Elevator Destination Floor Group Control System

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- FOB SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 1000pcs/week |

| Supply Ability: | 5000 Set/Sets per Year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | CE, ISO, EN81-20 |

| HS Code: | 8431310001 |

| Transportation: | Ocean |

| Port: | FOB SHANGHAI |

Elevator Destination Floor Group Control System

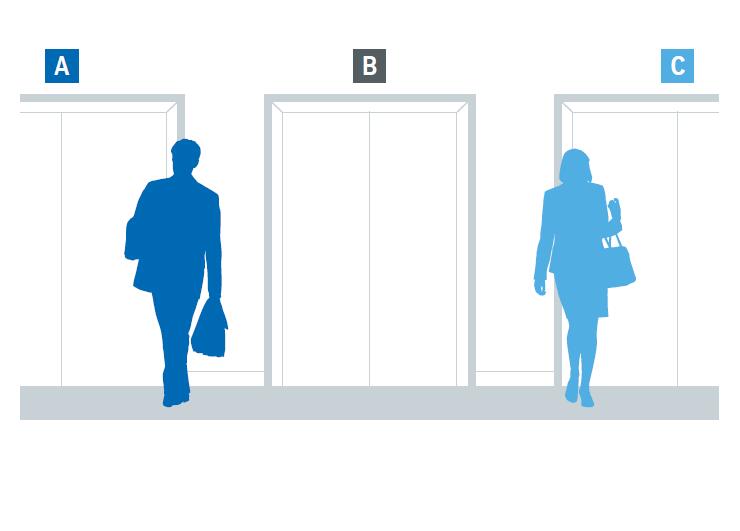

The Destination Control System is an additional system that increases the efficiency of elevator operation and reduces waiting times. Mainly suitable for large buildings with many elevator calls, passengers who need fast, safe and no need to wait for a long time.

The use of the destination control system is premised on building traffic analysis, which calculates average travel time, usage intensity, number of users, etc.

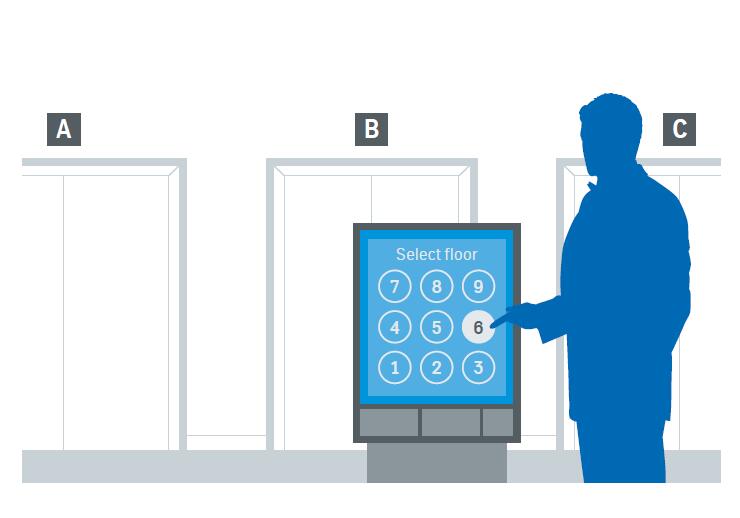

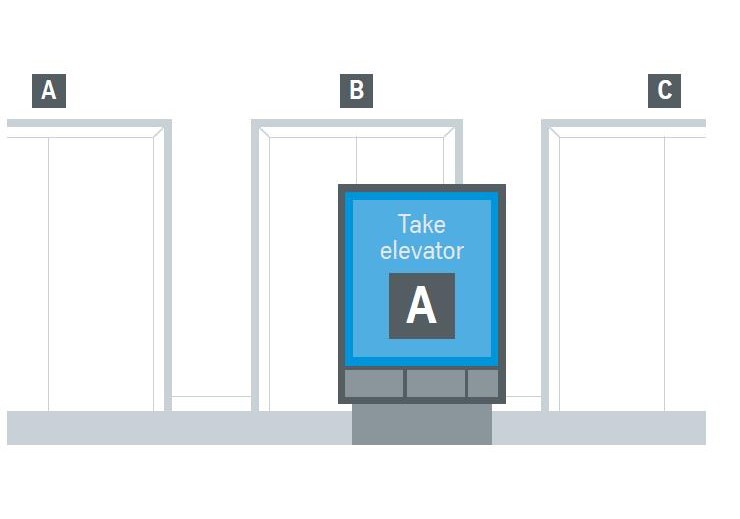

How does this work?

