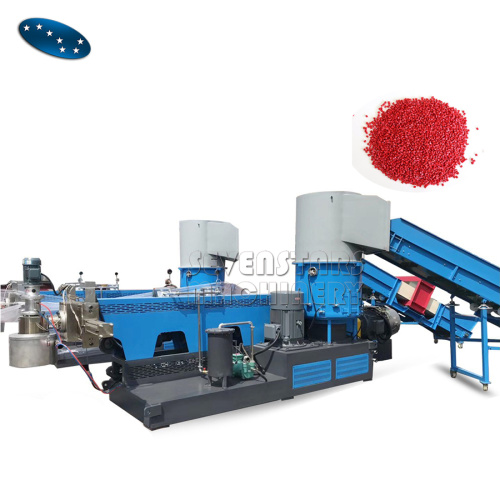

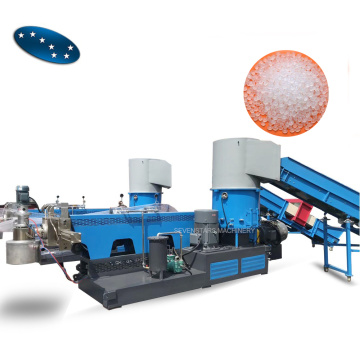

waste plastic pp pe film bags pelletizing machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 30 sets/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE ISO |

| HS Code: | 84772010 |

| Transportation: | Ocean |

| Port: | Shanghai |

PELLETIZING MACHINE LINE

Sevenstar's high efficiency, one-step plastic recycling machine compactor is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. This cutter integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a productive rate.

In addition to in-house (post-industrial) film waste, the system is also able to process washed flakes, scraps and regrind (pre-crushed rigid plastic waste from injection and extrusion). This compactor plastic recycling machine is highly recommended for packaging film producers of commercial bags, garbage bags, agricultural films, food packaging, shrink and stretch films, as well as producers in the woven industry of PP woven bags, jumbo bags, tapes and yarns. Other types of material such as PS sheet, PE and PS foam, PE net, EVA, PP mixed with PU are also applicable on this compactor plastic recycling machine.

PE PP Film Bags Pelletizing Machine

PE/PP FILM COMPACTING TYPE PELLETIZING LINE

SJ series film recycling pelletizer production line is the special equipment for the film recycling and pelletizing . With compacting machine ,it could pre-compact the thin material into the small granule,making the automatic feeding material easier,and it efficiency improves the production.Cylinder type hydraulic changer with vacuum gas exhausting enables the non-stop changing filter and no leaking material.Pelletizing by die-face-cut improves the pelletizing quality.

|

Model |

Screw Diameter (mm) |

Rotary Speed (rpm) |

Main motor (Kw) |

Compacting Machine (Kw) |

Output (kg/h) |

|

SJ85-33 |

85 |

10-120 |

55 |

37 |

150-180 |

|

SJ100-33 |

100 |

10-120 |

90 |

55 |

250-300 |

|

SJ130-33 |

130 |

10-120 |

132 |

75 |

300-400 |

|

SJ160-33 |

160 |

10-120 |

160 |

90 |

500-600 |

|

SJ180-33 |

180 |

10-120 |

250 |

132 |

800-1000 |

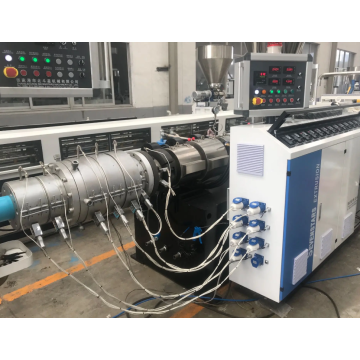

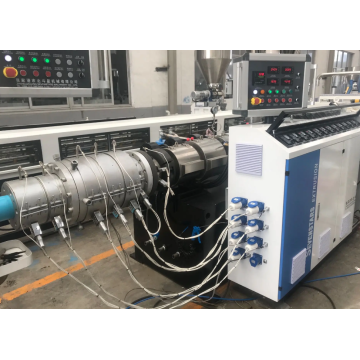

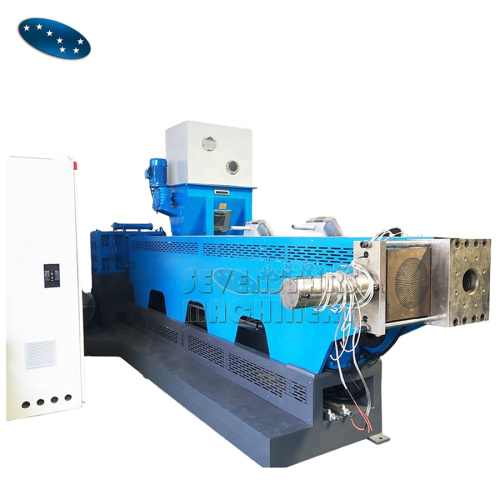

SJ double stage side force feeder pelletizing line

SJ series double stage pelletizing line is mainly designed for processing PE,PP rigid flake or waste film flake. The advantage of the double stage pelletizing line is better melting and the material is more clean after two filtering from screen changers.It is an ideal machine for the kinds of little bit dirty material. For screw L/D varies according to the material condition,for example,rigid material or film flake.

|

Model |

Screw Diameter |

L/D |

Main motor |

Output |

Cutting method |

|

SJ120/120 |

120 |

25 |

55kw |

150-200kg/h |

Die face cutting or strand cutting |

|

120 |

10 |

30kw |

|||

|

SJ140/140 |

140 |

25 |

75kw or 90kw |

250-350kg/h |

|

|

140 |

10 |

37kw |

|||

|

SJ160/160 |

160 |

25 |

160kw |

450-600kg/h |

|

|

160 |

10 |

45kw |

|||

|

Note |

The capacity is based on the raw material.The output for rigid flake and film flake are different,as well as the material.We offer solution based on the client’s actual requirements. |

||||

Related Keywords