Wood Plastic Composited Making Machine Production Line

$40000.00 - $60000.00/Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,D/P,D/A,T/T,MoneyGram |

| Transportation: | Ocean |

| Port: | shanghai seaport |

Product Description

Product Description

Product Description

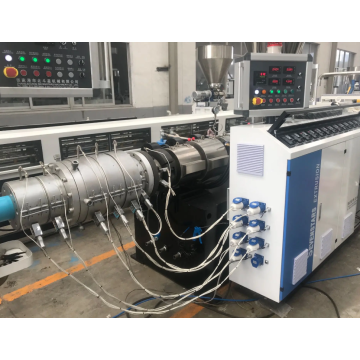

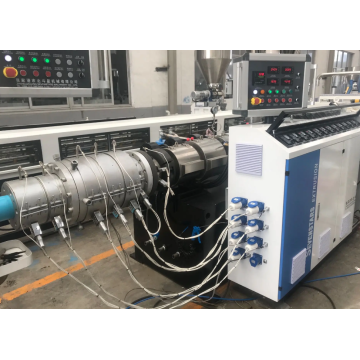

Wood Plastic Composited Making Machine Production Line

Products:Wood Plastic Composited Making,Composited Making Machine Production Line,Wood Plastic Composited Making Machine

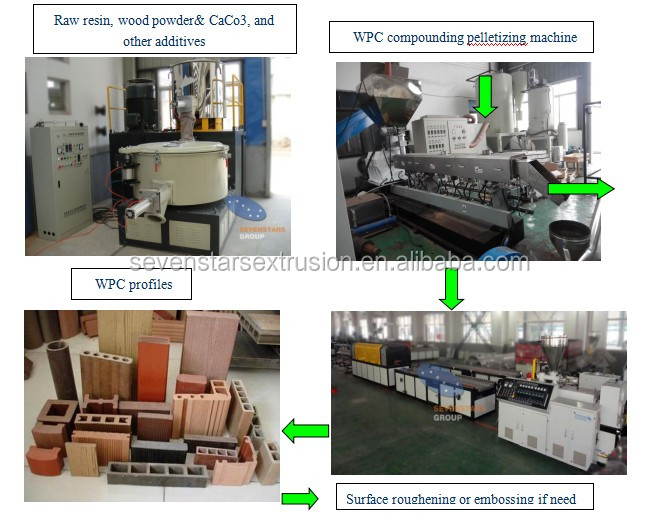

Product description:

PVC /WPC profile extrusion machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding ofoutdoor wall, facility of outside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

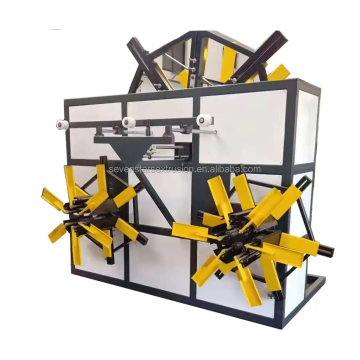

Application of wood plastic profile extrusion line:

Profiles for the building industry

windows ,door frame and board,rolling shutters ,gutters ,fencing ,ceiling,deck,floor Profiles for furnishing,furniture edge

bands,coatings.

Technical profile for industry:

1.Conical twin-screw extruder is perfect, with PVC powder or granular material.

2.Mould designed by different kinds of profile customer required.

3.supply formula guide and staple raw material purchase.

Technical data:

|

Model

|

Max width

(mm)

|

Extruder model

|

Max output(kg/h)

|

motor power(kw)

|

|

BDX108

|

108

|

SJZ51/105

|

100

|

18.5

|

|

BDX180

|

180

|

SJZ51/105 or SJZ55/110

|

100/150

|

18.5/22

|

|

BDX240

|

240

|

SJZ65/132

|

250

|

37

|

|

BDX300

|

300

|

SJZ65/132

|

250

|

37

|

|

BDX400

|

400

|

SJZ80/156

|

350

|

55

|

|

BDX500

|

500

|

SJZ80/156

|

350

|

55

|

|

BDX600

|

600

|

SJZ80/156

|

400

|

75

|

Details Images

Related Keywords

Related Keywords