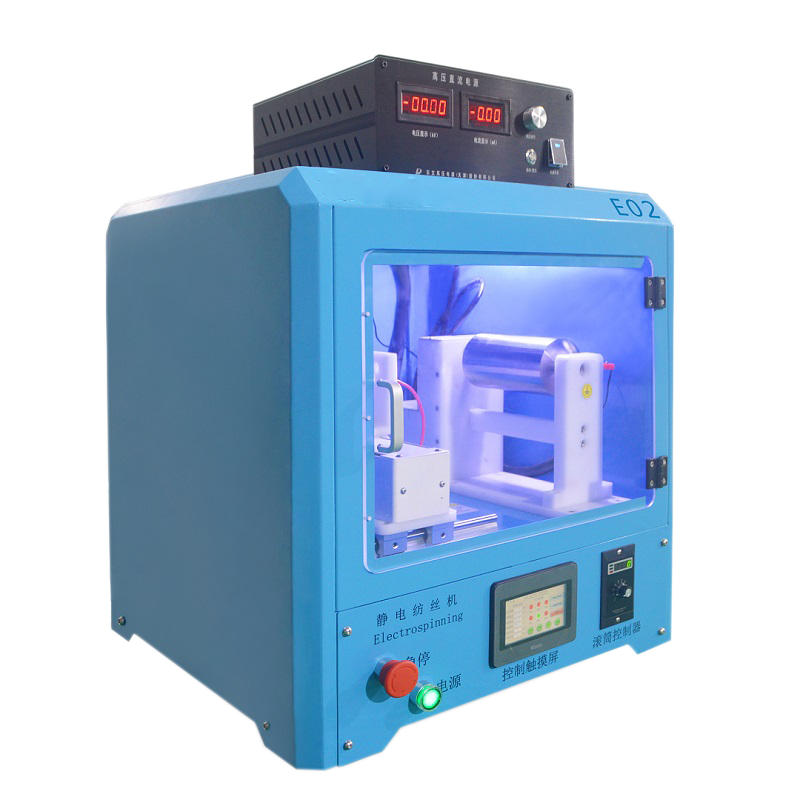

Lab Nanofiber Electrospinning Machine electrostatic spraying

-

$10000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu |

|---|---|

| Productivity: | 10 sets per month |

| Supply Ability: | 10 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001 |

| HS Code: | 8422301090 |

| Transportation: | Ocean |

| Port: | Shanghai |

Product Description

Product Description

PROFESSIONAL ELCTROSPINNING MACHINE E03

Products Description

Product Characteristics:

Desktop style, small size;

Integrated function, lab-scale professional;

Superior performance, CE/FCC certification;

Heating for dehumidification;

4.3-inch numerical screen, simple and clear

integration operating system;

Highly cost-effective, out of box;

Integrated function, lab-scale professional;

Superior performance, CE/FCC certification;

Heating for dehumidification;

4.3-inch numerical screen, simple and clear

integration operating system;

Highly cost-effective, out of box;

Parameters:

High voltage power supply: 0-30 kV, adjustable; Both roller and panel collector;

Nozzle reciprocating motion breadth: 150mm

Dimension: 600*600*800mm

Net weight: 47.46KG

|

Selected Special Configuration

|

|||

|

No.

|

Item

|

Parameters

|

Qty.

|

|

1

|

Three channel syringe pump suite

|

Three different solutions can be extruded simultaneously

|

1 Set

|

|

2

|

Four-needle dual-channel array nozzle head

|

Can realize the similar function of conjugate spinning, spinning efficiency is higher

|

It must be used with the “Three channel syringe pump”,1 Set

|

Electrospinning technology: electrically charged polymer solution or melt is stretched and refined in high-voltage electrostatic field, accompanied by solvent volatilization or melt solidification, and becomes micro-nano-level fiber, which is deposited on the receiving device to form nanofiber film material with a certain accumulation density.

Features of electrospinning materials: High porosity; Small aperture; High specific surface area.

