Complete PVC Ceiling Wall Panel Making Machine Line

-

$20000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean |

| Port: | shanghai seaport |

Product Description

Product Description

Complete PVC Ceiling Wall Panel Making Machine Line

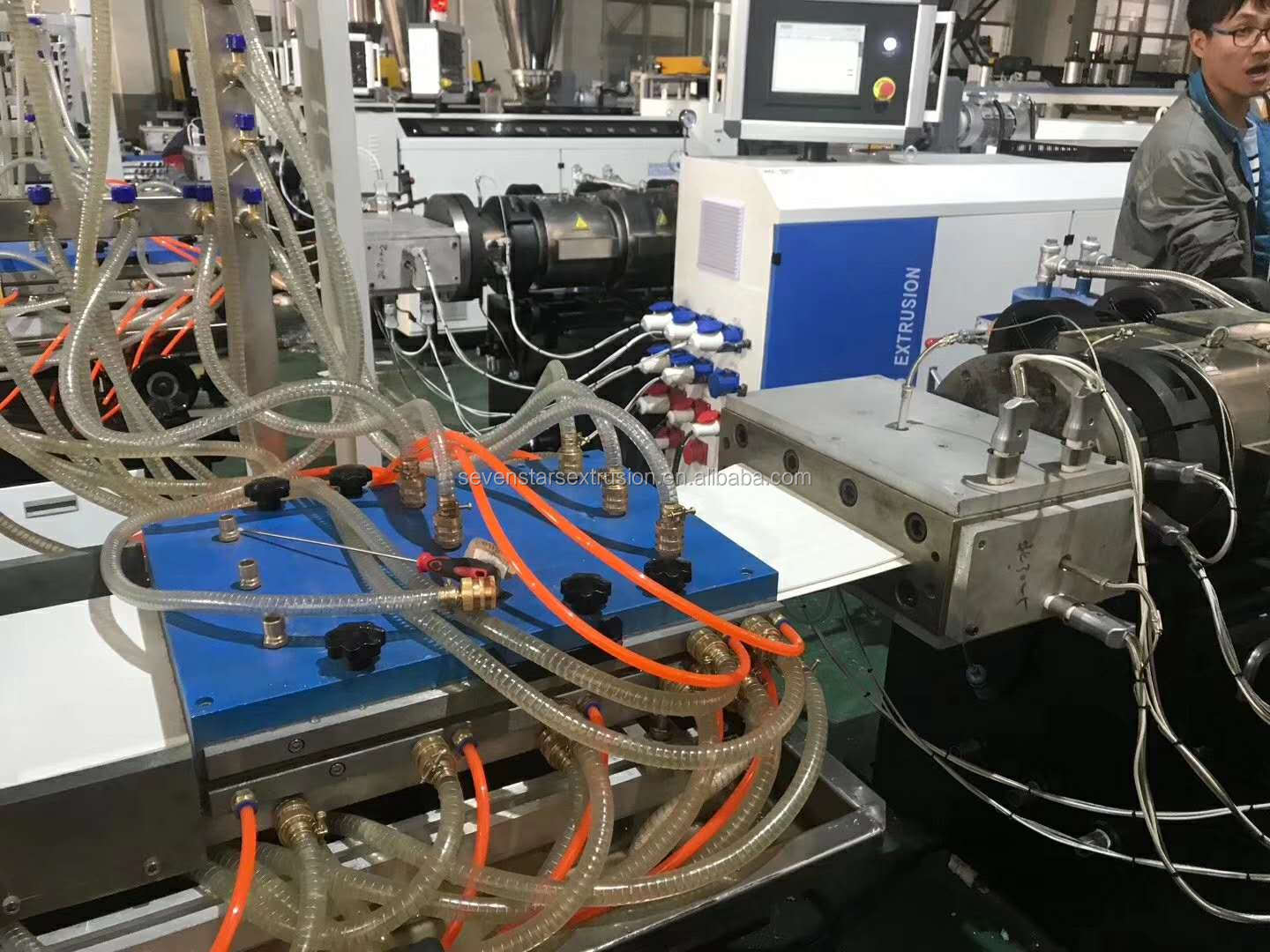

Complete pvc ceiling wall panel making machine / production line with online lamination line is used to produce PVC celing panel or PVC wall panel with width normally from 200mm to 300mm with different section shape and height. The surface of PVC ceiling panel can be treated by double by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

