8mm twin wall PC hollow sheet machine Pc Hollow 20mm Triple-layer making machine Greenhouse Plastic Sheet extrusion machine

-

$150000.001-2 Set/Sets

-

$120000.003-4 Set/Sets

-

$90000.00≥5 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Quarter |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | shanghai seaport |

Product Description

Product Description

Product Description

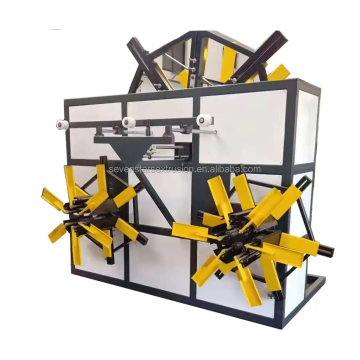

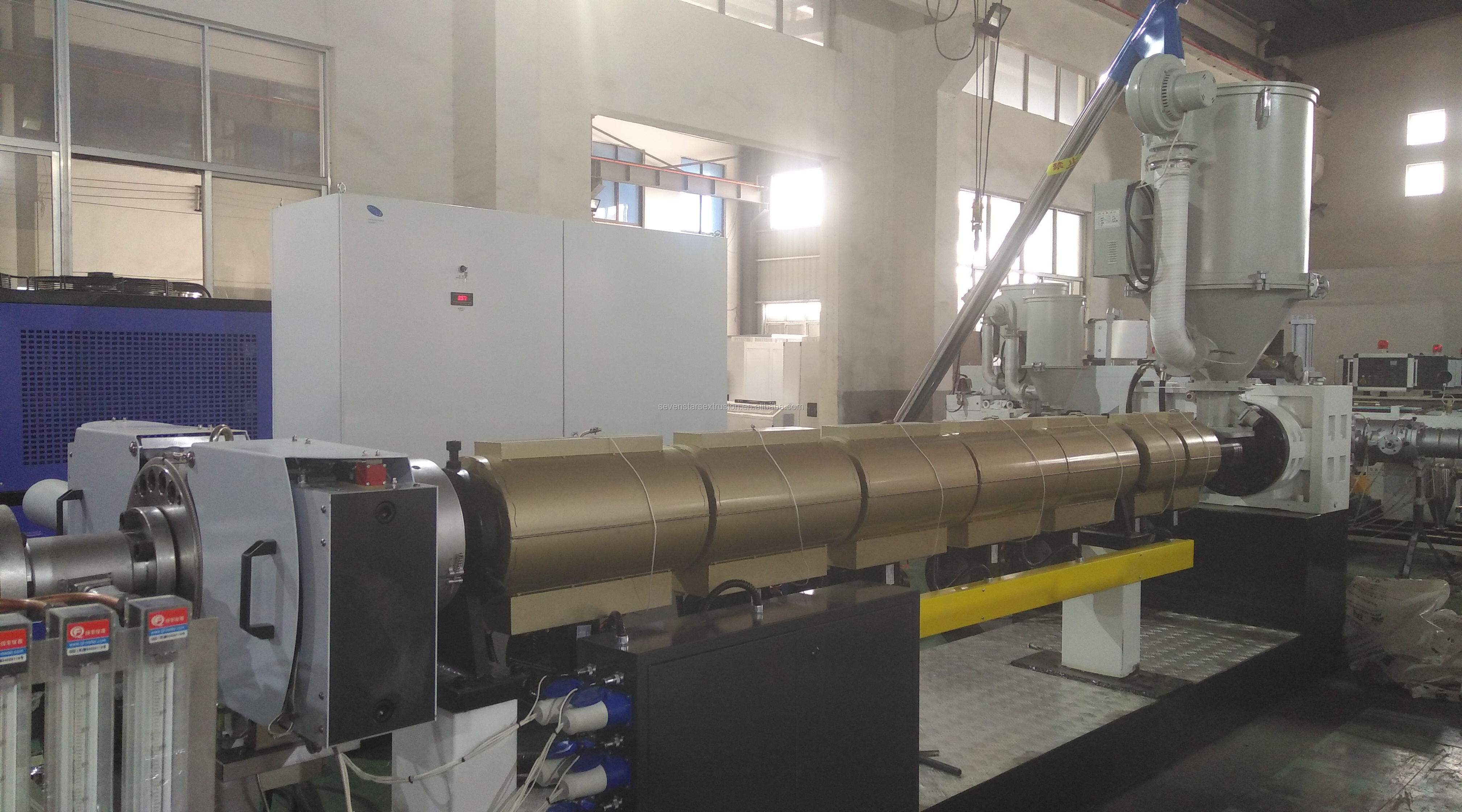

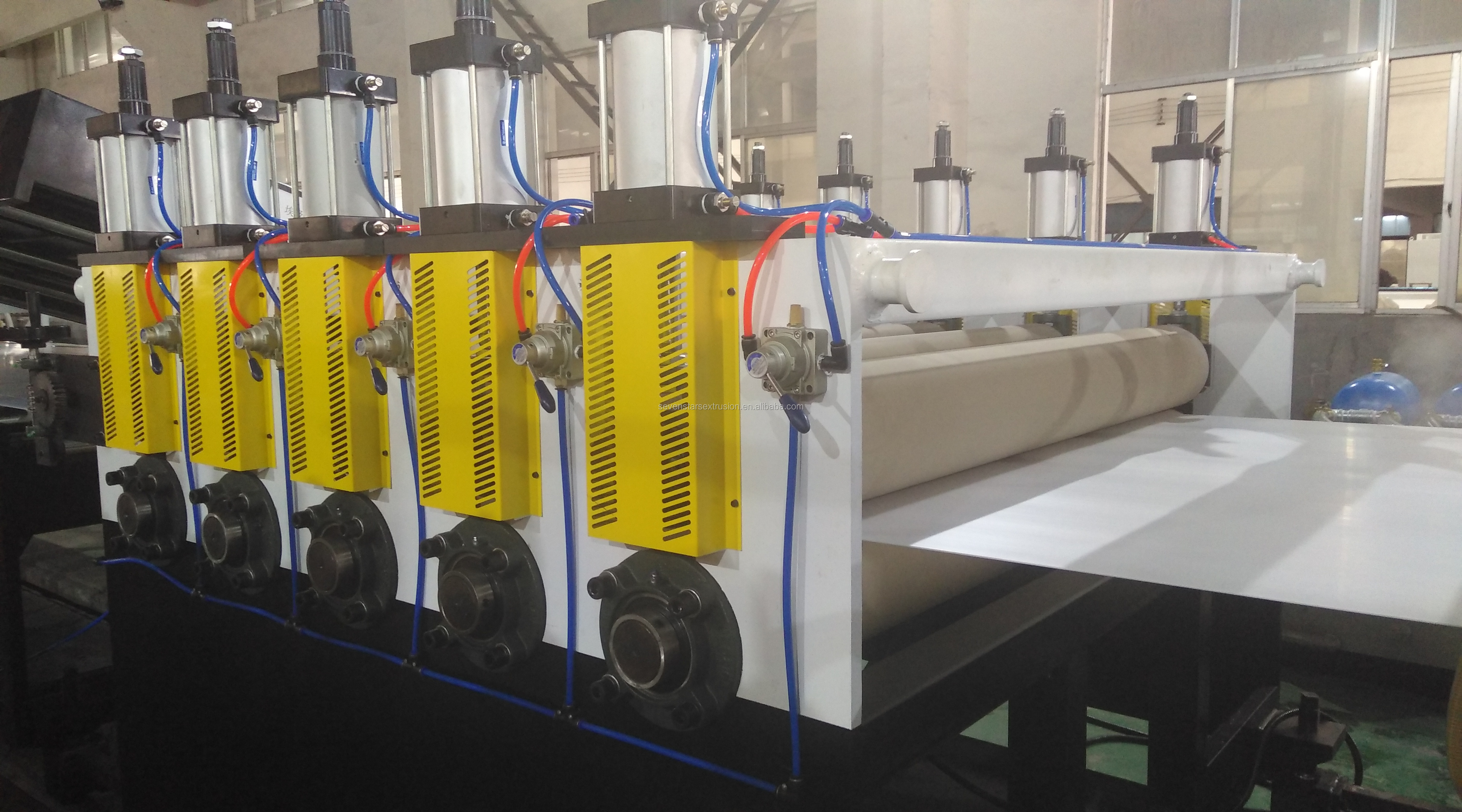

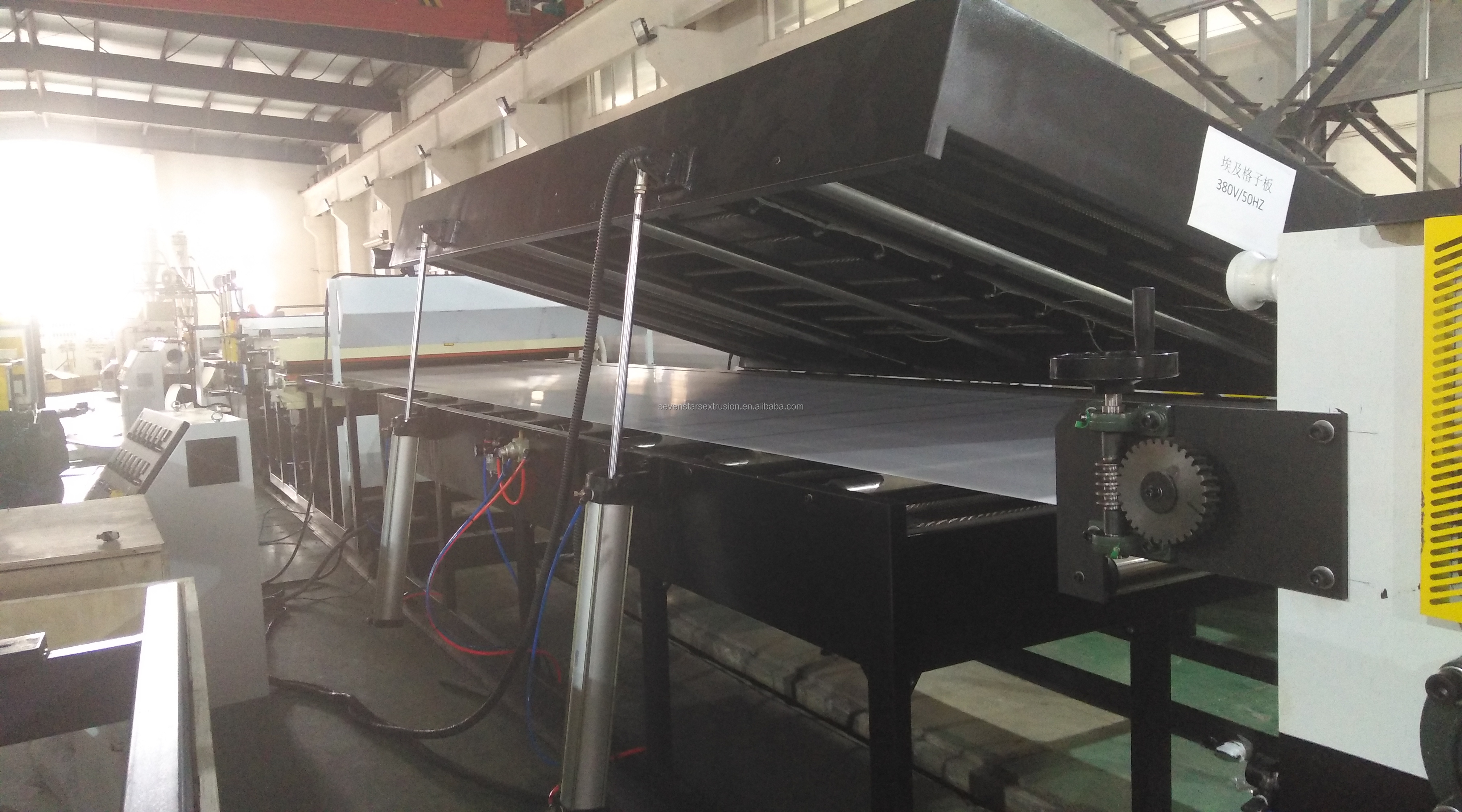

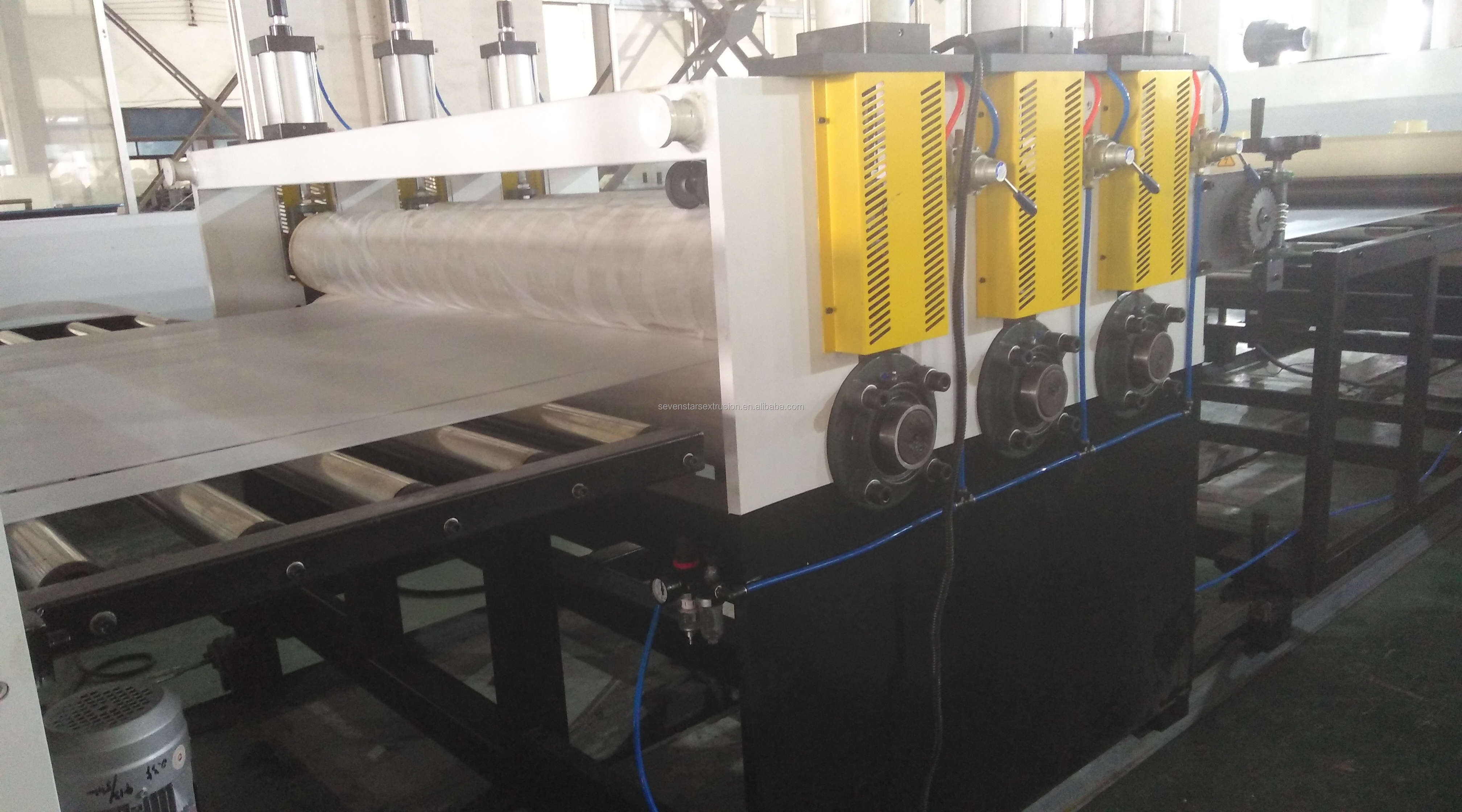

