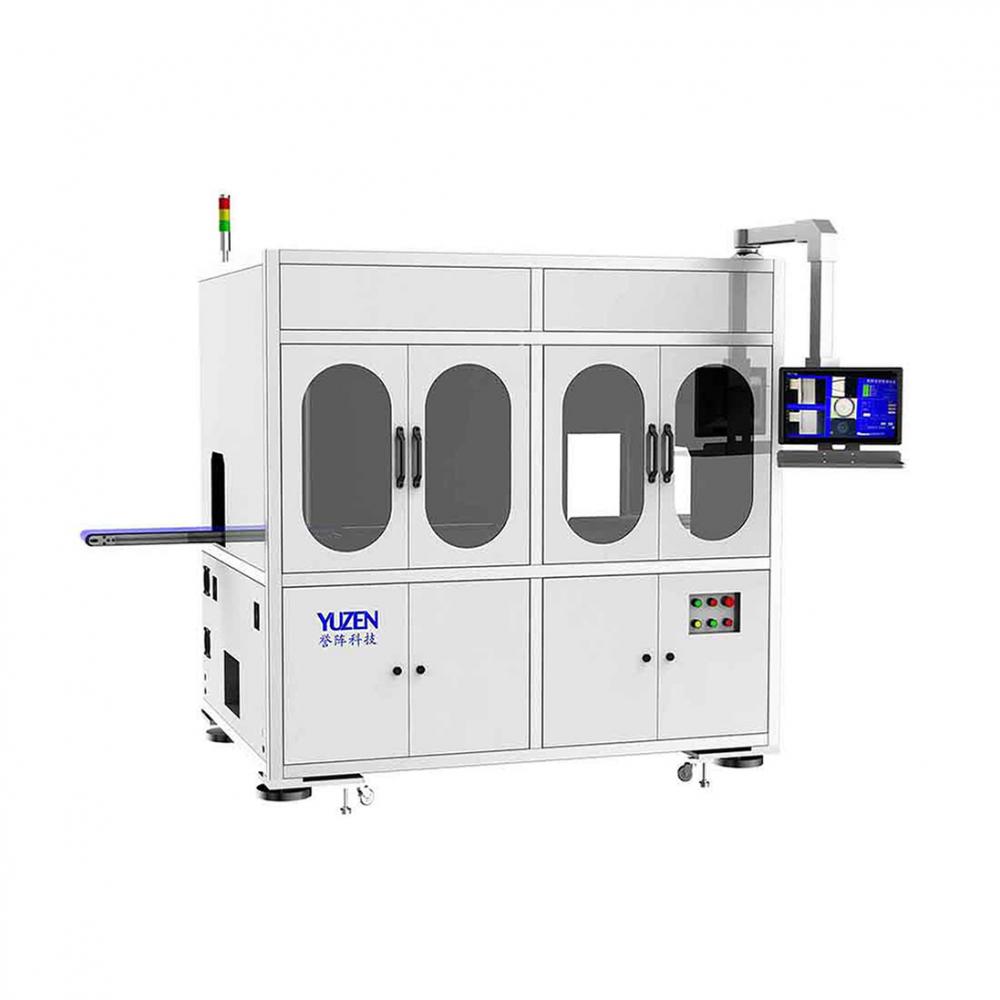

plastic jar vision inspection machine

-

$40000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, By Train

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean,By Train |

| Port: | Shanghai |

Plastic Jar Vision Inspection Machine

For a long time, product quality inspections in the daily chemical, beverage, and plastic packaging industries have relied on manual Plastic Bottle Vision System. This method is not only inefficient, but also easy to cause missed inspections, false inspections, false inspections, and other problems due to objective factors. Moreover, the efficiency is low, and more quality inspection personnel are required, which causes the cost of product appearance inspection link to be too high.

Product features of Visual Inspection Systems:

1. The inspection machine can be connected to a single or multiple blow molding machines according to actual needs, or can be used independently;

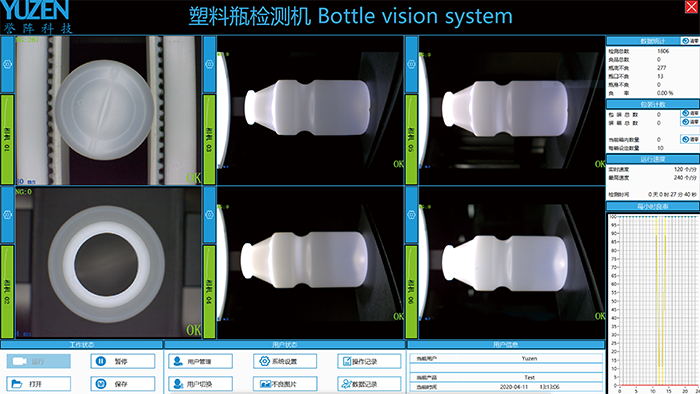

2. The system detects defects such as wire drawing, scratches, bubbles, black spots, lack of material, flash, thickness and other defects and automatically eliminates them online;

3. All-round inspection of bottle mouth, bottle body, bottle bottom, etc.;

4. One machine can correspond to hundreds of products, and the adjustment is simple and quick;

5. Configuration options: the number of cameras is 8-10, the accuracy is 0.1mm-0.5mm, and the speed is 60-150 per minute;

6. Applicable products: PET jars of various specifications.

Product advantages of Vision System For Quality Inspection:

01. Suitable for PET jars of various specifications

02 .All-round inspection of bottle mouth, bottle body and bottle bottom

03 .Detect defects such as flash, lack of material, black spots, dirt, uneven thickness, and deformation

04 .Dust removal, static removal function, 10,000-level purification environment inside the equipment

05. The equipment operation is simple and easy to understand, and equipped with remote debugging function

06. The software complies with GMP certification requirements, audit trails, and intelligent management

07 .Al deep learning algorithm is good at handling various complex inspection items

08 .Special light source design with the system to detect the inside and outside of the product at the same time

09. Equipped with 5-12 cameras according to different needs, and provide three models of low, medium and high speed at the same time

10. Manual adjustment, semi-automatic adjustment, and full-automatic adjustment are available in three types.

Equipment parameters

|

Unit type |

YZ-PT12K-6/10 |

YZ-PT20K-6/10 |

YZ-PT36K-6/10 |

|

Detection function |

Deformation, roundness, flash, black dot, dirt, shor shot and etc |

||

|

Detection speed |

4000 bottles/ hour |

6000 bottles/ hour |

9000 bottles/ hour |

|

Applicable products |

Suitable for PET jars of various specifications |

||

|

Applicable industries |

Manufacturers of various specifications of PET bottles |

||

|

Power |

380V(Optional) /50HZ |

||

Related Keywords