Products:PVC Ceiling Panel Machinery,Complete PVC Ceiling Panel Machine,PVC Ceiling Panel Making Machine Line

1.Auto loader for raw material ---1set

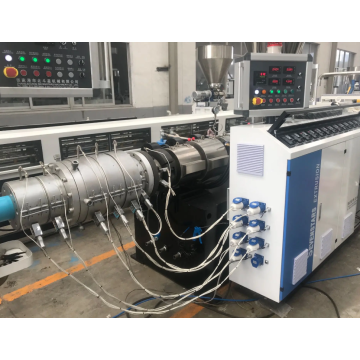

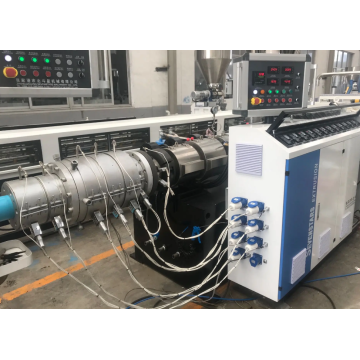

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

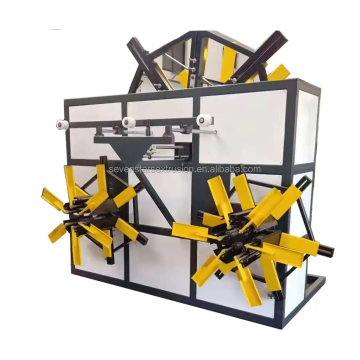

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

9.Auxilary equitment (mixer, crusher, pulverizer, color printer.etc )

Advantages:

* with Infrared tracking device, benefit for product shape control, suitable benefit for seamless edge PVC ceiling panel

* extruder flange adopts hinged type, convenient for changing filtration net, reduce time for changing net. cutter adopts rolling blade, reduce dust collection and material waste.

* speed controlled by inverter, saving power and easy to adjust speed

* extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting

* easy and convenient for operation and maintain

* low power consumption: lowest total production line consumption 25kw/hour

* economical price, suitable for large scale investment.

* extruder flange adopts hinged type, convenient for changing filtration net, reduce time for changing net. cutter adopts rolling blade, reduce dust collection and material waste.

* speed controlled by inverter, saving power and easy to adjust speed

* extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting

* easy and convenient for operation and maintain

* low power consumption: lowest total production line consumption 25kw/hour

* economical price, suitable for large scale investment.

Details Images

conical twin screw extruder

Mold

Vacuum cooling table

Hot stamping and laminating machine

Haul off machine

Cutting machine

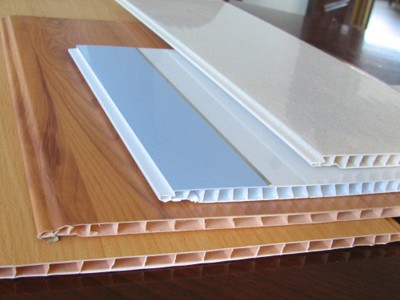

Final Product

Product Paramenters

|

Model

|

48/113

|

55/110

|

65/132

|

80/156

|

|

Applicable product width

|

160-200mm

|

200-300mm

|

400-600mm

|

500-800mm

|

|

Extruder model

|

SJSZ48/118

|

SJSZ55/110

|

SJSZ65/132

|

SJSZ80/156

|

|

Capacity (kg/hour)

|

50-150kg/h

|

60-180kg/h

|

120-300kg/h

|

180-400kg/h

|

|

Main motor power(KW)

|

15

|

30

|

37

|

55

|

Related Keywords

Related Keywords