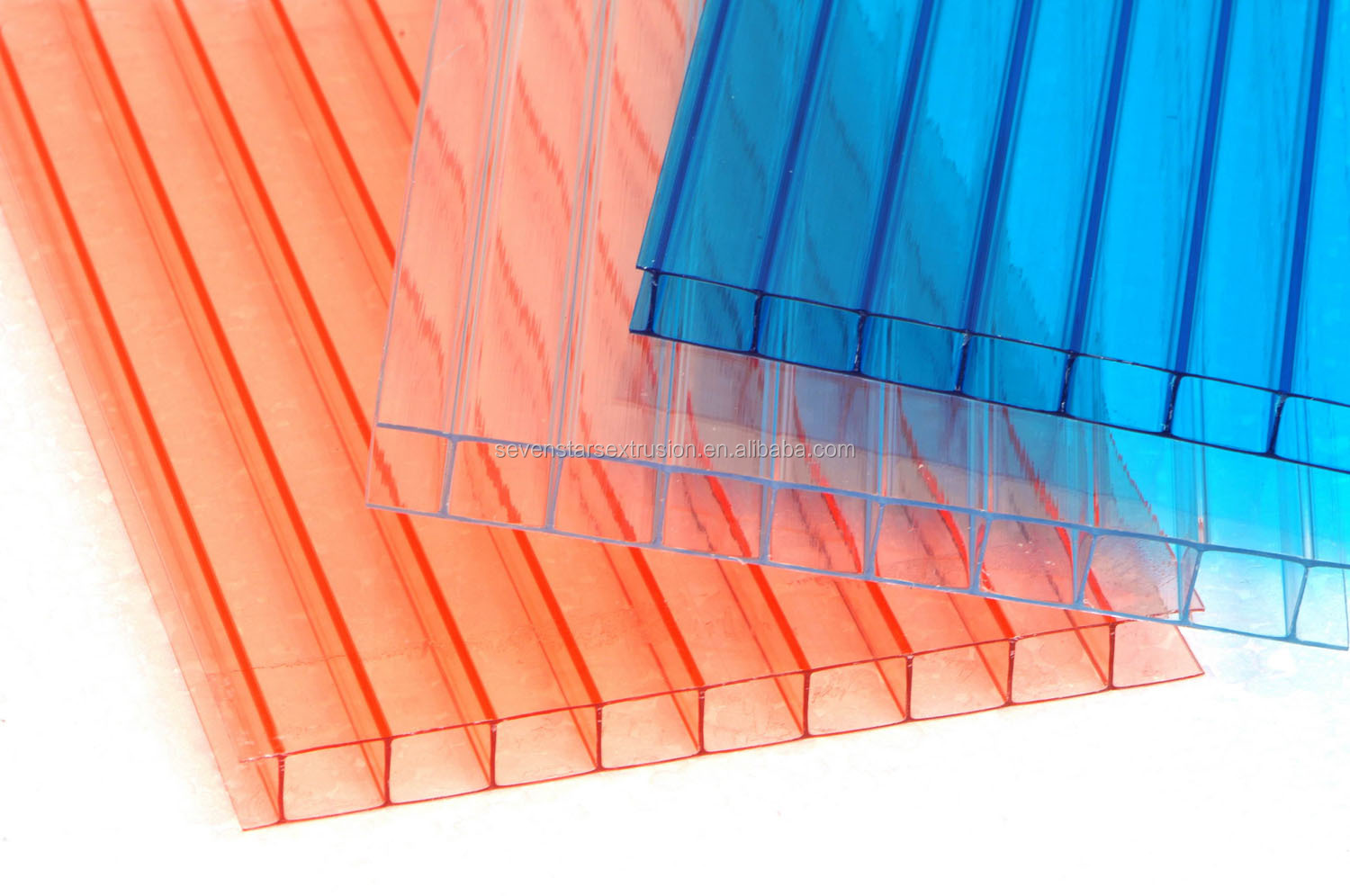

8mm twin wall PC hollow sheet machine Pc Hollow 20mm Triple-layer making machine Greenhouse Plastic Sheet extrusion machine

The company's research and development of the leading product is "complete sets of hollow lattice production line and mold", according to the thickness of the product, width, structure, shape, the use of different plastic raw materials have different categories:

