High Speed Single Wall Corrugated Pipe Production Line

-

$42000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- shanghai seaport

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 300 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,T/T |

| Port: | shanghai seaport |

Product Description

Product Description

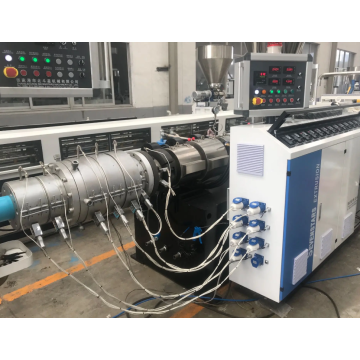

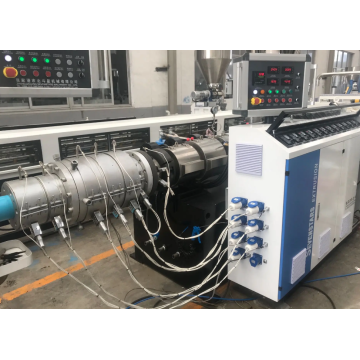

PVC high speed plastic corrugated pipe production line manufacturing machine hoses electricity

PVC PIPE MACHINE LINE

BDX1200(inner diameter Φ50-1200mm) double wall corrugated pipe production line has two single-screw extruder. It has adual-channel structure and nitriding polishing head. The forming machine adopts horizontal structure, chain drive design, advanced water cooling system, vacuum forming system, automatic lubrication system and advanced double-layer on-line expansion function.

The material of the molds is aluminum alloy. The complete production line uses the German Siemens production of professional PLC control system. It has a high degree of automation, reliable operation, easy operation and so on.

The material of the molds is aluminum alloy. The complete production line uses the German Siemens production of professional PLC control system. It has a high degree of automation, reliable operation, easy operation and so on.

Main Advantages

1) Extremely strong resistance to chemical corrosion and erosion.

2) Good flexibility and strong impact resistance

3) Cold resistance and aging resistance. The connection is simple, safe and reliable.

4) Light weight and convenient construction.

5)Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life.

6) Superior drainage performance. It is hygienic and can be recycled and used.

3) Cold resistance and aging resistance. The connection is simple, safe and reliable.

4) Light weight and convenient construction.

5)Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life.

6) Superior drainage performance. It is hygienic and can be recycled and used.

Process Flow

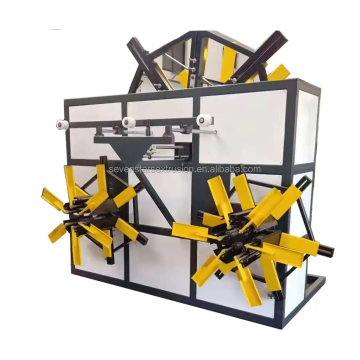

Raw material+additive → Mixing → granulating → Conveying feeding → Single screw extruder 1→ Single screw extruder 2→Co-extrusion mould → Forming machine →Dust free cutter→ Single disc Winder → Finished product inspecting & packing.

Product Paramenters

|

Model

|

Pipe range(mm)

|

Extruder

|

Max.Output(kg/h)

|

Total power(kw)

|

|

BDX80

|

50-60

|

SJ45/30-SJ65/30

|

100-120

|

75

|

|

BDX160

|

63-160

|

SJ55/33-SJ65/33

|

180-220

|

90

|

|

BDX200

|

110-200

|

SJ65/30-SJ65/33

|

250-350

|

110

|

|

BDX800

|

500-800

|

SJ75/33-SJ90/33

|

400-650

|

185

|

Details Images

Related Keywords

Related Keywords