Application: air filtration, water filtration, battery diaphragm, electrode material, tissue engineering, drug sustained release, drug delivery, dressings, artificial skin, heavy metal ion adsorption, gas sensor, waterproof and moisture permeable clothing, catalyst, reinforcement, etc.

Features of electrospinning materials: High porosity; Small aperture; High specific surface area.

Application: air filtration, water filtration, battery diaphragm, electrode material, tissue engineering, drug sustained release, drug delivery, dressings, artificial skin, heavy metal ion adsorption, gas sensor, waterproof and moisture permeable clothing, catalyst, reinforcement, etc.

Polluted waste treatment: heavy metal ion adsorption, acid-base treatment, organic waste gas treatment, organic wastewater treatment, small molecule pollutant adsorption, etc.;

Filtering separation: suspension particles, PM2.5 mask, air filtration, water filter, sifting, oil-water separation, extraction, seawater desalination, etc.;

Biological medicine: air-filtration, drug delivery, dressing, drug extract, tissue engineering scaffold, biological testing, cosmetics, anti-microbial, artificial organ, enzyme immobilization, etc.;

New energy: organic solar cells, li-ion electrode material, sodium-ion battery material, fuel cell, li-ion battery separator, photocatalytic hydrolysis, etc.;

Electronic information: gas sensors, humidity sensors bioinstrumentation, flexible circuit, microfluidic chip, micro/nanodevice, etc.;

Catalysis: organic wastewater and gas catalytic treatment, photocatalysis, chemocatalysis, etc.;

Defense industry: missile insulation, stealth wave-absorbing, light isolated material, electromagnetic shielding, etc.;

Other: food processing, composite enhancing, antiseptic, waterproof and moisture permeable, aerogel, high temperature insulating, keeping warm, etc.

Common Electrospinning Materials

1. Water solubility

PEO polyoxyethylene

PVA polyvinyl alcohol

PVP polyvinylpyrrolidone

2. Water-insoluble

PVDF polyvinylidene fluoride

PAN polyacrylonitrile

PU polyurethane

PA Nylon, polyamide

PS polystyrene

PC polycarbonate

CA cellulose acetate

PMMA polymethyl methacrylate

PET Polyethylene terephthalate

3. Biocompatibility

PCL polycaprolactone

PLA polylactic acid

CS chitosan

SA Sodium Alginate

SF silk fibroin

HA hyaluronic acid

Filtering separation: suspension particles, PM2.5 mask, air filtration, water filter, sifting, oil-water separation, extraction, seawater desalination, etc.;

Biological medicine: air-filtration, drug delivery, dressing, drug extract, tissue engineering scaffold, biological testing, cosmetics, anti-microbial, artificial organ, enzyme immobilization, etc.;

New energy: organic solar cells, li-ion electrode material, sodium-ion battery material, fuel cell, li-ion battery separator, photocatalytic hydrolysis, etc.;

Electronic information: gas sensors, humidity sensors bioinstrumentation, flexible circuit, microfluidic chip, micro/nanodevice, etc.;

Catalysis: organic wastewater and gas catalytic treatment, photocatalysis, chemocatalysis, etc.;

Defense industry: missile insulation, stealth wave-absorbing, light isolated material, electromagnetic shielding, etc.;

Other: food processing, composite enhancing, antiseptic, waterproof and moisture permeable, aerogel, high temperature insulating, keeping warm, etc.

Common Electrospinning Materials

1. Water solubility

PEO polyoxyethylene

PVA polyvinyl alcohol

PVP polyvinylpyrrolidone

2. Water-insoluble

PVDF polyvinylidene fluoride

PAN polyacrylonitrile

PU polyurethane

PA Nylon, polyamide

PS polystyrene

PC polycarbonate

CA cellulose acetate

PMMA polymethyl methacrylate

PET Polyethylene terephthalate

3. Biocompatibility

PCL polycaprolactone

PLA polylactic acid

CS chitosan

SA Sodium Alginate

SF silk fibroin

HA hyaluronic acid

Related Keywords

Related Keywords

You May Also Like

You May Also Like