Vial defect visual inspection machines

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

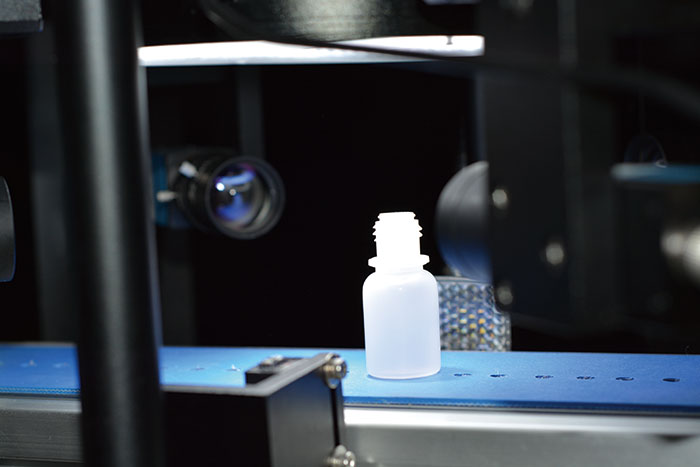

Vial defect visual inspection machine

Medical Bottle Vision System Description

The Vial defect visual inspection machine is used in the pharmaceutical industry to detect any defects in vials that may compromise the quality and safety of the product. The machine uses advanced imaging technology to inspect the vials for defects such as cracks, chips, and other imperfections that may affect the integrity of the product inside. The machine is capable of detecting defects at high speeds and with high accuracy, ensuring that only high-quality vials are used in the production process. This helps to minimize the risk of contamination and ensures that the final product is safe and effective for use by patients.

Bottle Inspection Vision System Dimensions

|

Equipment model

|

BP-YP3K-6 | BP-YP7K-6 | BP-YP12K-6 |

| Detection function | Bottle mouth lack of material, flash, deformation; bottle body black spots, dirt; bottle bottom black spots, dirt, etc. | ||

| Detection speed | 3600bottles/hour | 7200bottles/hour | 36000bottles/hour |

| Use of the product | PET bottle, HDPE bottle, glass bottle | ||

| Application industry | Dairy product bottle packaging, pharmaceutical packaging, daily chemical packaging, food and beverage packaging, wine packaging and other industries | ||

| Power supply | 380V | ||

Related Keywords