Big diameter HDPE PE pipe extruder machine line from Sevenstars Machinery

-

$41800.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | shanghai seaport |

Product Description

Product Description

General description

Plastic PE PPr pipe making extrusion machine line :

PE PPr pipe extrusion making machine extruder line can be used in PE PPr large diameter gas and water pipe which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on.So, this PE PPr pipe extrusion line is a preferred gas and water pipe for ductwork system between city and its suburb.Large diameter HDPE LDPE PE pipes start to play very important role in the city water and gas supply systems.

Characteristics:

1.Capacity: single screw extruder, suitable to process PE resin with high capacity, max 1000kg/h

2.Diameter: from 16 to 800mm

3.Extruder adopts big L/D and multi mixing structure, which is more suitable for the PE PP PPR low temperature extrusion

production.

4.Specially-designed spiral moulds for PE PP PPR pipes with marking line, with inside oil controlling temperature system

5.Beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, unique multi-section vacuum system ensures the stable sizing and cooling for pipes with marking line; special spray cooling system improves the cooling efficiency ; special water position, water temperature system make the machine more intelligent.

6.Hauling-off unit adopts particular pedrail structure, which is easy and convenient for operation; pedrail clamping uses

mechanical and pneumatic combining system, which is more reliable.

7.Cutting system adopts saw blades and planetary cutting means; sumping uses hydraulic system , which ensures the smooth cross section; equipped with dust-collecting unit, which ensures the clean working environment.

Flow chart of PE PPr pipe extrusion making machine line

PE granules Raw material + additive → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker

PE PPr pipe extrusion making machine extruder line can be used in PE PPr large diameter gas and water pipe which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on.So, this PE PPr pipe extrusion line is a preferred gas and water pipe for ductwork system between city and its suburb.Large diameter HDPE LDPE PE pipes start to play very important role in the city water and gas supply systems.

Characteristics:

1.Capacity: single screw extruder, suitable to process PE resin with high capacity, max 1000kg/h

2.Diameter: from 16 to 800mm

3.Extruder adopts big L/D and multi mixing structure, which is more suitable for the PE PP PPR low temperature extrusion

production.

4.Specially-designed spiral moulds for PE PP PPR pipes with marking line, with inside oil controlling temperature system

5.Beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, unique multi-section vacuum system ensures the stable sizing and cooling for pipes with marking line; special spray cooling system improves the cooling efficiency ; special water position, water temperature system make the machine more intelligent.

6.Hauling-off unit adopts particular pedrail structure, which is easy and convenient for operation; pedrail clamping uses

mechanical and pneumatic combining system, which is more reliable.

7.Cutting system adopts saw blades and planetary cutting means; sumping uses hydraulic system , which ensures the smooth cross section; equipped with dust-collecting unit, which ensures the clean working environment.

Flow chart of PE PPr pipe extrusion making machine line

PE granules Raw material + additive → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker

