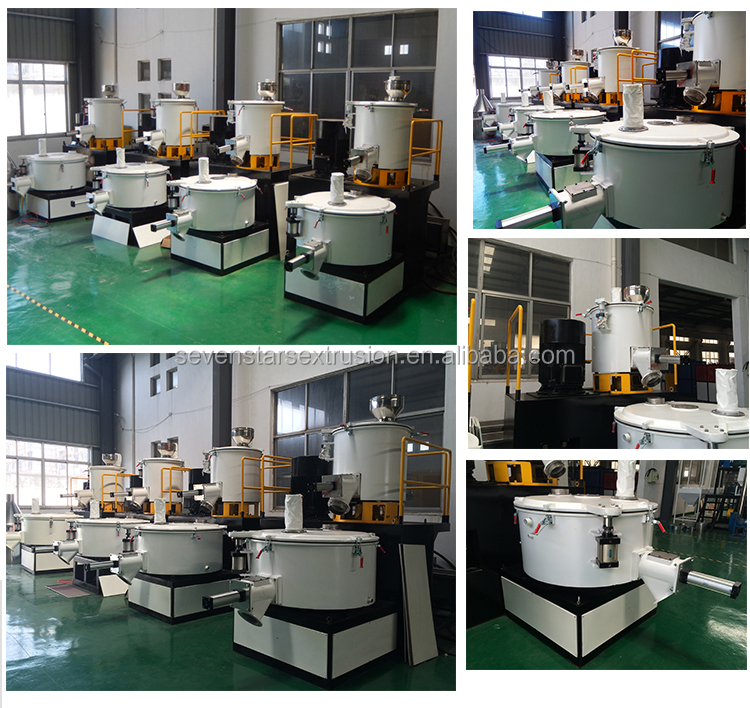

pvc mixer machine plastic powder mixing unit

-

$10000.001-2 Set/Sets

-

$2000.00≥3 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 15 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Transportation: | Ocean,Land |

| Port: | shanghai seaport |

Product Description

Product Description

Product Description

200/500 PVC resin mixer pvc mixer machine plastic powder mixing unit

SRL-Z and SRL-W series mixer unit is applicable for mixing,colouring and drying of various resin such as polyethylene polypropylene polypropylene,chloride etc and in the craft of engineering plastics such as ABS ,polycarbonate etc before forming and processing as well as in the mixing of phenolic resign .The unit combines heat mixing and cool mixing craft together. The materials after heat mixing can be got into cool mixer for cooling automatically,exhausts remaining gases and prevent agglomeration.This unit developed by importing and absorbing advanced foreign technology.By adopting PLC control, it features high automatic level, good mixing result.Heating mixing has such functions as self-friction,and electric heating.The vane has passed the test of dynamic and static equilibrium.The cover adopts double concave-convex seal. Main axis seal adopts special tech of our company,also equipped with pulse dust catching device. Cooling mixer absorbed slowdown tech from ourseas,adopts direct slowdown device, overcomes the deadly weakness causing by use of retarder, that makes it running smoothly even more.This machine has come up to the same kind of product level n the world. That is an ideal equipment producing plates pipes and special-shaped materials etc.

Specification

Model of 200/500 PVC resin mixer pvc mixer machine plastic powder mixing unit

|

Model/specs

|

SRL-Z100/200

|

SRL-Z200/500

|

SRL-Z300/600

|

SRL-Z500/1000

|

SRL-Z800/1600

|

||||

|

Total cubage(L)

|

100/200

|

200/500

|

300/600

|

500/1000

|

800/1600

|

||||

|

Effective cubbage(L)

|

65/130

|

150/320

|

225/380

|

375/650

|

600/1050

|

||||

|

Mixed speed(r/min)

|

650/1300/80

|

475/950/80

|

475/950/80

|

430/860/60

|

370/740/50

|

||||

|

Heating & cooling manner

|

electric heating self-friction/water cooling

|

|

|

|

|

||||

|

Mixed time(min/batch)

|

8-12

|

8-12

|

8-12

|

8-12

|

8-12

|

||||

|

Motor Power(KW)

|

14/22/7.5

|

30/42/11

|

40/55/11

|

47/67/15

|

60/90/22

|

||||

|

Dimension(L×W×H)(mm)

|

1950×1600×1800

|

4580×2240×2470

|

4800×2640×2480

|

4600×3000×4050

|

5170×3200×4480

|

||||

|

Weight(kg)

|

2200

|

3400

|

3600

|

4800

|

6200

|

||||

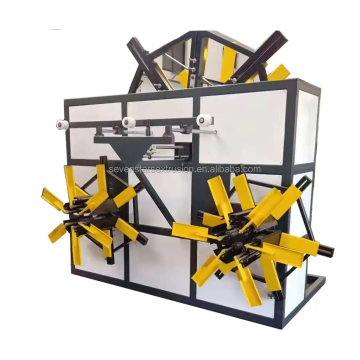

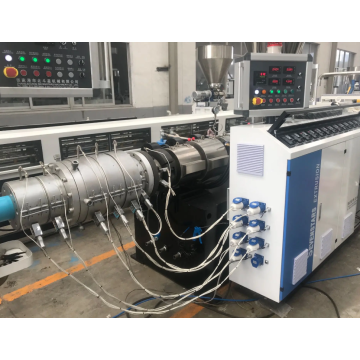

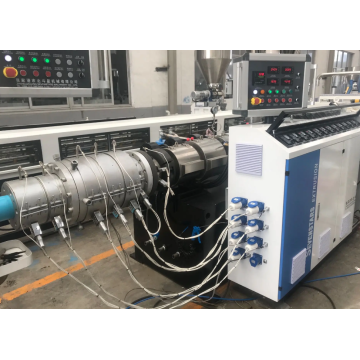

Recommend Products

Contact us

Packing & Delivery

seaworthy panking with strengthen film and bubble film

Company Profile

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords