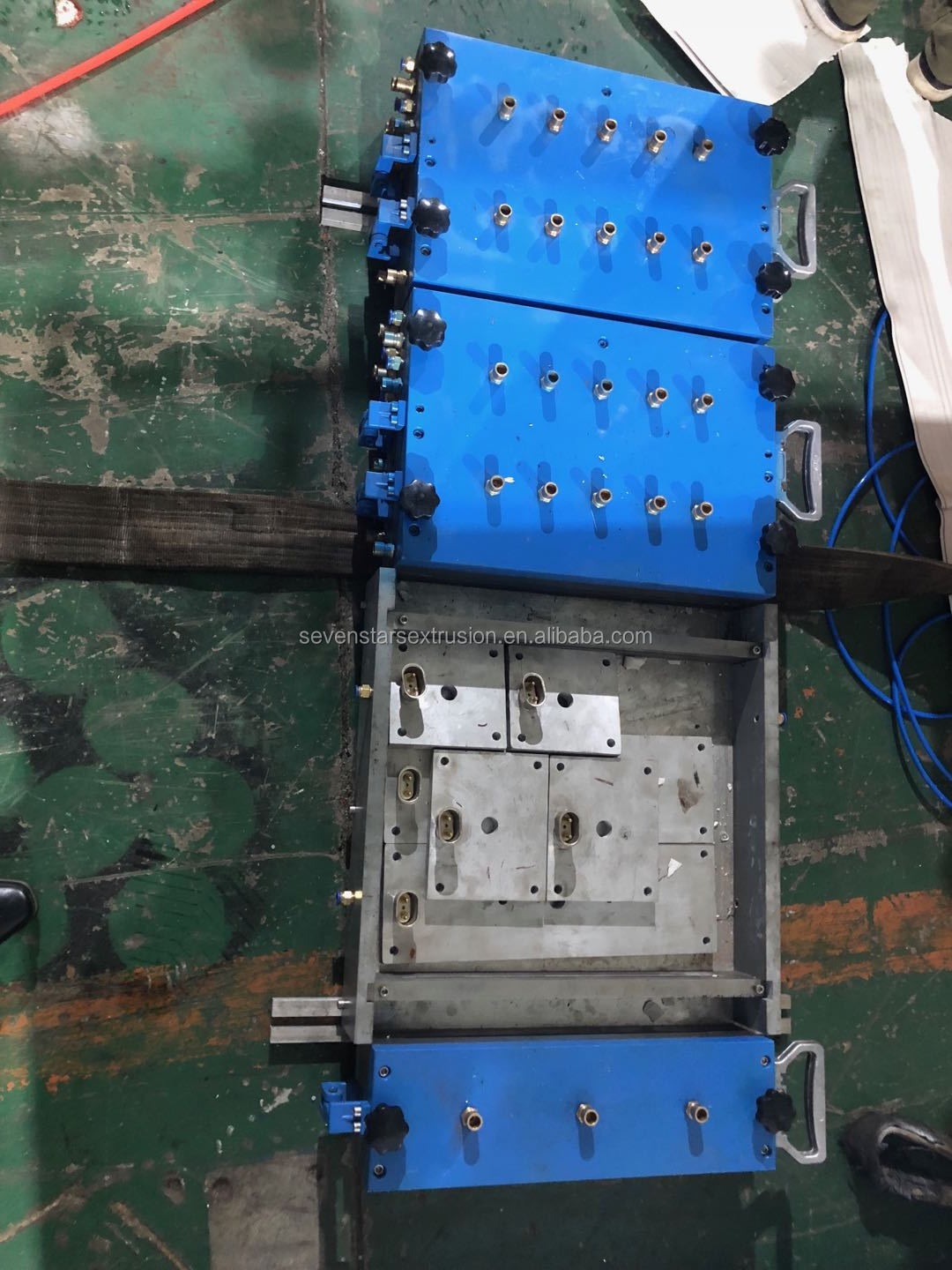

Material batching mixing→extruding→molding→vacuum calibrating and cooling→hauling→cutting→final PVC ceiling

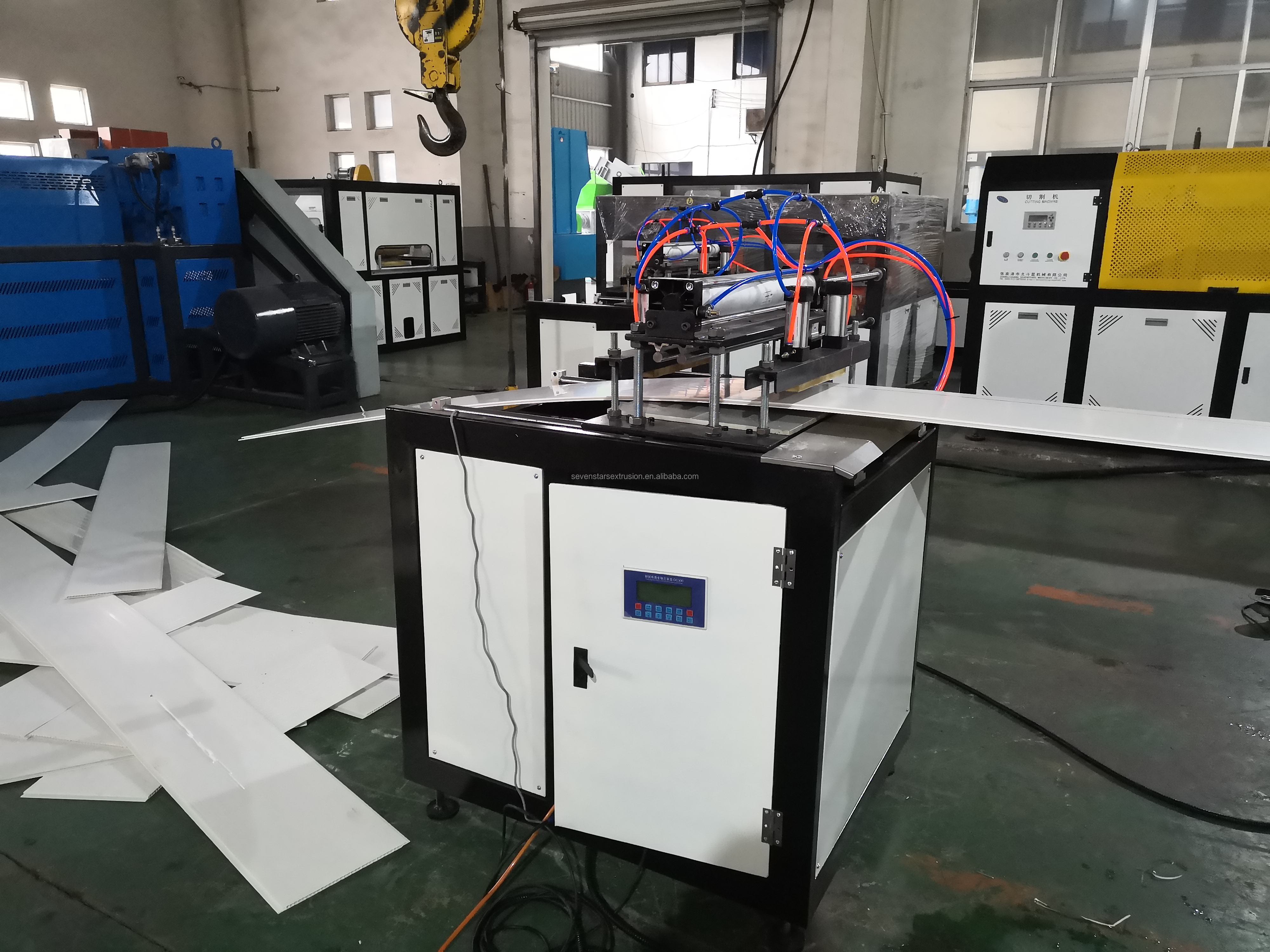

Surface treating ways:

- hot stamp printing

- two color printing

- lamination

Advantages of pvc profile extrusion:

1.100% Water proof, Moisture proof

2.Wall Panel are 100% Damp proof

3.No splitting, cracking, warping or rotting.

4.No painting or varnishing

5.Wall Panel are Light in weight

6.Consistency in quality

7.Easy to install Time and labor saving

8.High durability

9.Wall Panels are Wide range color

10.High aesthetic appeal

11.Reusable

PVC ceiling panel extrusion production line used to produce PVC ceiling wall panel with different size, such as 200mm, 250m,300mm, 400mm, 600mm and so on.

