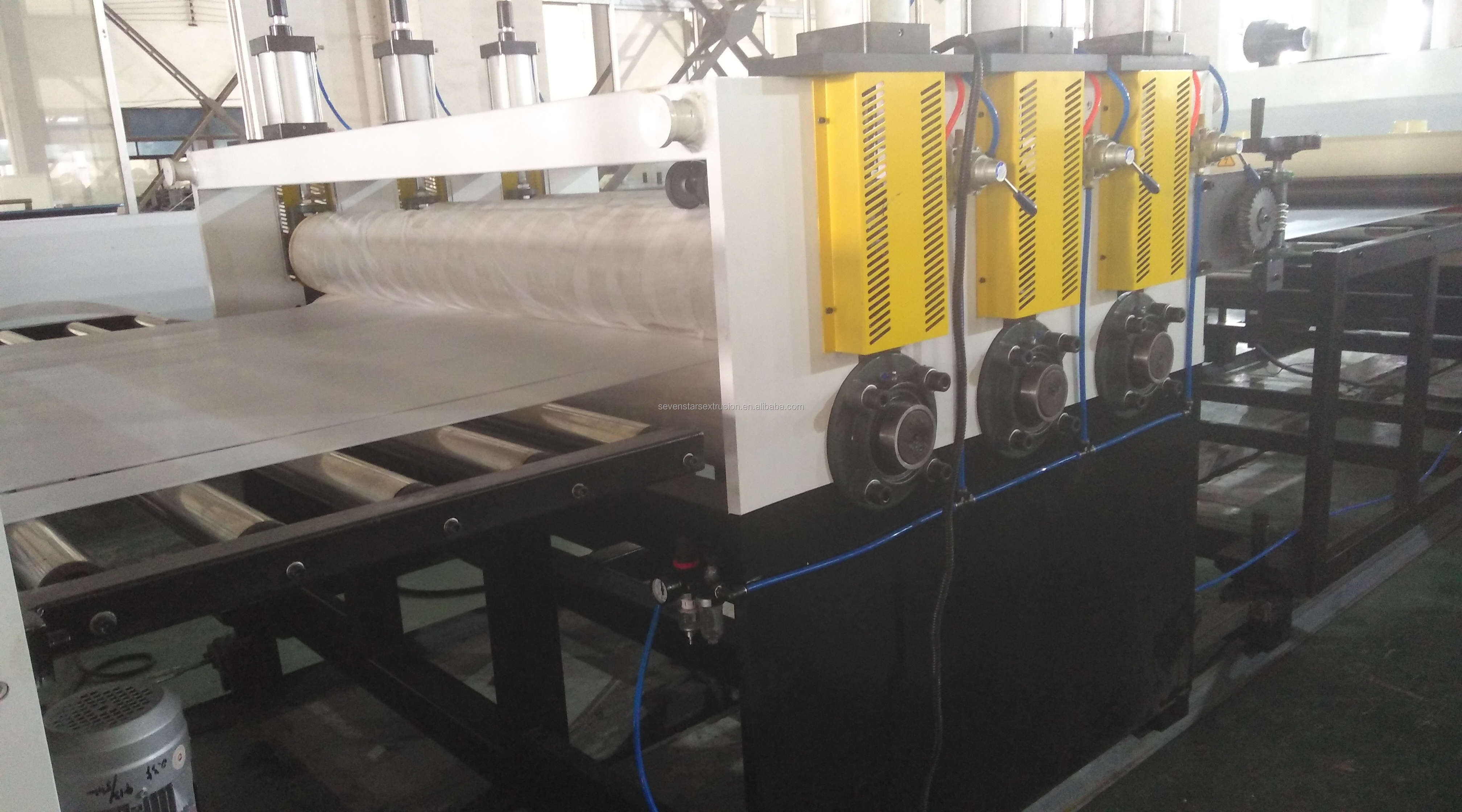

Fluted Plastic Sheet Extrusion Machine PP Construction Template Making Line PC Solid Sheet Extruder

-

$150000.001-2 Set/Sets

-

$120000.003-4 Set/Sets

-

$100000.00≥5 Set/Sets

- Port:

- shanghai seaport

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 15 Set/Sets per Quarter |

|---|---|

| Payment Type: | L/C,T/T |

| Port: | shanghai seaport |

Fluted Plastic Sheet Extrusion Machine PP Construction Template Making Line PC Solid Sheet Extruder

