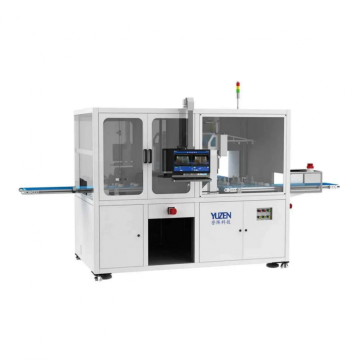

In-mold labeling inspection machine system

- Transportation:

- Ocean, By Train

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean,By Train |

| Port: | Shanghai |

In-mold labeling inspection machine

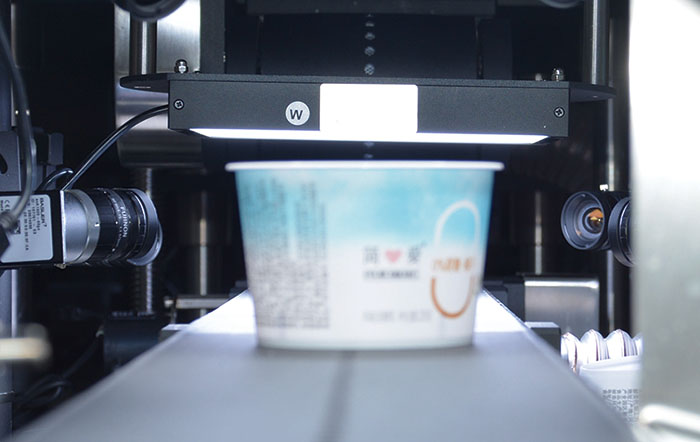

The Vision System Description:

In-mold labeling inspection machines are typically automated, allowing for high-speed inspection and accurate detection of defects. They can be integrated into existing production lines, making them a cost-effective solution for manufacturers. Additionally, these machines can generate detailed reports and data on product quality, allowing for continuous improvement and optimization of the production process.

Advantages of the Visual inspection system:

1. Two installation methods: built-in IML manipulator installation and external independent machine installation;

2. All-round inspection of embryo mouth, embryo body and embryo bottom;

3. After testing, it can be equipped with an automatic stacking manipulator for stacking and packaging;

4. Suitable for all kinds of in-film labeling containers: yogurt cups, bowls, bottles, etc.

5. High-speed and high-precision, instead of manually completing the back-end work of the IML system;

6. The equipment operation is simple and easy to understand, and equipped with remote debugging function;

7. Under special environment, YUZEN special prism can be used to realize multi-angle detection;

8. Equipped with 2-8 cameras according to different needs, one machine is compatible with products of various specifications;

9. There are two ways to choose between manual switching and automatic switching

Introduction of Yuzhen Technology:

Suzhou Yuzhen Technology is a high-tech enterprise integrating R&D, production, sales and service. It focuses on the intelligence and automation of product quality inspection in the packaging industry. The core team has more than 15 years of experience in the machine vision industry and is good at a host Control and process multiple industrial cameras to work at the same time. The software system is equipped with intelligent deep learning algorithms. The use of special optical prisms or multi-camera combinations can achieve 360° omni-directional detection of specific products without blind spots, and intelligently classify the detection results to classify related data Statistics are fed back to the Industry 4.0 system of smart manufacturing in smart factories to provide a basis for production decision-making. At present, the main products include visual inspection machines, stacking boxing machines, automatic packers and other post-packaging automation equipment.

Label Vision System parameters

|

Unit type |

YZ-PT12K-6/10 |

YZ-PT20K-6/10 |

YZ-PT36K-6/10 |

|

Detection function |

Detect the deformation, flashing, black spots, lack of material, gaskets and other defects of bottle caps and eliminate them online |

||

|

Detection speed |

18000 indivual/ hour |

48000indivual/ hour |

60000 indivual/ hour |

|

Applicable products |

Preforms of various specifications |

||

|

Applicable industries |

Suitable for all kinds of in-film labeling containers: yogurt cups, bowls, bottles, etc. |

||

|

Power |

380V(Optional) /50HZ |

||

Related Keywords