In-mould Labeling Vision Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50sets /month |

| Supply Ability: | 50 |

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,DDU,CIF,EXW,FAS,FCA,CPT |

| Certificate: | CE,ISO |

| HS Code: | 84749 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

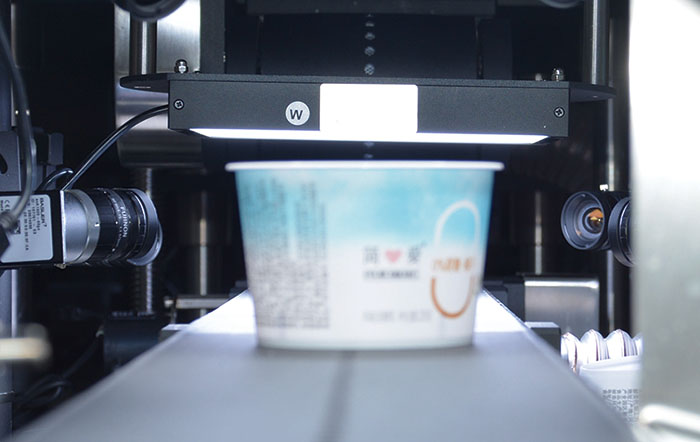

In-mould Labeling Vision Machine

Product advantages:

1. Two installation methods: embedded IML manipulator installation and external independent machine installation

2. Embryo orifice, embryo body and embryo base

3. can be equipped with automatic stacking manipulator for stacking and packaging after detection

4. Suitable for all kinds of internal membrane labeling containers: yogurt cups, bowls, jars, etc

5. High speed and high precision, instead of manual completion of IML system back-end work

6. The device is easy to operate and is equipped with remote debugging function

7. YUZEN prism can be used to realize multi-angle detection in special environment.

8. Equipped with 2-8 cameras according to different needs, one machine is compatible with a variety of specifications

9. Manual switchover and automatic switchover are available

Product Description of In-mould Labeling Vision System:

The Label Inspection machine is connected to the horizontal internal Label Vision System. The machine consists of detection unit and bad product training unit. Sub-material unit stacking whole column unit composition.

High speed, high precision, replace manual IML system to complete the back section of the work.

Configuration and matching: Number of cameras: 1-14, accuracy: 0.1mm-0.3mm, speed: 00-1000 / min.

Applicable products: box cup, bowl, bucket and other in-mold labeling products.

Related Keywords