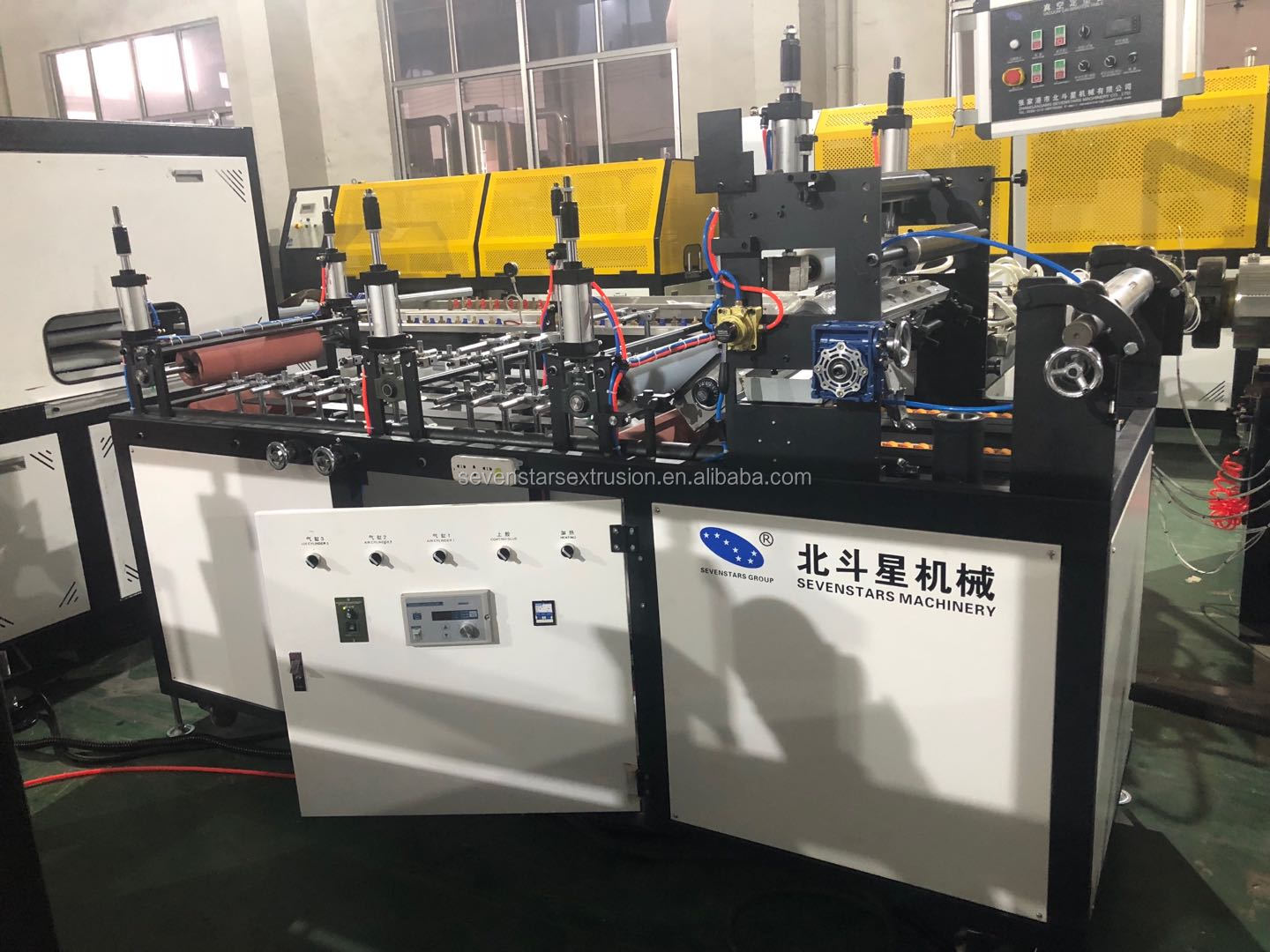

The main machines needed for pvc profile extrusion:

