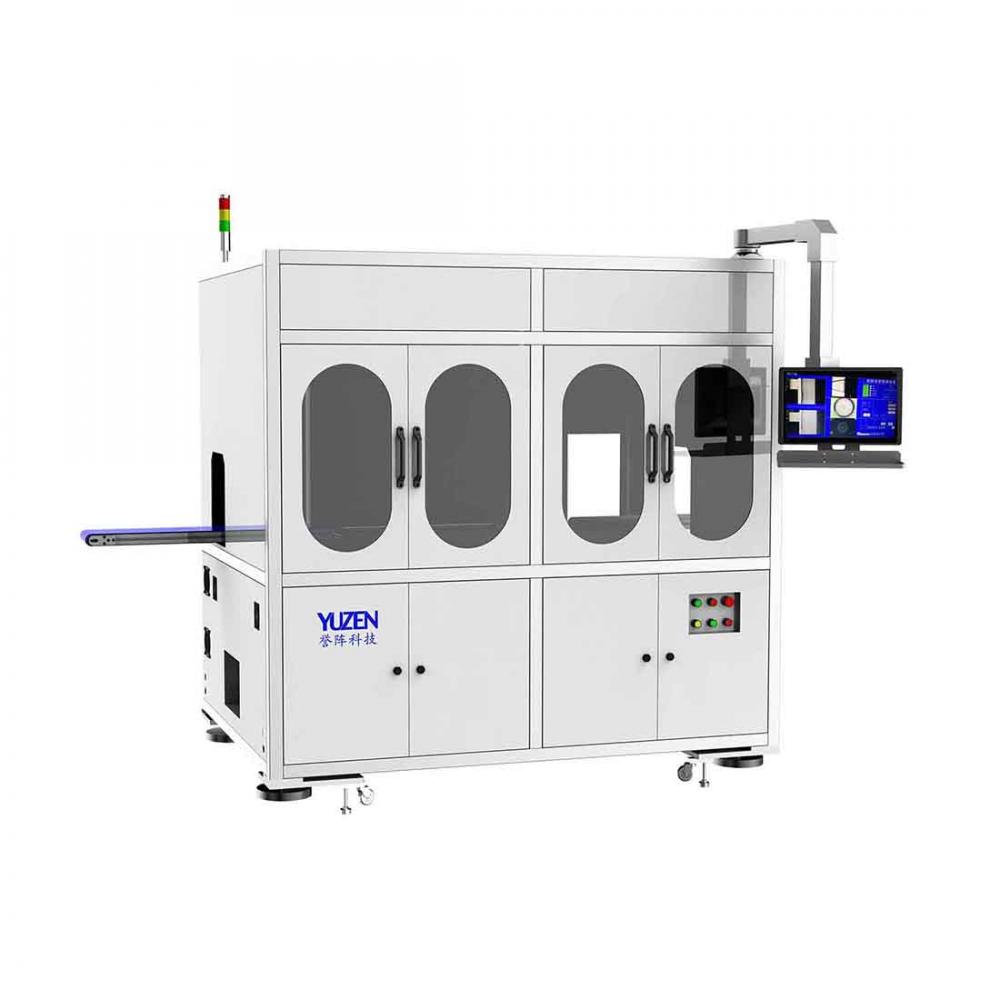

testing and sorting systems for the optical inspection

-

$1.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50sets /month |

| Supply Ability: | 50 sets/month |

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,DDU,CIF,EXW,FAS,FCA,CPT |

| Certificate: | CE,ISO |

| HS Code: | 84749 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Testing and Sorting Systems for The Optical Inspection

Production Description

Custom inspection can be provided too by IML Vision System with each specific product peculiarity. Yuzhen Visual inspection system can detect: different defect, Full Bottle Inspection detect Foreign Particulate Matters from multiple origins. Bottle Inspection includes defection like scratches, glass/plastic deformation, black-spot (burning point on the glass/ plastic surface) or marking defects as well as determining lack of package material, cracks, cap defects, rubber stopper absence, defective crimp, dents, flip off damages.

Our product list

Plastic bottle vision system

Medicine bottle vision system

One machine detects multiple varieties.

Proven packet inspection software;

Compact design saves space for occupying space.

Multifunctional bottle vision system

High precision and more comprehensive defect detection system;

One machine corresponds to multiple varieties.

Intelligent production management;

Multiple optional configurations

Milk bottle vision system

Comprehensive detection of containers;

There is no blind area for multi cameras.

Production statistics management

Multifunctional milk bottle vision system

Connect multiple blowing machines.

High speed and high precision;

Optimize production technology.

Daily chemical bottle vision system

Various bottle type solutions;

Customized according to product characteristics.

Solve complex bottle type’s blind area problem

Wild mouth vision system

Multiple defects in PET bottles were detected simultaneously.

One machine corresponds to hundreds of products.

Connect automatic packing machine to realize unmanned production of blowing bottle

Cap vision system

Medical cap vision system

One machine detects multiple varieties.

Proven packet inspection software;

High speed detection meets production needs.

High speed cap vision system

One machine is compatible with multiple varieties.

The maximum speed can reach 2500 / min.

Various specifications can be selected.

Water beverage bottle cap vision system

Preform vision system

Standard bottle detection machine

All kinds of defects were detected.

There is no blind area for multi cameras.

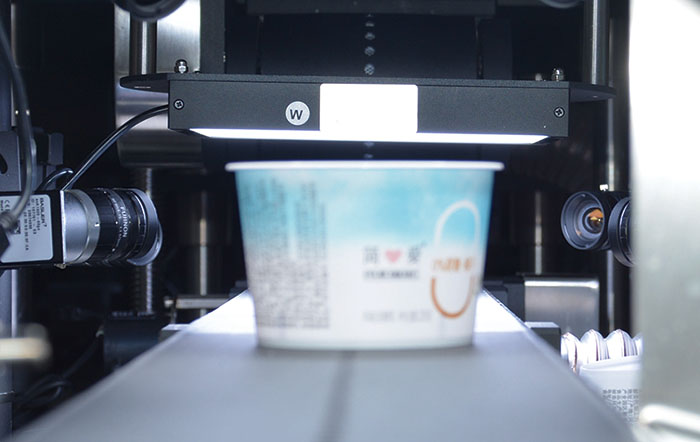

In moud labeling vision system

The labeling effect is simultaneously detected with the appearance of the container.

Automatic stacking cache;

High efficiency and labor saving

Pharmaceutical spray pump vision system

The content of the test is comprehensive.

High standard design in pharmaceutical industry;

Multiple optional configurations

Cap seal vision system

Liquid level vision system

High speed on-line detectionCompact design saves space.

Intelligent production management

Related Keywords