PET bottle visual inspection machine

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

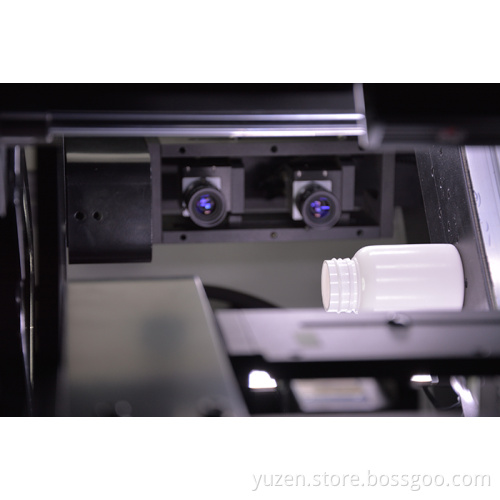

PET bottle visual inspection machine

PET preforms are semi-finished products of beverage packaging bottles, and there are inevitably defects in the production process. Choosing a suitable automatic preform Bottle Inspection System that can replace manual visual inspection has become the consensus of many preform manufacturers.

The preforms currently exist such as support ring damage, flashing, pull-out, lack of glue, air bubbles, bottle mouth damage, oval, impurities, etc., which directly or indirectly cause the final product to be unqualified and bring huge losses to the enterprise. How to remove defective bottles before canning is an important issue faced by PET bottle manufacturers.

Pet Bottle Inspection is a machine vision-based PET preform appearance defect inspection equipment. Compared with the traditional manual light inspection method, this equipment greatly improves the accuracy rate, reduces the inspection time and reduces the production cost. At the same time, it can also collect and feed back the work quality of each process and the type of defects in the production process for analysis and management by process control personnel to improve product quality.

Yuzhen Technology can be equipped with multiple cameras according to the actual needs of users to meet the needs of inspection speed and inspection surface. In addition, the pet preform inspection machine can also be directly connected to the bottle blowing machine, equipped with a reasonable preform machine, and can also be used in the back end of the test. Add side leakage machine, packing machine, packing machine and other back-end auxiliary equipment, so as to realize the complete industrial process from feeding, sorting, testing, screening and rejecting to packing.

The Bottle Vision System can inspect all kinds of preform appearance problems on-line around the clock. It is far superior to manual in terms of speed and accuracy, and is becoming a new intelligent unmanned inspection solution that replaces manual labor.

Related Keywords