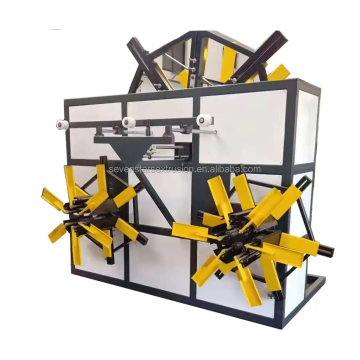

PET bottle crushing washing recycling machine line

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 300-5000kg/h |

| Supply Ability: | 100sets per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE ISO |

| HS Code: | 84778000 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Model of PET bottle crushing washing recycling machine

|

Model

|

Capacity(kg/h)

|

Length(M)

|

working way

|

|

PET300

|

300

|

25

|

Automatic

|

|

PET500

|

500

|

25

|

Automatic

|

|

PET1000

|

1000

|

35

|

Automatic

|

|

PET1500

|

1500

|

35

|

Automatic

|

|

PET2000

|

2000

|

40

|

Automatic

|

|

PET3000

|

3000

|

50

|

Automatic

|

|

PET4000

|

4000

|

65

|

Automatic

|

|

PET5000

|

5000

|

80

|

Automatic

|

|

PET6000

|

6000

|

90

|

Automatic

|

Description of PET bottle crushing washing recycling machine line and plastic pelletizer machine

Raw material & formulation: Post-consumer PET bottles for pet recycling.

Warehouse/Workshop:About 1000 square meters with height 7 meters

Water supply:Consumption: 6-7ton/h(but it can recycled use)

Note : 1) water consumption of the line depend on the installed components ,the contamination of the imput material and the installed water filter and water treatment system

2) to reduce the water consumption ,we recommend to install a water treatment plant , by using press filter ,the load of waste water could be further minimized , the buyer should provide water tank (we recommend ground tank)with level indicator and water pumps and valves

3) Main machine parts: bale opener, label remover,crusher,fricition washer,hot washer,washer tank,dewater machine,label separator,hot air pipe dryer,color sorter..

4) after washing and drying,the scraps can be make gruanules by plastic pelletizer machine and plastic granulator.

Picture of recycle plastic machine

Related Keywords