Product Description

Specification

|

Pipe Range

|

16-63mm

|

20-110mm

|

75-160mm

|

90-250mm

|

110-315mm

|

160-450mm

|

315-630mm

|

500-800mm

|

630-1200mm

|

|

Extruder

|

¢45mm

|

¢60mm

|

¢75mm

|

¢75mm

|

¢90mm

|

¢90mm

|

¢120mm

|

¢150mm

|

¢200mm

|

|

Extruder Power

|

AC30KW

|

DC75KW

|

DC110KW

|

DC110KW

|

DC160KW

|

DC160KW

|

DC280KW

|

DC335KW

|

DC400KW

|

|

Extrusion Capacity

|

60-100kg

|

100-150kg

|

250-300kg

|

250-300kg

|

350-400kg

|

350-400kg

|

650-700kg

|

850-900kg

|

1100-1500kg

|

|

Max. Speed

|

10m/min

|

6m/min

|

6m/min

|

6m/min

|

3m/min

|

1.2m/min

|

0.9m/min

|

0.7m/min

|

0.5m/min

|

Detailed photo

Single screw extruder

Extrusion mold

Calibrate vacuum cooling tank

Water spring tank

Haul off machine

Cutting machine

Product packaging

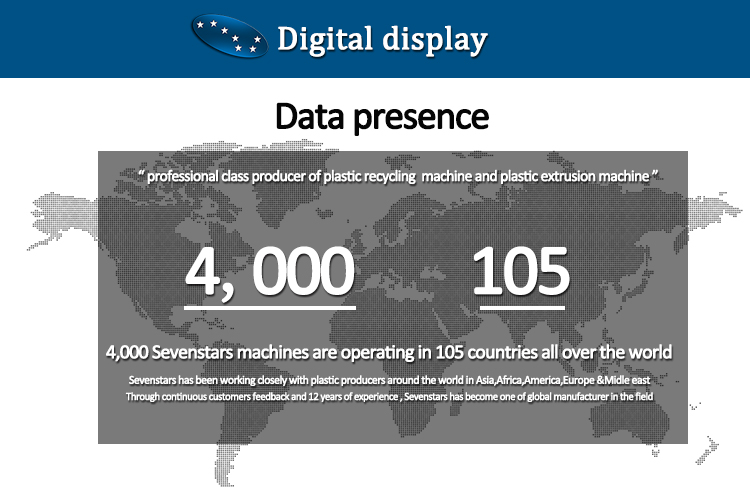

Company Profile

Zhangjiagang Sevenstars Machinery Co.,Ltd. was founded in 2006. it is an enterprise specialized in producing plastic machinery.it lies to the south of the middle and lower reches of Yangtze River.It is located in the National civilization and hygienic city-zhangjiagang , Surrounded by the economic belt of Suzhou,Wuxi,Changzhou,Nanjing and Shanghai.Both land and river transports are rather convenient.We sell our products to Europe middle,Africa and Asia,etc country and region.Our products enjoy a high reputation home and abroad.

Our clients

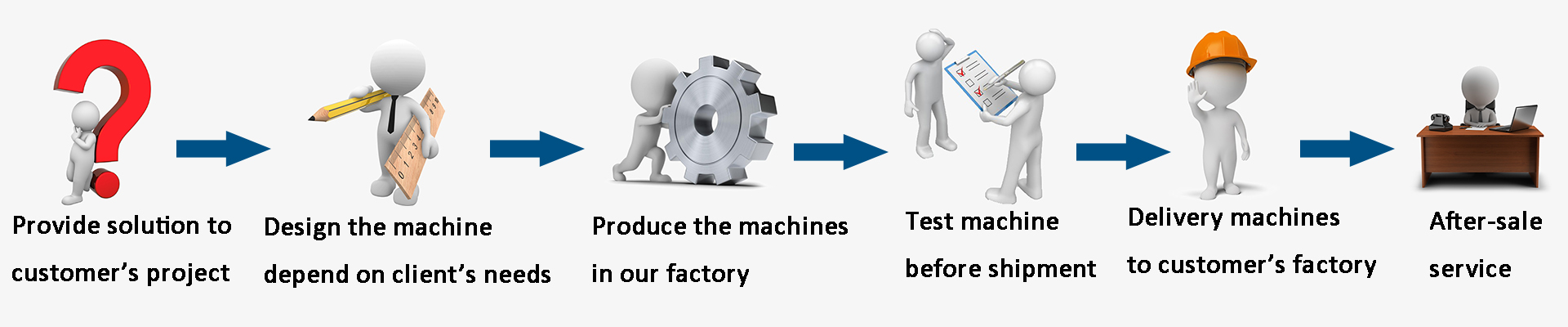

FAQ

1.How about the quality about this machine?

Answer: yes,my friend,please rest assured,we have nearly 10 years experience for this machine.quality is no problem.

2.How about the output about this machine?is the data real?

Answer: my friend,we have tested that machine many times,then get this data,it is real and can meet your need.

3.Wether you deliver in time?

Answer: sure,once we receive your payment, then delivery immediately.

4.What about your after service?

Answer: we can send our engineers to you factory and offer long term technical guidance.

Answer: yes,my friend,please rest assured,we have nearly 10 years experience for this machine.quality is no problem.

2.How about the output about this machine?is the data real?

Answer: my friend,we have tested that machine many times,then get this data,it is real and can meet your need.

3.Wether you deliver in time?

Answer: sure,once we receive your payment, then delivery immediately.

4.What about your after service?

Answer: we can send our engineers to you factory and offer long term technical guidance.

Related Keywords

Related Keywords