water PET bottle recycling machine line

-

$50000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300-3000KG/H |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

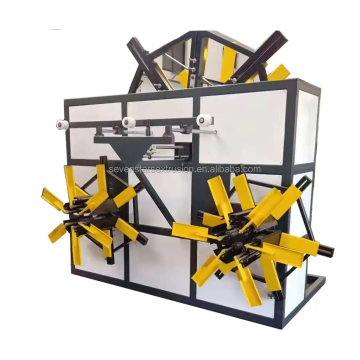

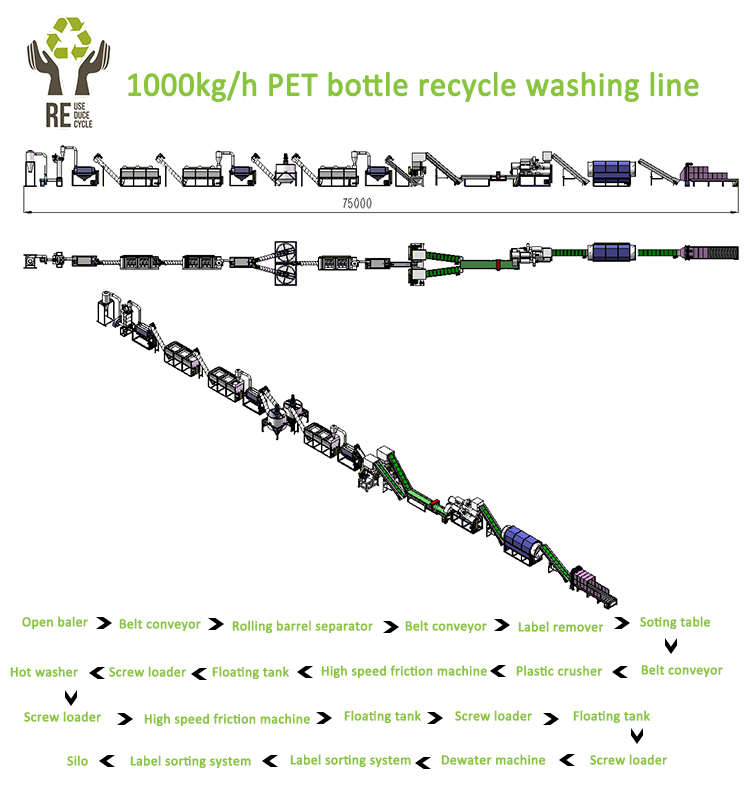

According the PET recycling business, we’d like to recommend our standard PET bottle washing line with an output capacity of 300kg/hr. This plastic recycling machine line is composed of garbage separation (automatic and manual separation), crushing, continuous washing and dewatering & drying parts. Please check the below information:

1.1 Material characteristics

The material to be treated is PET bottles with contamination of:

● Labels

● Residues of original bottle content

● Metal, dust or sand accumulated during transportation or permanence in air

● PE plastic caps (PVC bottles, Aluminum caps are not accepted)

The materials can be in bales or loose, the operators should open the bale before introducing material into the line.

Finished product: clean PET flakes

1.2 Basic Infrastructure (Provided by customer)

b. Electricity network: 380V/50Hz/3Phase

c.Wire/cables: wires/cables from customer’s general control cabinet to the main control cabinet for PET washing line; all electrical cable from the main control cabinet to each machine.

d. Water supply: main water pipeline supply and water pipes to machines

e. Heat supply: A steam boiler and steel pipes covered with temperature-preservation layer to hot washer

f. Means for lifting the machines when unloading and position

In addition, Zhangjiagang Sevenstars Machienry has Plastic Extruder,pvc pipe making machine,Plastic Granulator,Plastic Auxiliary Machinery and other plastic machine.

Raw material

& formulation

Post-consumer PET bottles

Final use of PET

Flake

PET fiber use and

some other use

Final product

& Output capacity

output Bottle

flakes : 1000kg/h

Description of

final product

1. Moisture: less than 1%

2. PET flake size: 14mm

3.PE/PE and Paper and other impurity <total 100PPM

4.metal<10ppm

5. Ph-value : Neutral

6.colorful pet flake (has to be sort out by hand)

7.melting point : 245-252

8.PVC content <50ppm

9.other polymers<20ppm

10.Inert material<5ppm

11.Bulk

density: 0.3G/ C CM3

12.dust

fraction <0.2%

Related Keywords