Daily chemical handle bottle inspection machine

-

$40000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, By Train

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean,By Train |

| Port: | Shanghai |

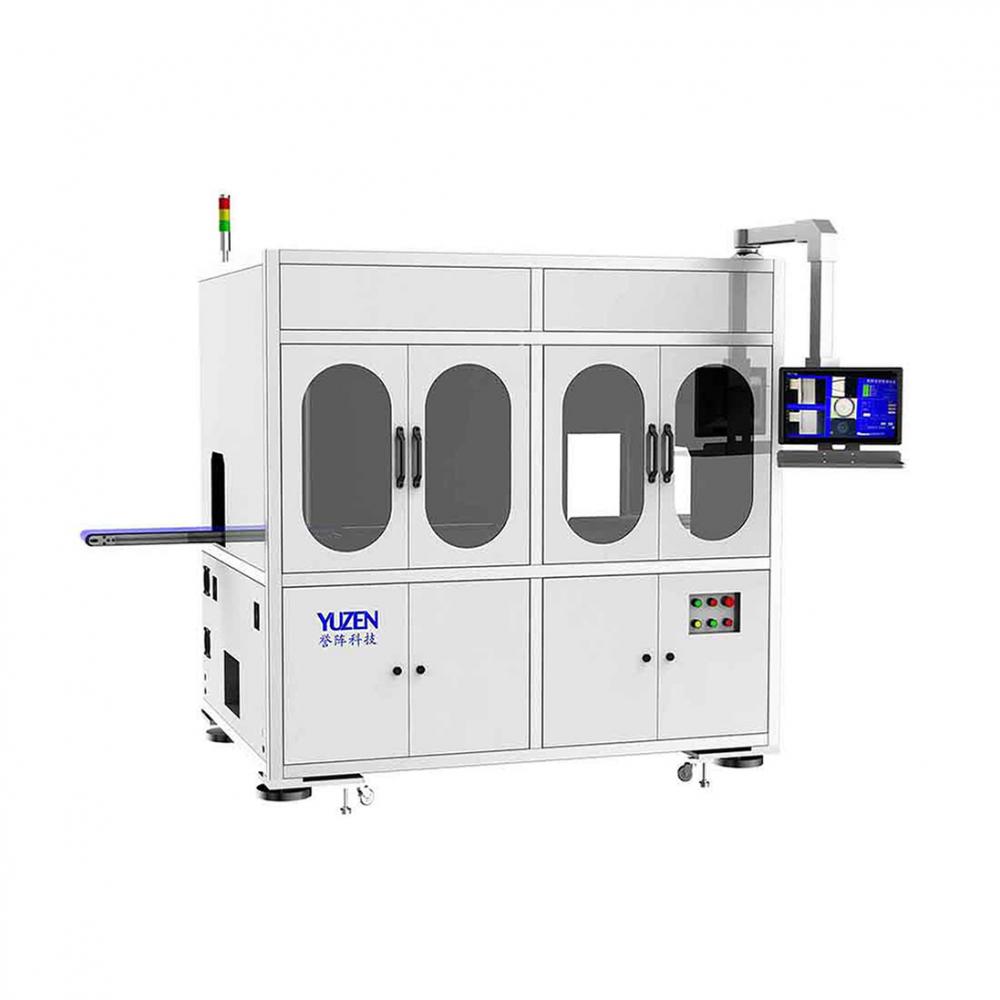

Daily Chemical Handle Bottle Inspection Machine

The visual inspection machine and bottle vision system for cosmetic bottles can not only detect the appearance defects of cosmetic bottles, but also can be widely used in the inspection of transparent or non-transparent bottles such as dairy bottles, daily chemical bottles, and beverage bottles. Main inspection contents: Detecting appearance defects such as lack of material in flash, black spots, uneven thickness, deformation, etc. It can be connected with back-end auxiliary machines such as leak detectors, balers, and case packers, and is equipped with high-speed bottle inspection machines. It can meet the simultaneous connection requirements of multiple devices, and the maximum detection speed can reach 36,000 bottles/hour. It is equipped with special light source design and secondary photography products, which can realize comprehensive inspection of the inside and outside.

Product features of daily chemical handle bottle inspection machine:

1. The inspection machine or Plastic Bottle Inspection System can be connected to a single or multiple blow molding machines according to actual needs, or can be used independently;

2. The Bottle Inspection System detects black spots, dirt, lack of material, excessive glue, deformation, and other defects and automatically removes them online;

3. All-round inspection of bottle mouth, bottle body, bottle bottom, inside and outside of the handle;

4. Design the photo frame according to the characteristics of the bottle type to meet the customer's detection requirements for the specific position of the special-shaped bottle;

5. Configuration options for Bottle Leak Tester: The number of cameras is determined according to the bottle type, the accuracy is 0.1mm-0.5mm, and the speed is 60-300 pcs/min;

6. Applicable products: large handle bottles such as condiment bottles, laundry detergent bottles, motor oil bottles, etc.

Advantages of daily chemical bottle handle inspection machine:

Suitable for large handle bottles such as condiment bottles, laundry detergent bottles, motor oil bottles, etc.;

02 All-round inspection of bottle mouth, bottle body, bottle bottom, inside and outside of the handle;

03 Detect defects such as flash, lack of material, black spots, dirt, uneven thickness, and deformation;

04 Dust removal, static removal function, 10,000-level purification environment inside the equipment;

05 The equipment operation is simple and easy to understand, and equipped with remote debugging function;

06 The software complies with GMP certification requirements, audit trails, and intelligent management;

07 Al deep learning algorithm is good at handling various complex inspection items;

08 Special light source design and system for simultaneous detection of the inside and outside of the secondary camera product;

09 Equipped with 5-12 cameras according to different needs, and provide three models of low, medium and high speed at the same time;

10 Manual adjustment, semi-automatic adjustment, and full-automatic adjustment are available in three types.

Equipment parameters

|

Unit type |

YZ-PT12K-6/10 |

YZ-PT20K-6/10 |

YZ-PT36K-6/10 |

|

Detection function |

Deformation, roundness, flash, black dot, dirt, shor shot and etc |

||

|

Detection speed |

6000 bottles/ hour |

9000 bottles/ hour |

18000 bottles/ hour |

|

Applicable products |

Larger handle bottles such as condiment bottles, laundry detergent bottles, and motor oil bottles. |

||

|

Applicable industries |

Larger handle bottles such as condiment bottles, laundry detergent bottles, and motor oil bottles. |

||

|

Power |

380V(Optional) /50HZ |

||

Related Keywords