Bottle cap visual inspection machine

-

$30000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, By Train

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets /Month |

| Supply Ability: | 50 sets /Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE,ISO 9001 |

| HS Code: | 84749 |

| Transportation: | Ocean,Land,By Train |

| Port: | Shanghai |

Bottle cap visual inspection machine

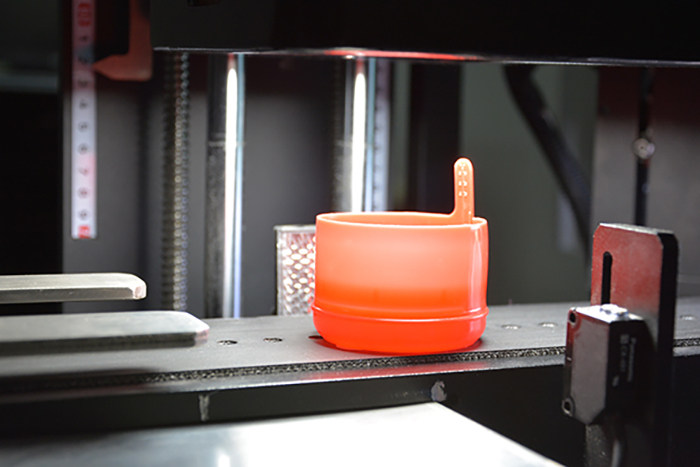

In the plastic packaging industry, product appearance inspection is a very important part. The inspection of bottle caps is more difficult than the bottle body. Choosing appropriate visual appearance inspection equipment or Filled Bottle Inspection Machine will help the packaging industry quickly improve inspection efficiency and complete products. The process of intelligent appearance inspection.

What is my principle of machine vision ainspection equipment?

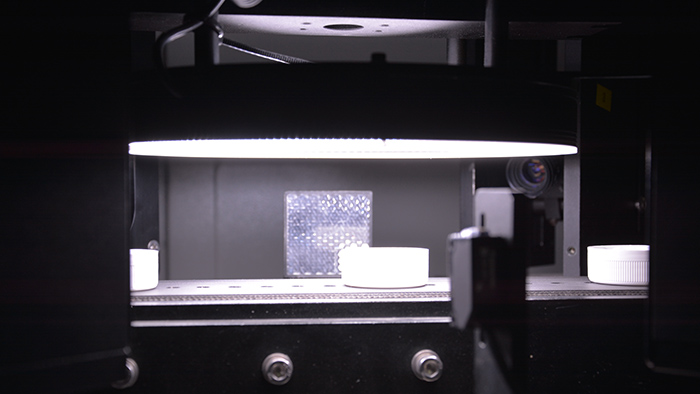

The bottle cap visual inspection machine or Vision Inspection System of Yuzhen Technology uses an industrial camera to obtain the image of the online bottle cap in real time. Through image positioning and analysis, it can quickly determine whether it meets the requirements. Perform detection and output control signals to detect and remove defective bottle caps. The maximum detection speed can reach 3000 pcs/min.

What appearance defects can be detected by Yuzhen Technology bottle cap inspection machine?

Video Measuring Machine can detect the appearance defects such as flashing, deformation, lack of material, black borders, and dirt on the bottle caps of various materials. It can also detect the characters, trademarks, barcodes, etc. on the packaging. With the support of the in-depth algorithm, the more accumulated data, the more accurate the detection It will get higher and higher.

Advantages of Yuzhen Technology's visual inspection machine:

1. It is a perfect substitute for labor; it eliminates the misdetection, slow speed, and high cost of manual detection;

2. Improve efficiency; 360° no dead ends, 24 hours uninterrupted inspection, greatly improve inspection quality and efficiency, and reduce costs as much as possible;

3. Wide detection range; deep AI learning algorithm, good at handling various complex detection items;

4. Data analysis automation and intelligence; production data storage, analysis, and statistics to realize product quality inspection automation;

5. Wide range of use; suitable for all kinds of bottle caps: anti-theft caps, combination caps, butterfly caps, epoxy caps, aluminum plastic caps, etc.

In the era of Industry 4.0, policy support for the automation industry is also increasing. Automated inspection instead of manual inspection has become a trend of the times. Changes in appearance inspection methods are also conducive to reducing enterprise costs and promoting enterprises to achieve new profit growth points.

Equipment parameters

|

Unit type |

YZ-PT12K-6/10 |

YZ-PT20K-6/10 |

YZ-PT36K-6/10 |

|

Detection function |

The system detects the deformation, flashing, black spots, lack of material, gaskets and other defects of bottle caps and eliminates them online |

||

|

Detection speed |

18000 indivual/ hour |

60000indivual/ hour |

120000 indivual/ hour |

|

Applicable products |

Various bottle caps |

||

|

Applicable industries |

Beverages, dairy products, mineral water, wine, daily chemicals and other industries |

||

|

Power |

380V(Optional) /50HZ |

||

Related Keywords