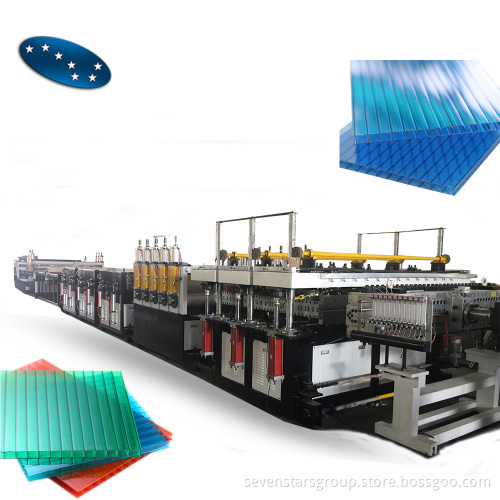

PP Hollow Plastic Formwork Board Sheet Production Line

-

$80000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- shanghai seaport

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,D/P,D/A,T/T,MoneyGram |

| Port: | shanghai seaport |

PP Hollow Plastic Formwork Board Sheet Production Line

Description

The Plastic Formwork Machine,Hollow Plastic Formwork Board Sheet,PE Hollow Grid Board Extruder Production Line. The products is used widely for building, decorating, advertisement laying, road noise isolation ,roofing and packing. PP hollow profile board can instead of carton which have feature like light weight, high strengthen, moisture-proof, antisepsis. Machine part detailed introduction of PC hollow sheet production line/PE hollow sheet production line /PP hollow sheet production line

1. The vacuum calibrator featured with wear-resistance, dirty free and the lifting, falling and leveling for the forming plates is much easier to be controlled.

2. High speed screw, low energy consumption with high rotation speed to match gear pump and stable pressure; output capacity is 25% higher than other brand extrusion lines. because of special design of forming plates.

3. Special designed cooling system for all section of forming plates, and unique designed vacuum system for each section of forming plate.

4. Special designed temperature control oven with cross heat shrink forming, which is much easier to be controlled than other brand extrusion lines.

5. The softness of pull rolls could be customized on request to extend its stretch.

6. The air capacity of hollow sheet and low pressure could be adjusted and controlled slightly, which is easily to be controlled than any other brand extrusion lines.

7. Unique T-Die made by JC Times is specially designed for PP hollow sheet. The thickness of hollow sheet could be from 2mm to 10 mm with twin-wall. The ribbed between walls could be rectangular and diagonal shape.

8. Anti-UV co-extrusion layer could be one sided or two sided, outer surfaces could be sandy or glossy according to configuration requirement.High percentage of recycled flakes could be mixed with the virgin materials.

Overview

The PP hollow sheet making machine is applicable to produce PC,PP,PE hollow profile board. The products is used widely for building, decorating, advertisement laying, road noise isolation and packing. PP hollow profile board can instead of carton which have feature like light weight, high strengthen, moisture-proof, antisepsis.

Features

1. The vacuum calibrator featured with wear-resistance, dirty free and the lifting, falling and leveling for the forming plates is much easier to be controlled.

2. High speed screw, low energy consumption with high rotation speed to match gear pump and stable pressure; output capacity is 25% higher than other brand extrusion lines. because of special design of forming plates.

3. Special designed cooling system for all section of forming plates, and unique designed vacuum system for each section of forming plate.

4. Special designed temperature control oven with cross heat shrink forming, which is much easier to be controlled than other brand extrusion lines.

5. The softness of pull rolls could be customized on request to extend its stretch.

6. The air capacity of hollow sheet and low pressure could be adjusted and controlled slightly, which is easily to be controlled than any other brand extrusion lines.

7. Unique T-Die made by JC Times is specially designed for PP hollow sheet. The thickness of hollow sheet could be from 2mm to 10 mm with twin-wall. The ribbed between walls could be rectangular and diagonal shape.

8. Anti-UV co-extrusion layer could be one sided or two sided, outer surfaces could be sandy or glossy according to configuration requirement.

High percentage of recycled flakes could be mixed with the virgin materials.

|

Extruder model |

Φ100 |

Φ120 |

|

Product width |

1300/1500mm |

2100mm |

|

Product thickness |

2-12mm |

2-12mm |

|

Motor power |

110kw |

132kw |

|

Papacity |

250-300kg/h |

400-450kg/h |

Related Keywords