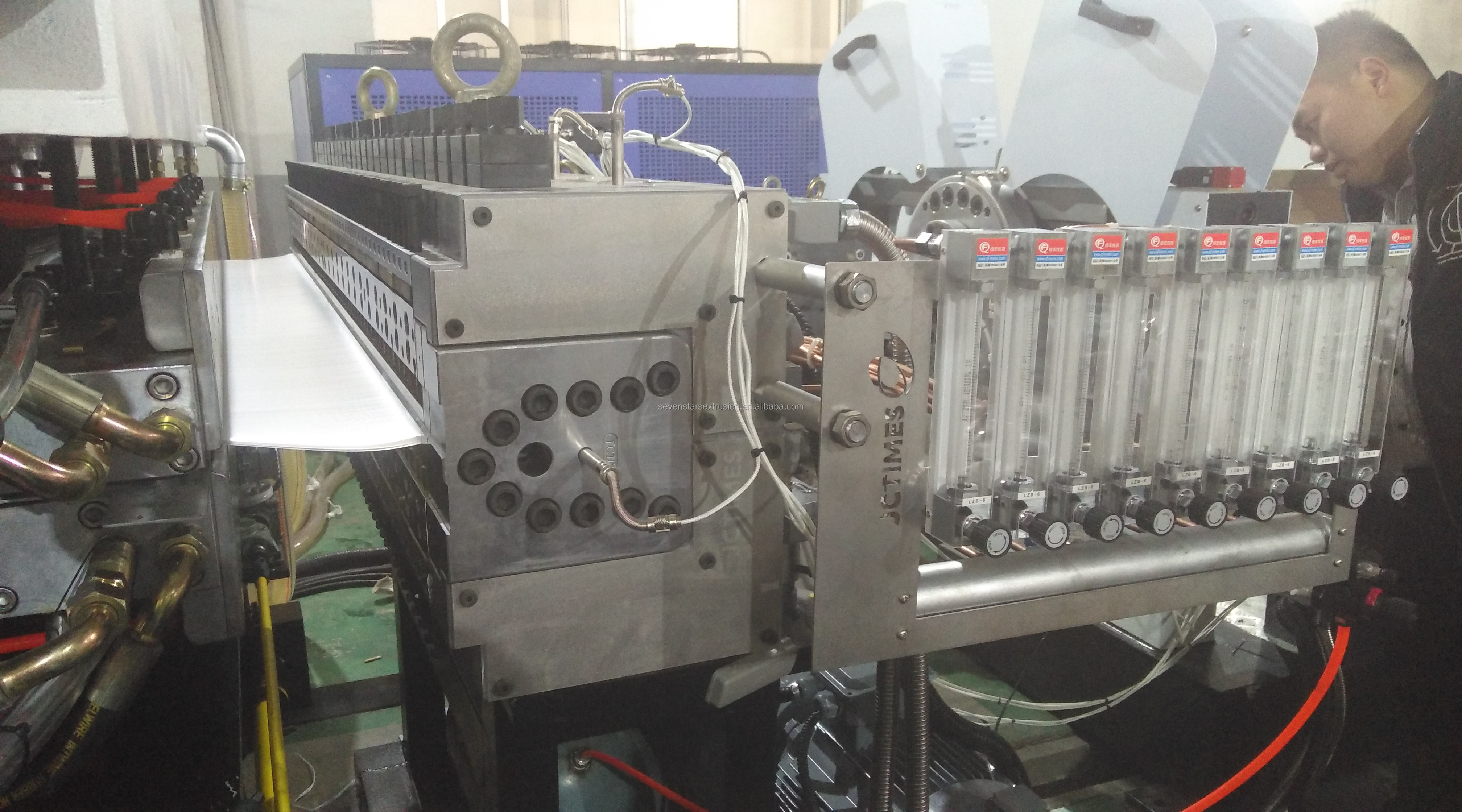

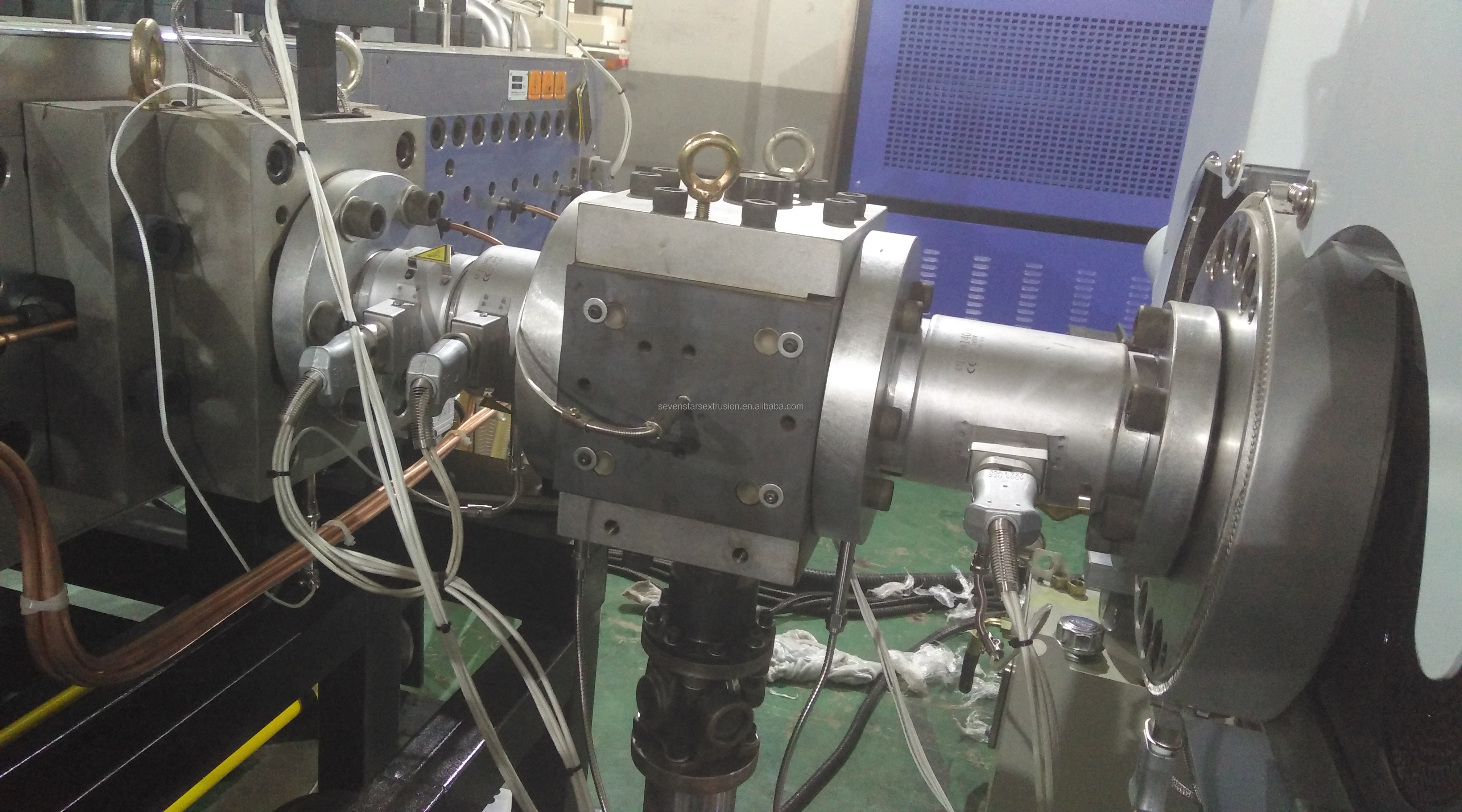

1. According to product width: can be divided into 1400mm, 1800mm, 2100mm, 2300mm unit

2. According to product thickness: can be divided into 2-6mm, 6-12mm, 12-18mm unit

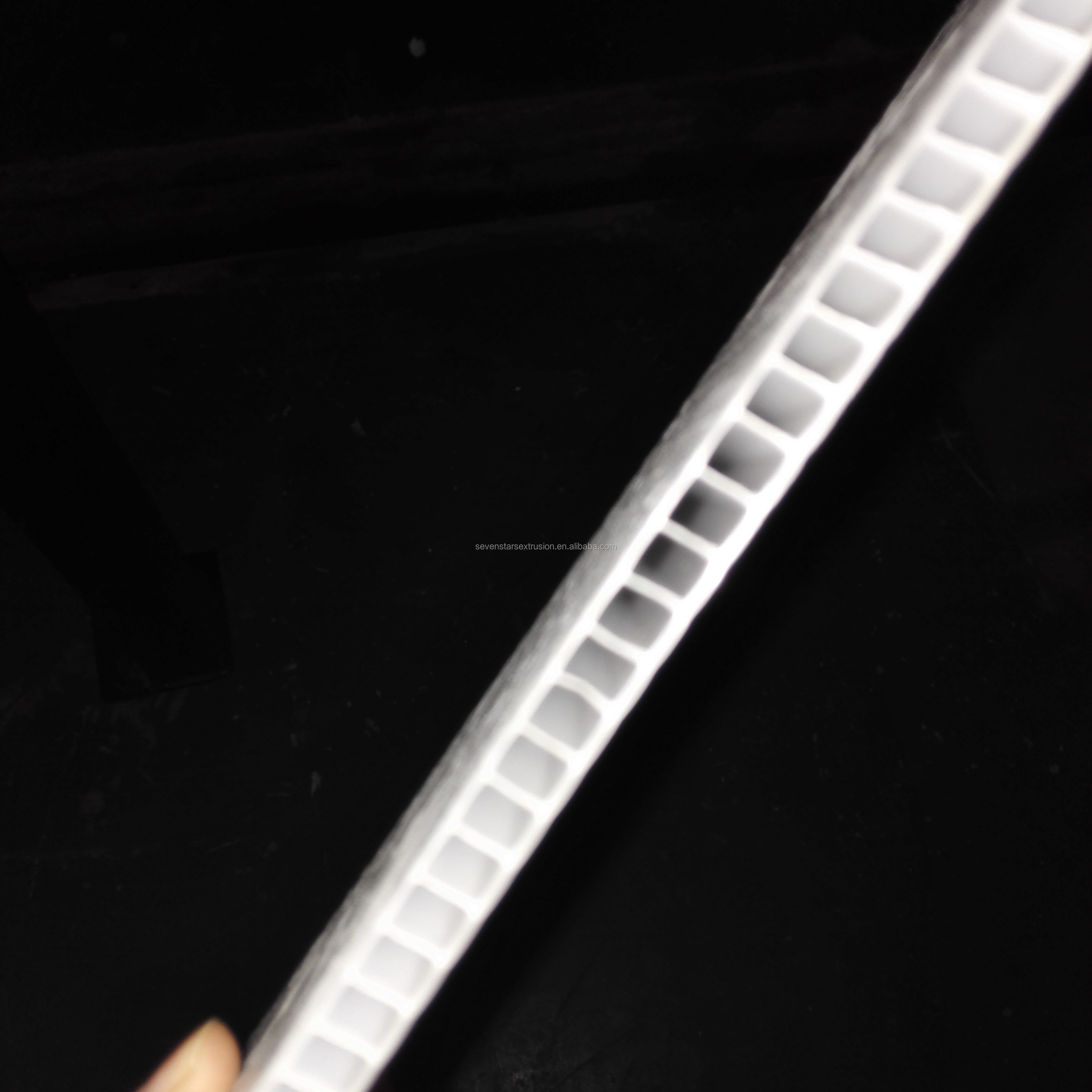

3. According to the product structure: Can be divided into double wall, three wall, four wall,

4. According to product shape: can be divided into ordinary I type, S type, V type, X type, meter type

5. According to the use of plastic raw materials products: can be divided into PP, PE, PC

PP hollow sheet application

The PP hollow grid board can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet, etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing. It is widely used in such fields as the electron, household electrical appliances, packaging, machinery, postal, food, medicine, pesticide and advertisement decoration, etc.

PC hollow sheet application

PC Hollow sheet is widely used as sun proof ceilings of office building, hall, market, stadium, recreation center and public facilities; weather shed of bus station, summer house, and corridor of lounge hall; Safe sun-proof ceilings of airport and factories, velarium of modernized agriculture, livestock breeding industry and indoor swimming pools; noise

barrier on high way and elevated road in cities, advertisement billboard, lighting box and exhibition decoration; partition wall between office and living room, and between bathroom and toilet.

Specification

Model of 8mm twin wall PC hollow sheet machine Pc Hollow 20mm Triple-layer making machine Greenhouse Plastic Sheet extrusion machine

|

Extruder model

|

Φ100

|

Φ120

|

|

Product width

|

1300/1500mm

|

2100mm

|

|

Product thickness

|

2-12mm

|

2-12mm

|

|

Motor power

|

110kw

|

132kw

|

|

Capacity

|

250-300kg/h

|

400-450kg/h

|

Recommend Products

Recommended by seller

Contact us

Packing & Delivery

seaworthy packing with bubble film and strengthen film

Company Profile

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords