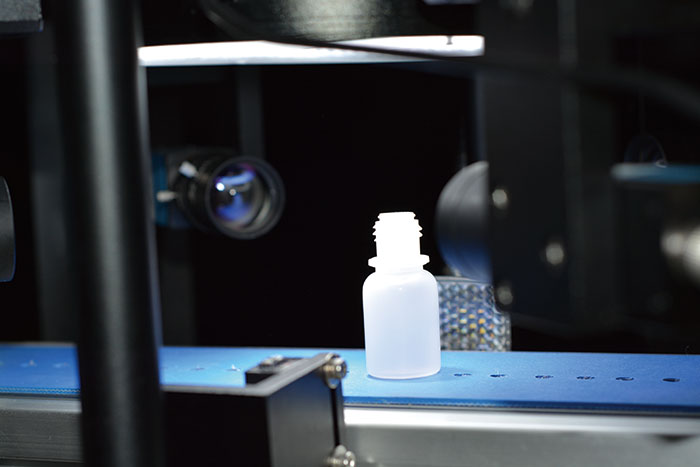

Vial defect visual inspection

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

Vial defect visual inspection machine

The Feature of Medical Bottle Vision System

1. High-speed inspection: Vial defect visual inspection machines can inspect vials at a high speed, which helps in increasing the production rate.

2. Accurate detection: These machines can detect even the smallest defects in vials, such as cracks, chips, and scratches, which are not visible to the naked eye.

3. User-friendly interface: The machines come with a user-friendly interface that allows easy operation and monitoring of the inspection process.

4. Customizable settings: The inspection parameters can be customized according to the specific requirements of the production process.

Bottle Inspection Vision System Dimensions

|

Equipment model

|

BP-YP3K-6 | BP-YP7K-6 | BP-YP12K-6 |

| Detection function | Bottle mouth lack of material, flash, deformation; bottle body black spots, dirt; bottle bottom black spots, dirt, etc. | ||

| Detection speed | 3600bottles/hour | 7200bottles/hour | 36000bottles/hour |

| Use of the product | PET bottle, HDPE bottle, glass bottle | ||

| Application industry | Dairy product bottle packaging, pharmaceutical packaging, daily chemical packaging, food and beverage packaging, wine packaging and other industries | ||

| Power supply | 380V | ||

Related Keywords