DI1 Elevator Modernization for Passenger Elevator

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Express, Ocean, Land, Air

- Port:

- FOB SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 sets/month |

| Supply Ability: | 100000 Set/Sets per Year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO,CE, TUV |

| HS Code: | 8431310001 |

| Transportation: | Express,Ocean,Land,Air |

| Port: | FOB SHANGHAI |

DI1 Elevator Modernization for Passenger Elevator

Di1 is a model primarily for low rise buildings. It was widely installed in many low rise shopping centers, hotels and other buildings throughout the 2000s. It was originally developed by LG Industrial Systems, LG's elevator division in 1997 and continued to be made after LG merged with Otis in 1999 under the "LG-OTIS" (and later "OTIS-LG") name in South Korea and overseas markets, and since 2006 it is sold under the "Otis" name in South Korea after LG-OTIS became Otis Elevator Korea. By 2013, Di1 was recognized as a low-cost model and was applied occasionally only for remodeling (modernization) in South Korea and since late 2019 it becomes a remodeling model under the M-Kit remodeling package. Along with Ds4, Di1 is a model with a long production period of more than 20 years in South Korea.

Most elevators are built to provide about 20 years of service, as long as service intervals specified and periodic maintenance/inspections by the manufacturer are followed. As the elevator ages and equipment become increasingly difficult to find or replace, along with code changes and deteriorating ride performance, a complete overhaul of the elevator may be suggested to the building owners.

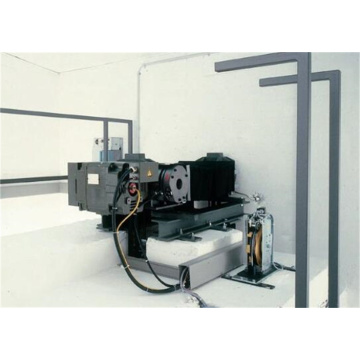

A typical modernization consists of controller equipment, electrical wiring and buttons, position indicators and direction arrows, hoist machines and motors (including door operators), and sometimes door hanger tracks. Rarely are car slings, rails, or other heavy structures changed. The cost of an elevator modernization can range greatly depending on which type of equipment is to be installed.

Modernization can greatly improve operational reliability by replacing mechanical relays and contacts with solid-state electronics. Ride quality can be improved by replacing motor-generator-based drive designs with Variable-Voltage, Variable Frequency (VVVF) drives, providing near-seamless acceleration and deceleration. Passenger safety is also improved by updating systems and equipment to conform to current codes.

Electric Components

·Elevator Cabin includes

Complete Elevator Cabin, Car Frame, Counterweight Frame and Counterweight Block,Guide Shoes, Rope Attachment etc.

·Door System includes

Mitsubishi, Fermator and Selcom Door Operator and Landing Door, BST Door System, Wittur Door System, Door Panel, Door Spare Parts,Safety Light Curtain/Photocell etc.

·Safety Components includes

Safety Gear, Speed Governor, Rope Brake, Oil Buffer and Rubber Buffer etc.

·Traction System includes

Geared Traction Machine/Gearless Traction Machine, Pulley Sheave,Anti-Vibration Pad,Steel Wire Rope etc.

·Shaft Components includes

Machined /Cold Drawn/ Hollow Guide Rail, Fishplate, Fasteners, Anchor Bolt, Rail Rracket etc.

·Electrical Components inclueds

Integrated and Separated Controlling Cabinet,Yaskawa L1000A Inverter, Elevator Display,Elevator COP&LOP&HOP, Elevator Button, Flat Traveling Cable etc.

Related Keywords