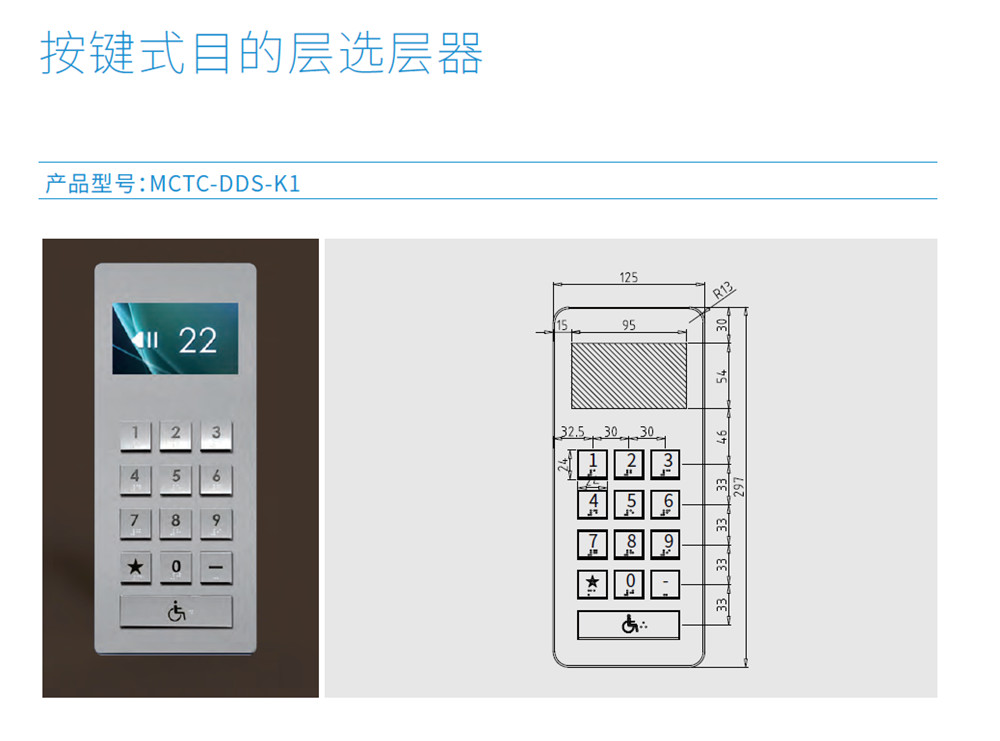

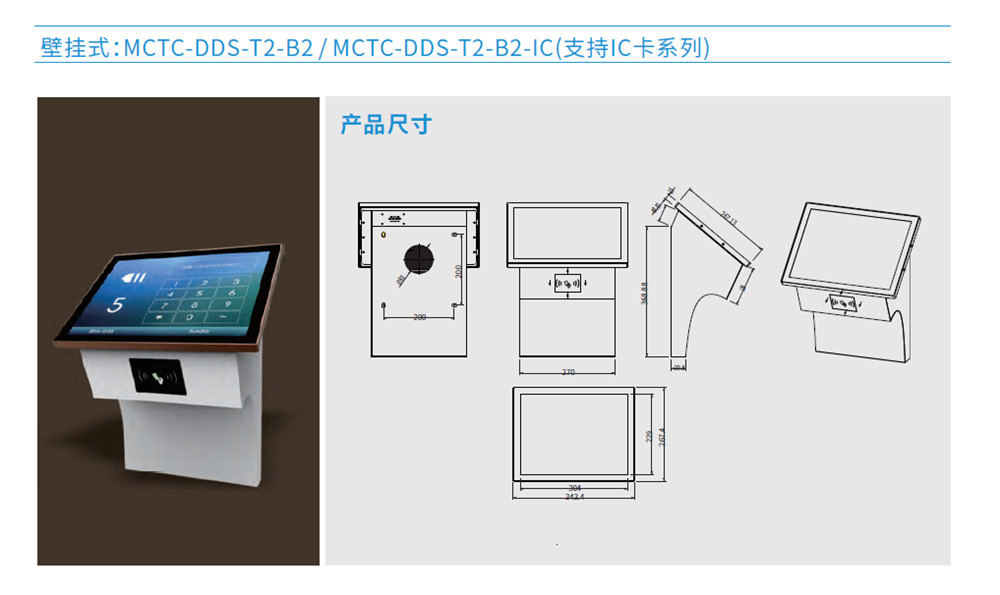

By entering the desired destination, the destination control panel responds, indicating which elevator will run the request. Based on the traffic analysis of the building, there are two options:

Buildings with high traffic density on the ground floor. The touch panel operating system is only installed on the ground floor, while traditional landing operation panels are installed on other floors. The number of touch panels required depends on the number of elevators.

Buildings with high traffic density between multiple floors. A touch screen operating system is installed on each floor. Destination information from the touchscreen operating system is sent to a central processor unit that communicates with each elevator controller to efficiently distribute landing calls.

Advantages

Passenger comfort. The system directs passengers to designated elevators, reducing average wait times and long wait rates, helping to reduce lobby congestion.

Energy saving. Efficient system control reduces unnecessary downtime and reduces building energy consumption.

cut costs. Increased operational efficiency reduces the total number of elevators required.

Flexible configuration. The system adapts to the unique needs of each building. Its efficiency can be further optimized by parameterization of advanced functions.

Efficient and safe. Integrate advanced dispatching technologies such as expert system, fuzzy logic, CAN bus, and neural network to ensure the efficiency and safety of the elevator.

·Elevator Cabin includes

Complete Elevator Cabin, Car Frame, Counterweight Frame and Counterweight Block,Guide Shoes, Rope Attachment etc.

·Door System includes

Mitsubishi, Fermator and Selcom Door Operator and Landing Door, BST Door System, Wittur Door System, Door Panel, Door Spare Parts,Safety Light Curtain/Photocell etc.

·Safety Components includes

Safety Gear, Speed Governor, Rope Brake, Oil Buffer and Rubber Buffer etc.

·Traction System includes

Geared Traction Machine/Gearless Traction Machine, Pulley Sheave,Anti-Vibration Pad,Steel Wire Rope etc.

·Shaft Components includes

Machined /Cold Drawn/ Hollow Guide Rail, Fishplate, Fasteners, Anchor Bolt, Rail Rracket etc.

·Electrical Components inclueds

Integrated and Separated Controlling Cabinet,Yaskawa L1000A Inverter, Elevator Display,Elevator COP&LOP&HOP, Elevator Button, Flat Traveling Cable etc.

Related Keywords