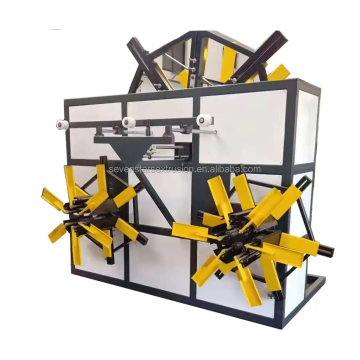

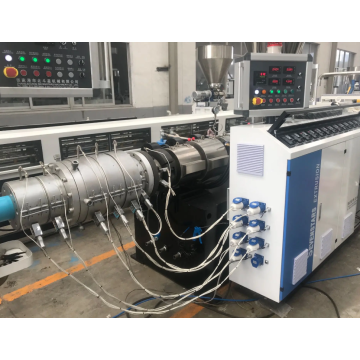

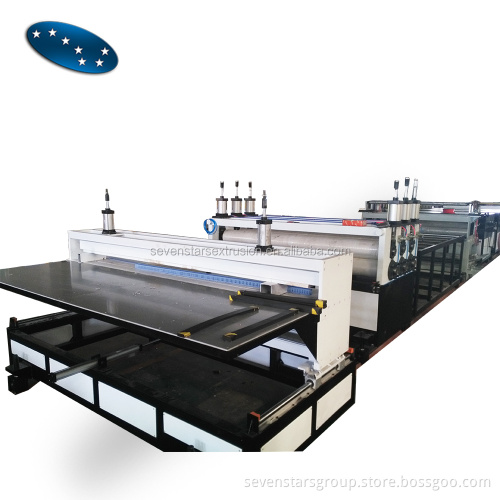

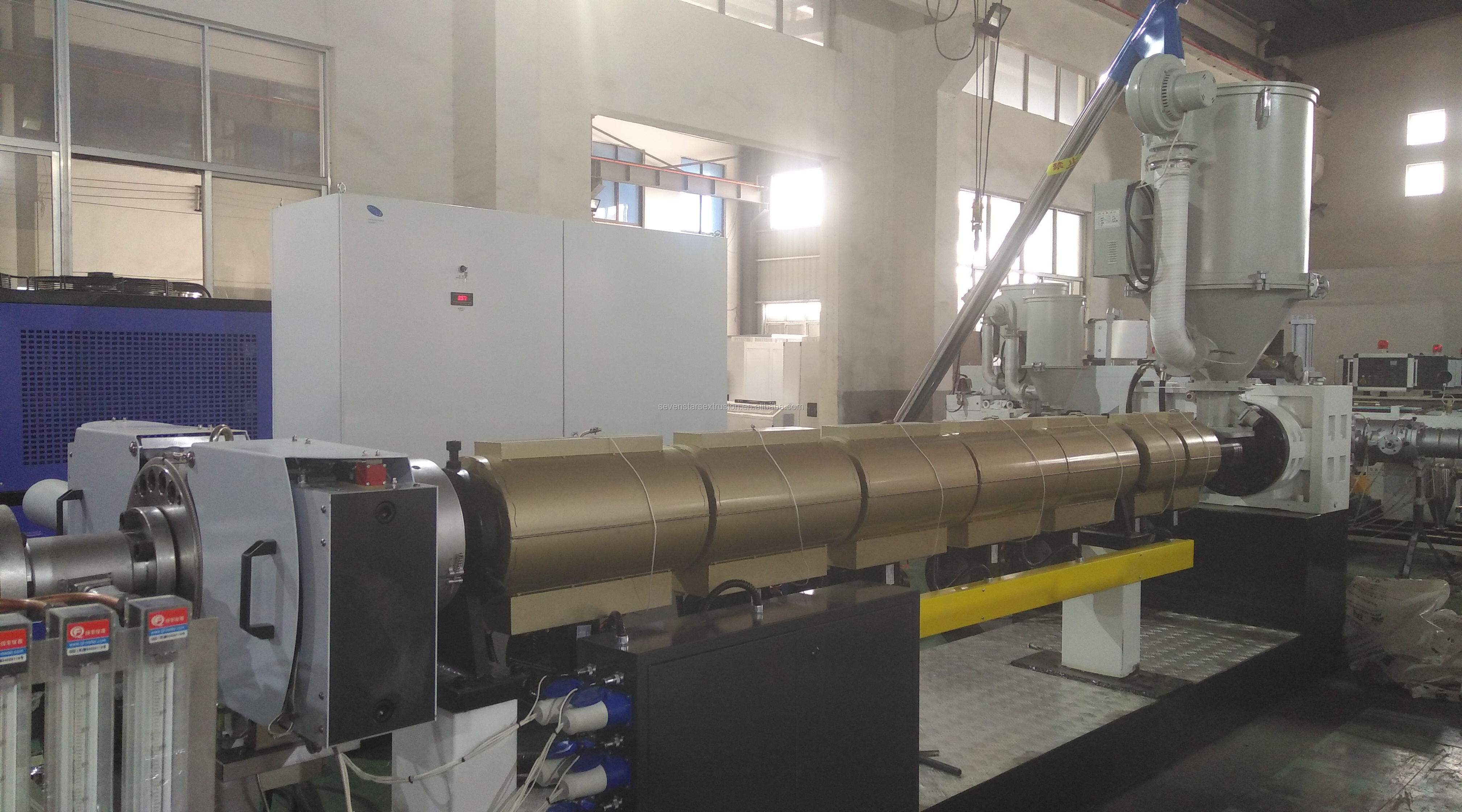

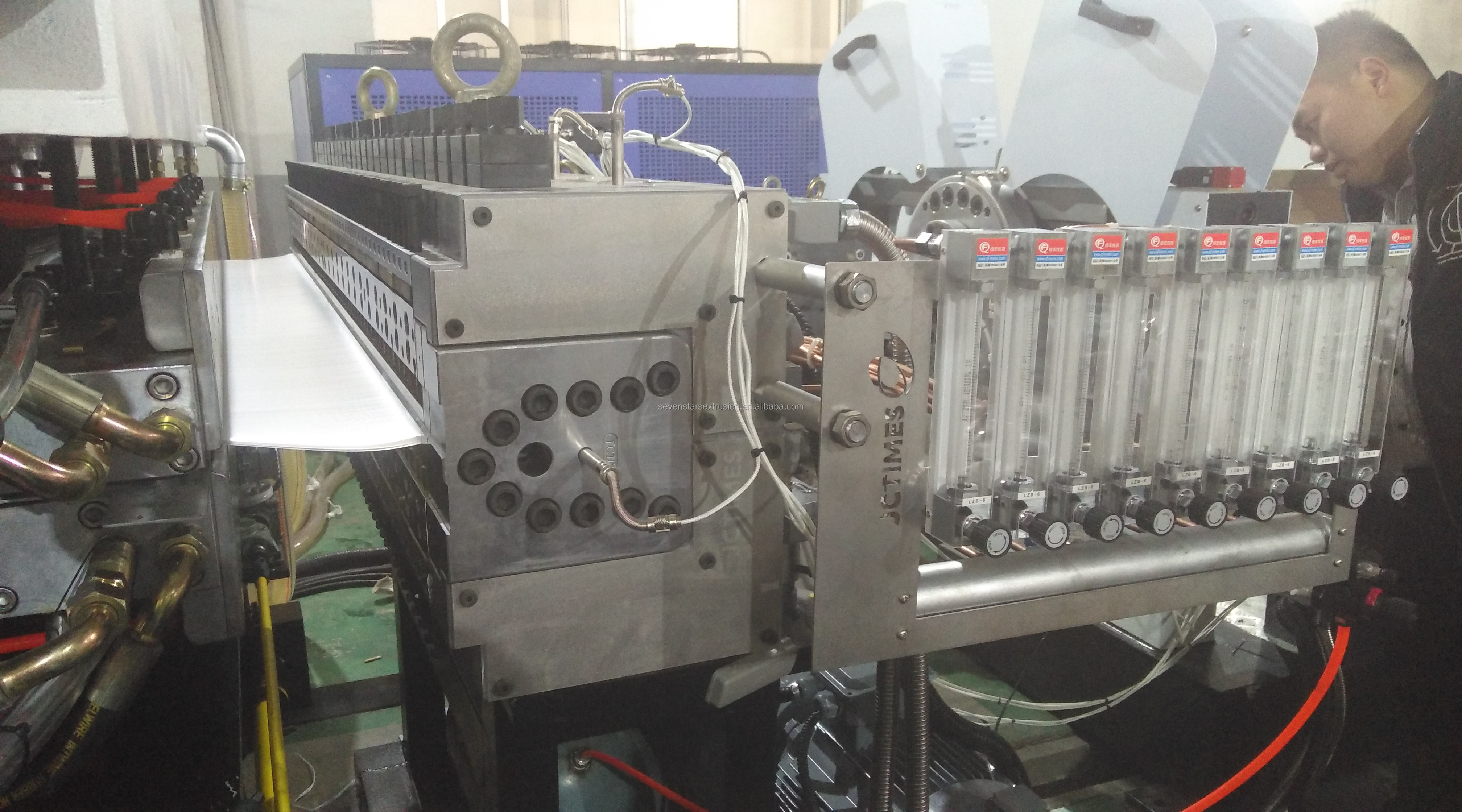

