All-steel core wire rope

- Min. Order:

- 500 Meter

- Min. Order:

- 500 Meter

- Transportation:

- Ocean

- Port:

- FOB SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000000 Meter/Meters per Yea |

| Supply Ability: | 5000000 Meter/Meters per Year |

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW,Express Delivery |

| Certificate: | CE, ISO |

| HS Code: | 8431310001 |

| Transportation: | Ocean |

| Port: | FOB SHANGHAI |

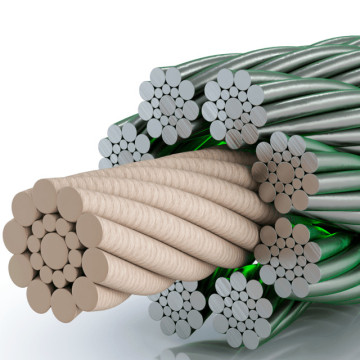

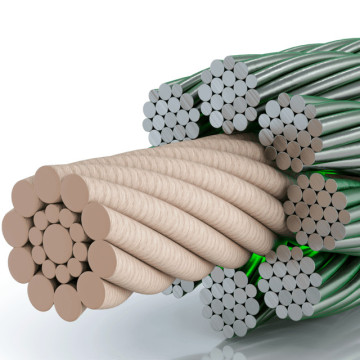

PAWO F10 All-steel core wire rope

Special all-steel core wire rope with 9 outer strands

Our specially developed PAWO F10 is suitable for the most demanding elevator systems. Thanks to its structure of 9 outer strands, the roundness of the wire rope is better, which allows the surface of the rope to engage more precisely with the grooves of the wheel.

More strands result in a more flexible structure, these features combined with very high flexural strength give the rope an extremely long service life. The compact cord design provides extra metal cross section with very low elongation.

Features

Suitable for high-rise elevators

High number of bends

high frequency of use

low wear rate

low elongation

high service life

Construction: 9 outer strands of all-steel-core wire rope, alternately twisted

Technical conditions according to DIN EN 12385, ISO 4344

Number of supporting wires in outer strands:

Diameter to 12 mm = 117 > 12 mm = 144

Nominal strength 1570 MPa, smooth or galvanized steel wire

Steel wire ropes are one of the best choices for elevator applications owing to its two main features: redundancy and detectability.

Redundancy is very important for safety-relevant applications. If one of individual elements is broken, other elements will take on its function and remain in operation taking advantages of interaction between wires.

Detectability means the capacity to determine the end of service life and the degree of bending fatigue of running wires. As fatigue increase, more external wire breaks so that it is possible to estimate by visible inspection before the condition becoming dangerous.

Normally, elevator wire ropes feature parallel strand construction for reducing incidence of abrasion compared with ropes with cross laid construction. Meanwhile, they have a high fatigue bending life and less wear to running sheaves.

Electric Components

·Elevator Cabin includes

Complete Elevator Cabin, Car Frame, Counterweight Frame and Counterweight Block,Guide Shoes, Rope Attachment etc.

·Door System includes

Mitsubishi, Fermator and Selcom Door Operator and Landing Door, BST Door System, Wittur Door System, Door Panel, Door Spare Parts,Safety Light Curtain/Photocell etc.

·Safety Components includes

Safety Gear, Speed Governor, Rope Brake, Oil Buffer and Rubber Buffer etc.

·Traction System includes

Geared Traction Machine/Gearless Traction Machine, Pulley Sheave,Anti-Vibration Pad,Steel Wire Rope etc.

·Shaft Components includes

Machined /Cold Drawn/ Hollow Guide Rail, Fishplate, Fasteners, Anchor Bolt, Rail Rracket etc.

·Electrical Components inclueds

Integrated and Separated Controlling Cabinet,Yaskawa L1000A Inverter, Elevator Display,Elevator COP&LOP&HOP, Elevator Button, Flat Traveling Cable etc.

Related Keywords