Vial defect visual inspection machine

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

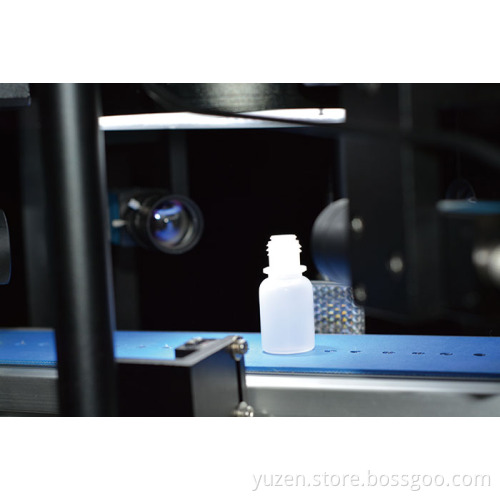

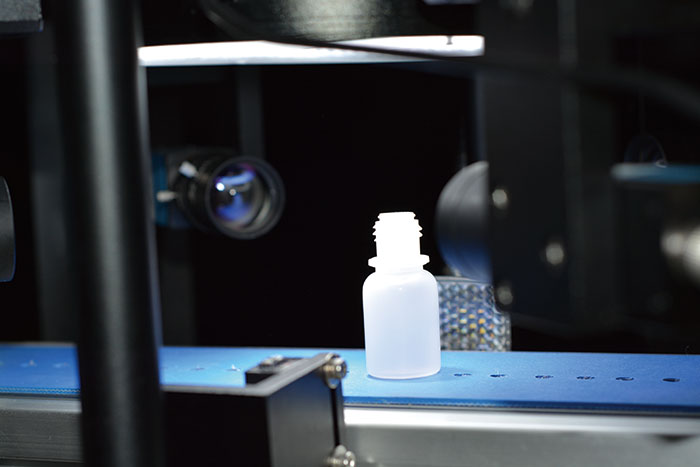

Vial defect visual inspection machine

Appearance defects of medicine bottles without Medical Bottle Vision System are a common production phenomenon in the production process of pharmaceutical companies, which have an immeasurable impact and loss on product quality, and the increase in labor costs has also led many companies to try unmanned visual inspection equipment. Visual inspection machine or Automatic Bottle Inspection is undoubtedly one of the best choices.

The method of the medicine bottle inspection machine to detect defects:

Through the self-developed server software, Yuzhen Technology's visual inspection machine for medicine bottles is controlled with the front end, PLC, and inspection machine to set, limit and control relevant parameters and information, collect image recognition data captured by high-definition cameras, and use professional professional The image processing software amplifies the defects, so as to detect the defect area, size, position coordinates, gray value, etc., and outputs the detection results after analysis and processing, so as to achieve the purpose of rejecting defective products.

Number of cameras and speed:

According to the actual needs of customers, it can be equipped with 5-12 cameras mainly for detection speed, defect types and defective parts, etc. At the same time, it can be equipped with three types of bottle unscramblers: low, medium and high. The high-speed bottle inspection machine can meet multiple equipment. At the same time, the connection requirements can meet 36,000 bottles/hour.

Detection object:

1. Appearance inspection by Camera Vision Inspection System (including size, bottle height, outer diameter of bottle body, outer diameter and height of bottle mouth, etc.

2. Defect detection of bottle body (black spots, lack of material in flash, dirt on folds, impurities, etc.

3. Detection of defective bottle bottom defects (uneven bottle bottom, bottom thorn, etc.

Application areas:

In addition to the detection of poor appearance of medicine bottles, the visual inspection machine can also be used to detect the appearance defects of transparent and non-transparent bottles such as dairy bottles, daily chemical bottles, beverage bottles, and cosmetic bottles. The visual inspection machine adopts robot vision technology to realize the first pass for production under non-contact conditions. Help large enterprises realize unmanned operation in injection workshops, improve the quality of injection.

|

Equipment model

|

BP-YP3K-6 | BP-YP7K-6 | BP-YP12K-6 |

| Detection function | Bottle mouth lack of material, flash, deformation; bottle body black spots, dirt; bottle bottom black spots, dirt, etc. | ||

| Detection speed | 3600bottles/hour | 7200bottles/hour | 36000bottles/hour |

| Use of the product | PET bottle, HDPE bottle, glass bottle | ||

| Application industry | Dairy product bottle packaging, pharmaceutical packaging, daily chemical packaging, food and beverage packaging, wine packaging and other industries | ||

| Power supply | 380V | ||

Related Keywords