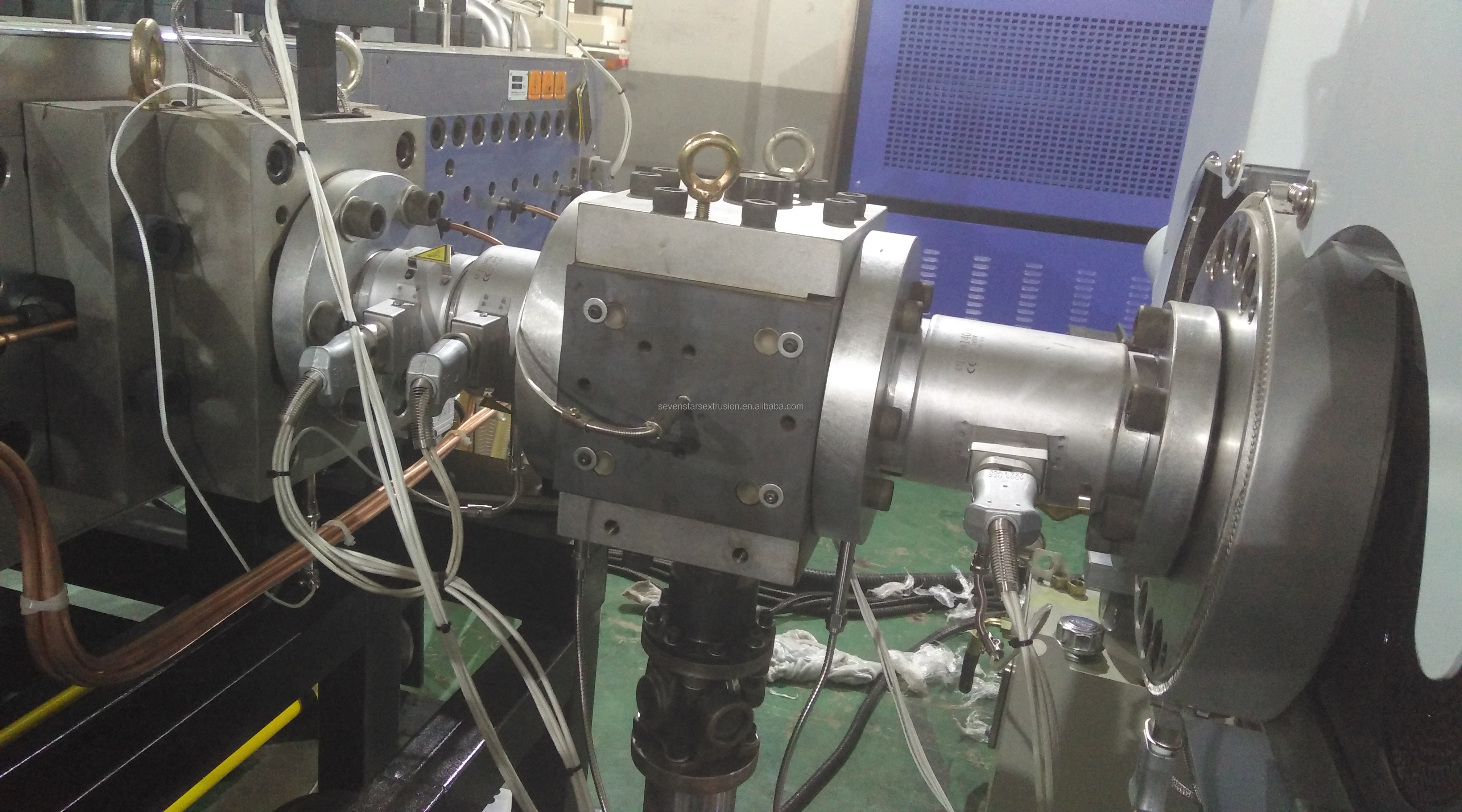

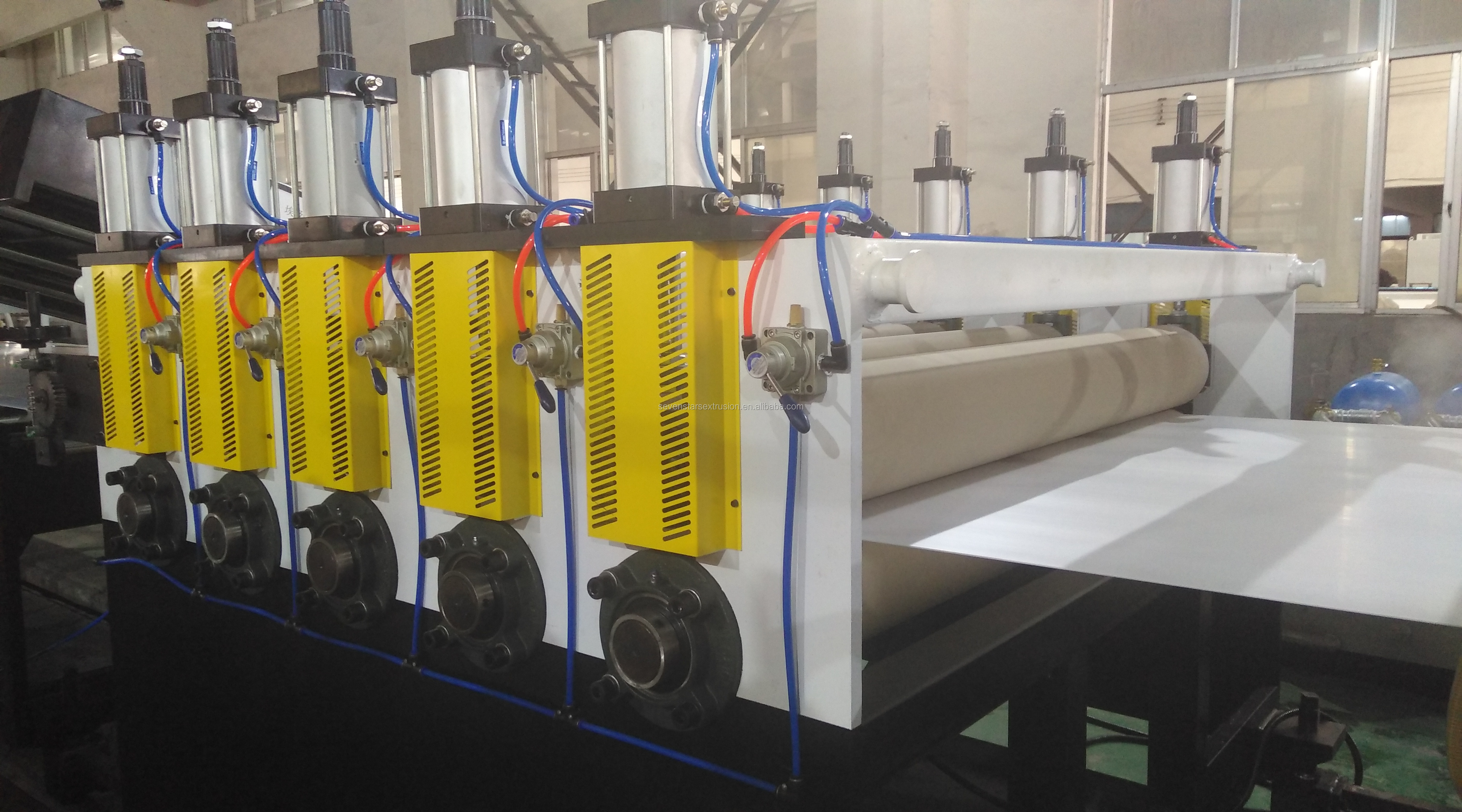

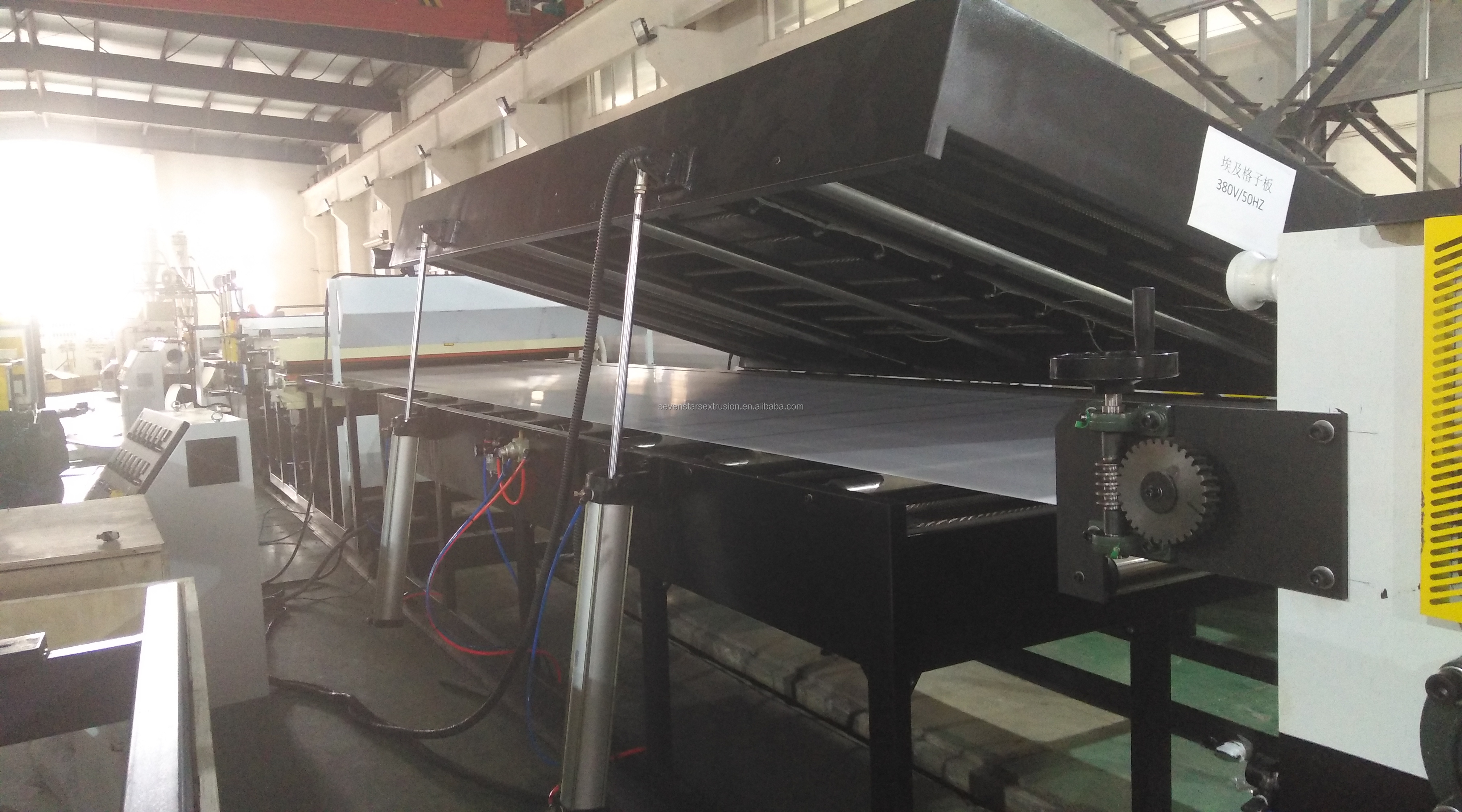

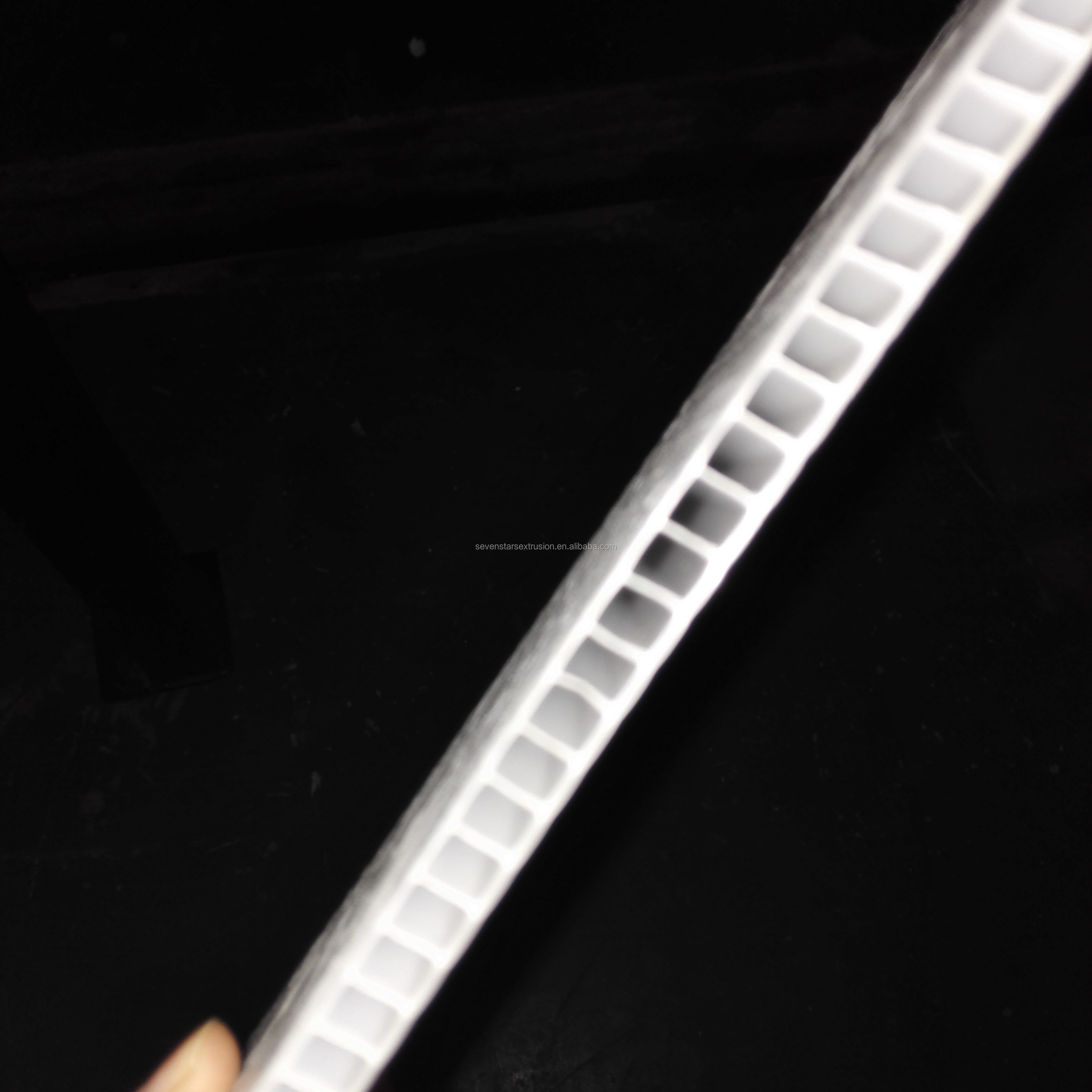

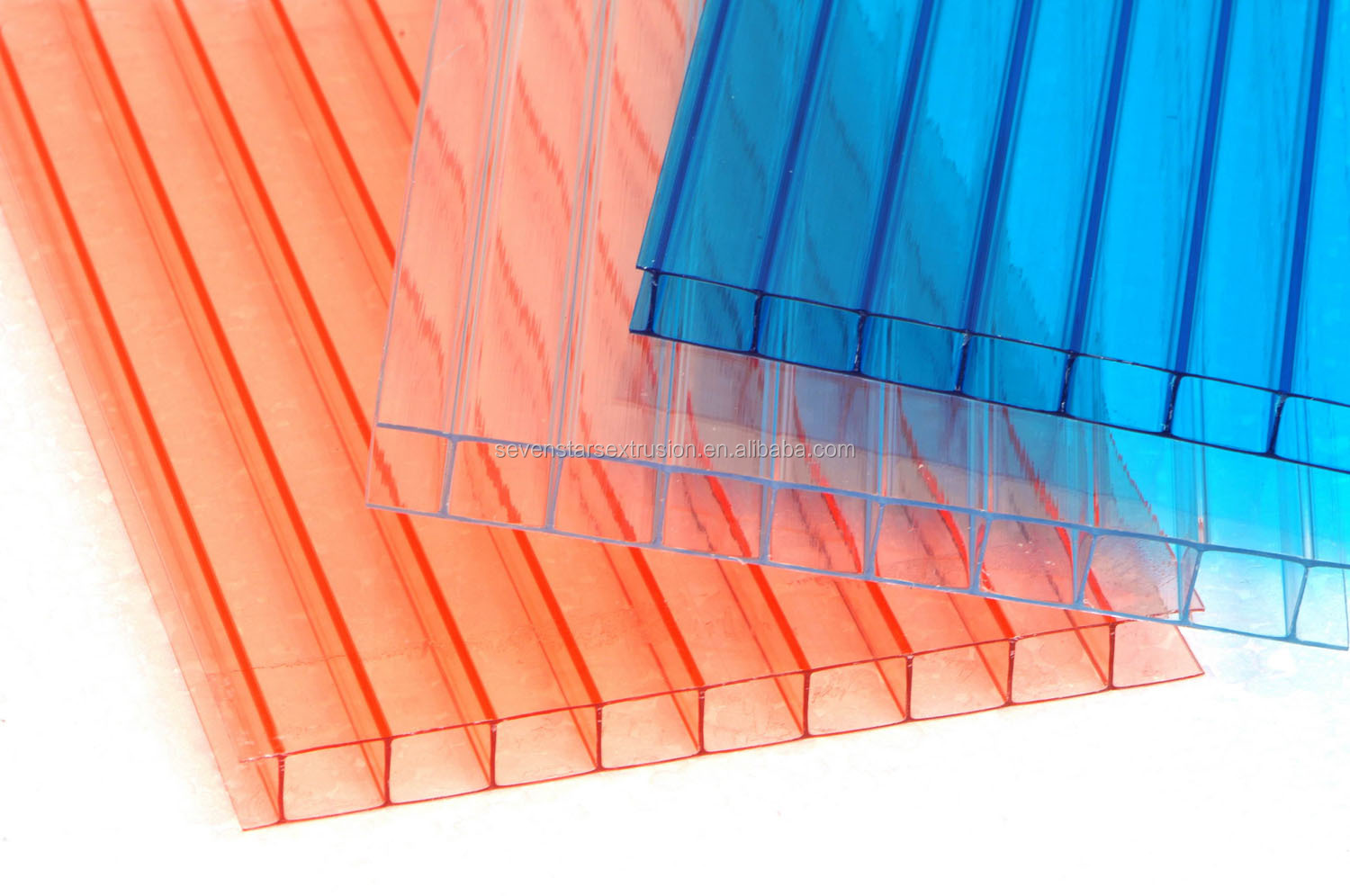

The company's research and development of the leading product is "complete sets of hollow lattice production line and mold", according to the thickness of the product, width, structure, shape, the use of different plastic raw materials have different categories: 1. According to product width: can be divided into 1400mm, 1800mm, 2100mm, 2300mm unit 2. According to product thickness: can be divided into 2-6mm, 6-12mm, 12-18mm unit 3. According to the product structure: Can be divided into double wall, three wall, four wall, 4. According to product shape: can be divided into ordinary I type, S type, V type, X type, meter type 5. According to the use of plastic raw materials products: can be divided into PP, PE, PC

Fluted Plastic Sheet Extrusion Machine,Fluted PP Construction Template Making Line,PP PC Solid Sheet Extruder

PP hollow sheet application

PC hollow sheet application

|

Extruder model

|

Φ100

|

Φ120

|

|

Product width

|

1300/1500mm

|

2100mm

|

|

Product thickness

|

2-12mm

|

2-12mm

|

|

Motor power

|

110kw

|

132kw

|

|

Capacity

|

250-300kg/h

|

400-450kg/h

|

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords