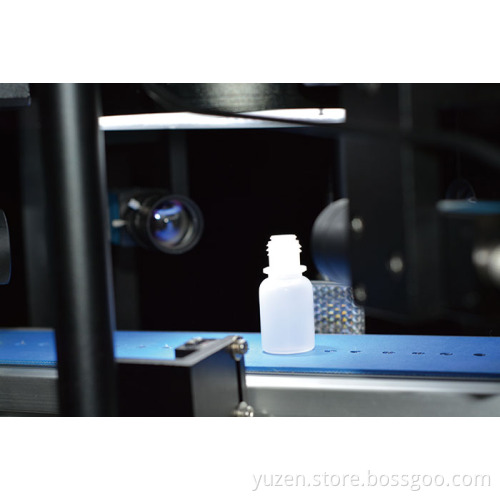

Dropping bottle visual inspection machine

-

$35000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean |

| Port: | Shanghai |

Dropping Bottle Visual Inspection Machine

The Bottle Inspection System can be widely used in the appearance inspection process of pharmaceutical production enterprises. Its high detection efficiency, multi-directional detection range and accuracy have been favored by many pharmaceutical and health care enterprises.

Due to the quality difference of raw materials, the instability of equipment and the lack of mechanical manual level, etc., during the injection molding process, the Bottle Vision System is prone to appearance quality defects, such as flash, lack of material, scratches, black spots and dirt. etc., which seriously affects the quality and safety of pharmaceutical products. Once the defective products flow out, it will cause great economic losses and cause serious adverse effects on the corporate image.

The traditional visual inspection method for the appearance of artificial drop medicine bottles is time-consuming and labor-intensive, and the detection efficiency is extremely low.

Advantages of drop bottle testing machine used in pharmaceutical companies:

1. Wide range of applications, medicinal solid bottles, eye drop bottles, syrup bottles, health care product bottles, etc. can be used;

2. The detection area is wide, and the bottle mouth, bottle body and bottle bottom are inspected in all directions, and there is no omission;

3. Detect defects such as flash, lack of material, black spots, dirt, uneven thickness and deformation;

4. The operation of the equipment is simple and easy to understand, and it is equipped with remote debugging function;

5. The software meets the requirements of GMP certification, audit trail, and intelligent management;

6. Al deep learning algorithm, good at handling all kinds of complex detection projects;

8. Special light source design, cooperate with the system to take pictures inside and outside the product at the same time;

9. Equipped with 5-12 cameras according to different needs, and provide three models of low, medium and high speed;

10. There are three types of manual adjustment, semi-automatic adjustment and automatic adjustment.

The drop bottle testing machine has been widely used in many well-known companies in the pharmaceutical industry, and has received unanimous praise from users. It will also become a new choice for more pharmaceutical companies to realize intelligent and unmanned inspection of product appearance.

Related Keywords