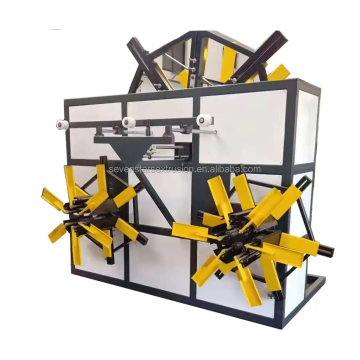

-PVC mixer

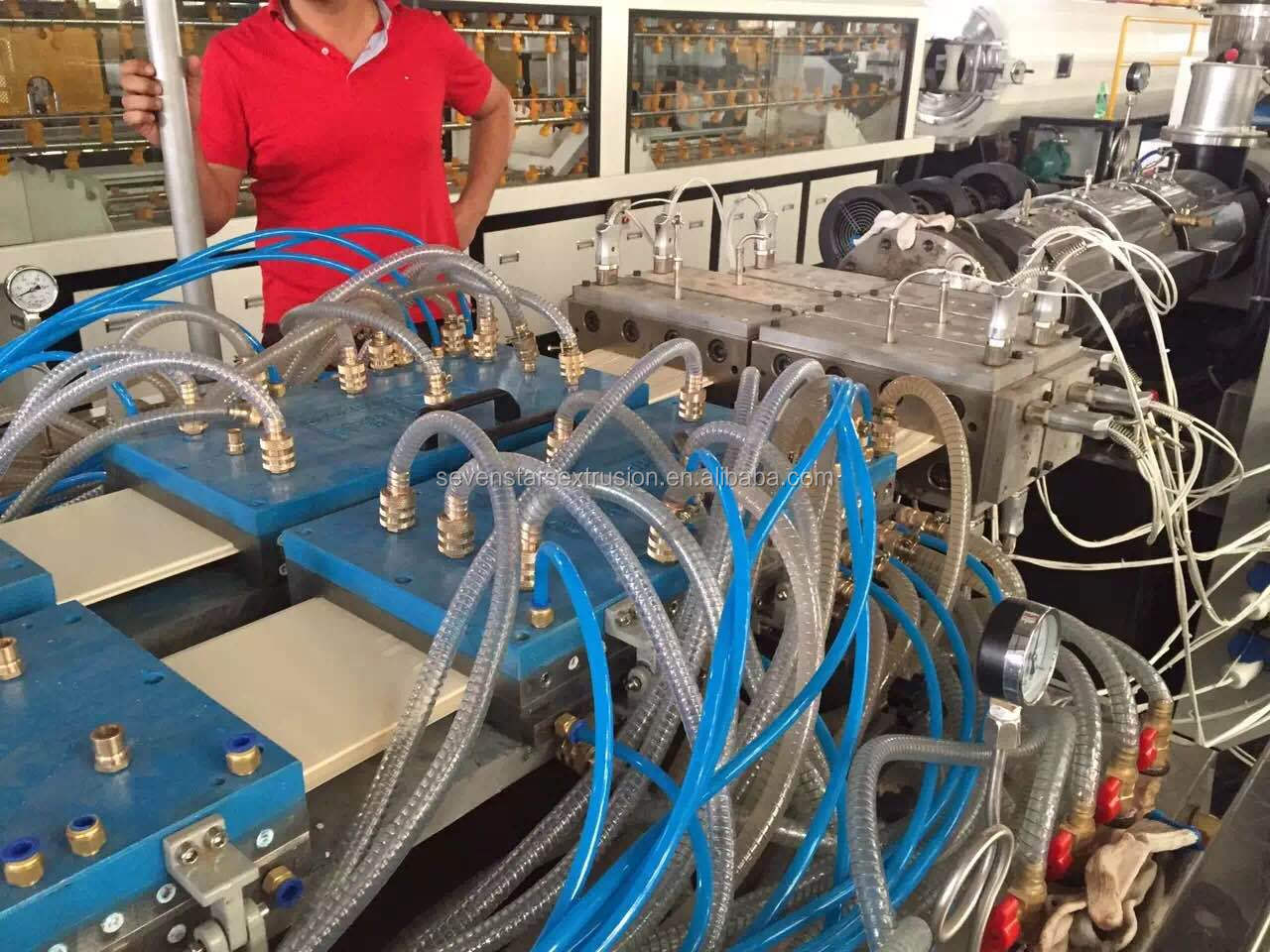

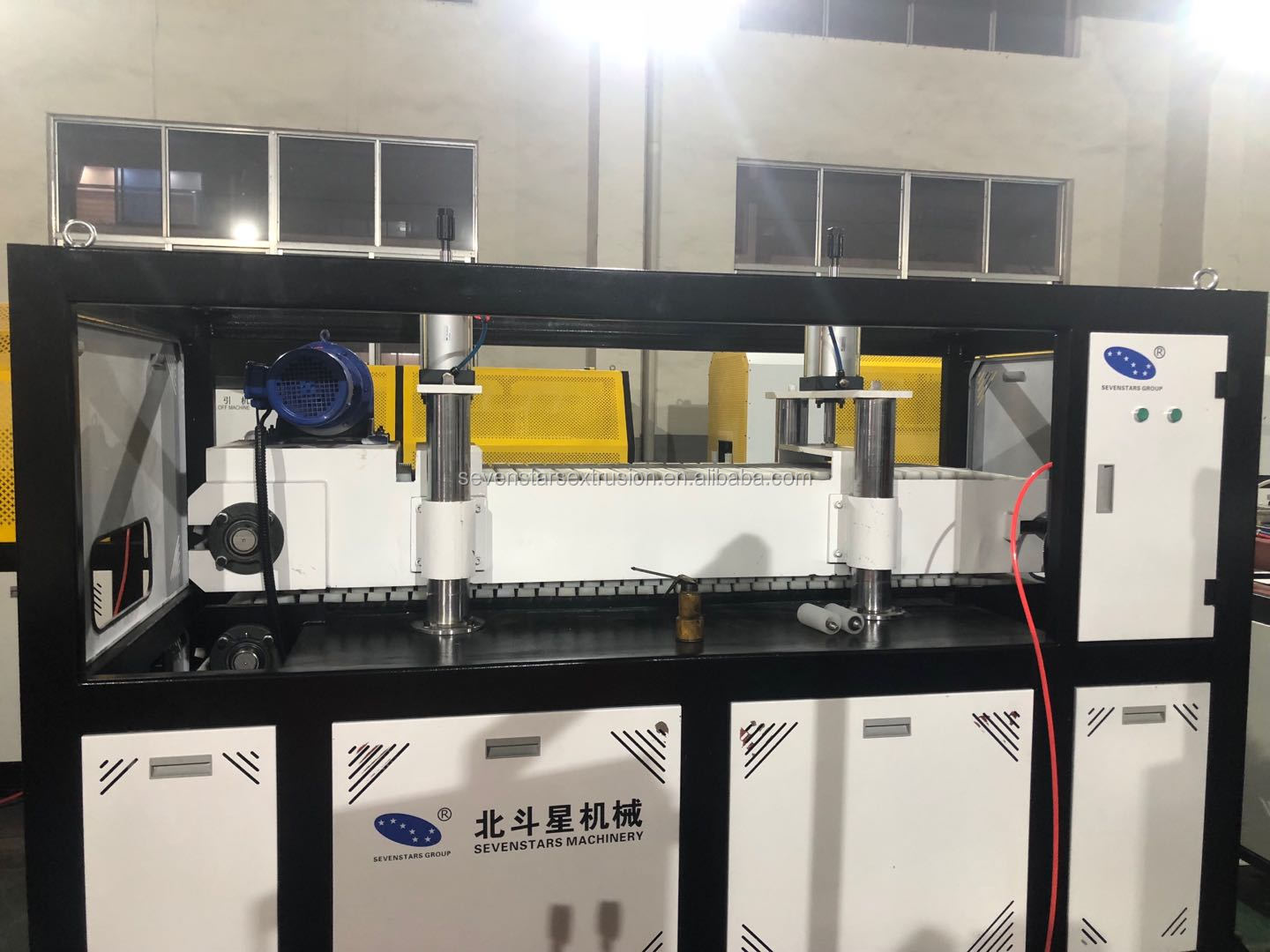

-PVC panel extrusion line (Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

- hot stamp printer or two color printing line or lamation

- PVC pipe crusher& PVC miller

- Air compressor

- Water chiller (optional)

|

Popular Model

|

YF-300

|

YF-600

|

|

|

Extruder

|

SJZZ51/105 or SJSZ55/110

|

SJSZ65/132

|

|

|

Suitable size of panel

|

160mm,200mm,250mm,300mm

|

250mm,300mm,400mm,600mm

|

|

|

Max capacity(kg/h)

|

About 100

|

About 200

|

|

|

Production line speed

|

3.5-8m/min

|

|

|

Related Keywords