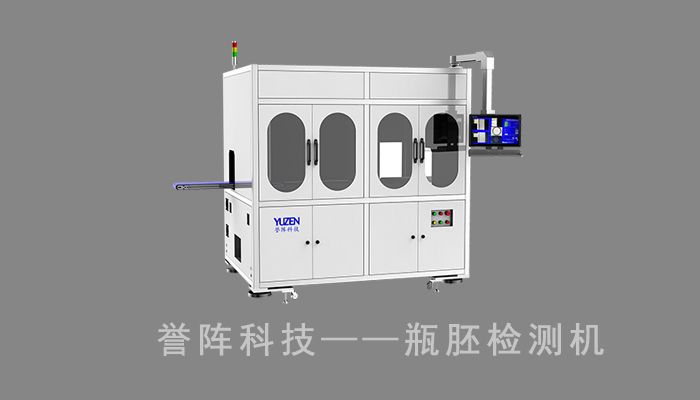

Preform appearance inspection machine

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

Preform Appearance Inspection Machine

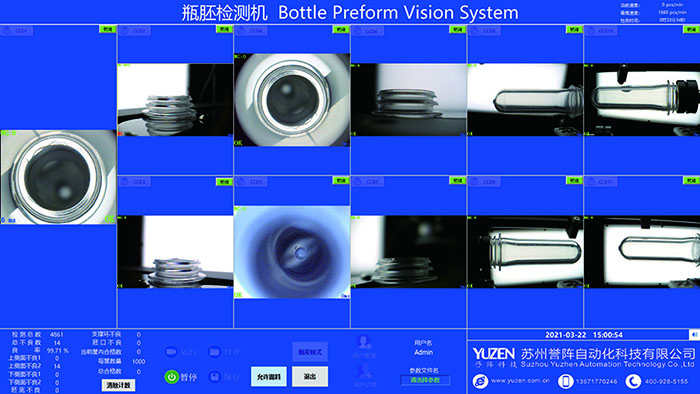

Preform inspection machine is a preform appearance inspection equipment based on artificial intelligence, machine vision and other technologies. Machine Vision System has more and more widespread applications in all walks of life. At the front end of injection molding enterprises, the preform inspection machine or Automated Visual Inspection effect is more pronounced.

Preform appearance defects are common problems encountered by injection molding companies, such as black spots and poor glue openings, embryo body bubbles, wire drawing, lack of glue, bottle mouth damage, black spots dirty, etc., which directly or indirectly cause the final product Unqualified, if Preform Inspection System flows out accidentally, it will bring many hidden dangers to the brand impression and cause huge losses to the enterprise. This has also become a problem that the industry needs to solve urgently.

In response to market customer needs and industry pain points, Yuzhen Technology has developed a set of "PET bottle appearance defect online inspection program-preform inspection machine, using machine vision technology, replacing manual inspection with machines, which can be completed under non-contact conditions. Quickly and efficiently automatically select and reject each preform, which is the first pass for the appearance quality of the preform.

The preform inspection machine uses fully automatic visual inspection technology to help large-scale injection molding, beverage, pharmaceutical and other companies realize unmanned operations, improve the quality of downstream injection molding products, and enhance the intelligence level of injection molding equipment products. A high-quality brand image is of great significance.

Related Keywords