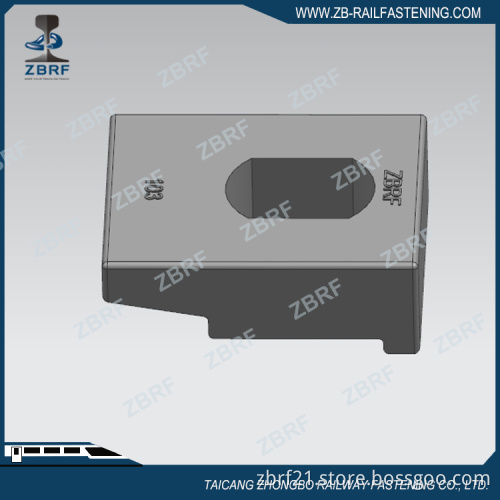

NO.103 crane rail clip

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 200000PCS/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CIP,DDP,DDU,Express Delivery |

| Certificate: | ISO4001/ISO9001/ISO45001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

NO.103 crane rail clip also called rail clip or rail fixing clip, is a device that used to maintain the lateral position of the rail, especially crane rail,mine rail, and H-beam. but allow necessary longitudinal movement. In rail fastening system, the rail clamp secures the rail in position through mechanical lock, in the meantime, accepts the rail longitudinal rail movement through the combined vulcanized-bonded synthetic elastomeric nose. In general, rail clamps are always fastened onto the rail sleepers with anchors bolts. For types, boltable rail clamps and weldable rail clamps are the main varieties.

Technical Parameter of NO.103 crane rail clip

*Application:

1. Crane rail;

2. Mine rail;

3. H-beam

*Material:

Mild steel , middle carbon steel

*Manufacture process:

Hot Forging

Photos of NO.103 crane rail clip

MainType of Rail Clamps

*South/North America

1. Application:

Used for fixing crane rail tracks at port and factories.

2. Size

No.62, No.114, No.103, No.106, No.120

3. Material

Mild steel

|

Chemical composition |

C |

Si |

Mn |

P |

S |

|

≤0.20% |

≤0.35% |

≤1.4% |

≤0.045% |

≤0.045% |

|

|

Mechanical properties |

Tensile strength |

Yield strength |

Hardness (HB) |

|

|

|

370-500MPa |

≥235MPa |

≥120 |

|

|

4. Manufacture method

Hot forging

5. Mark

Manufacture ID, Product ID

6. Coating

Plain, zinc plated, Hot dip galvanized.

7. Supply reference

1) USA

2) Chile

*Africa

1. Application:

Used for fixing crane rail tracks at port and factories.

2. Size

K.R. type A, K.R. type B, K.R. type K

3. Material

Middle carbon steel

|

Chemical composition |

C |

Si |

Mn |

P |

S |

|

0.42-0.5% |

0.17-0.37% |

0.5-0.8% |

≤0.035% |

≤0.035% |

|

|

Mechanical properties |

Tensile strength |

Yield strength |

|

|

|

|

≥690MPa |

≥483MPa |

|

|

|

4. Manufacture method

Hot forging

5. Mark

Manufacture ID, Product ID

6. Coating

Plain, zinc plated, Hot dip galvanized.

*Europe

1. Application:

Used for fixing crane rail tracks at port and factories.

2. Size

M10, M12, M12 LA, M12 LAS

3. Material

Middle carbon steel

|

Chemical composition |

C |

Si |

Mn |

P |

S |

|

0.42-0.5% |

0.17-0.37% |

0.5-0.8% |

≤0.035% |

≤0.035% |

|

|

Mechanical properties |

Tensile strength |

Yield strength |

|

|

|

|

≥600MPa |

≥355MPa |

|

|

|

4. Manufacture method

Hot forging

5. Mark

Manufacture ID, manufacture month and year

6. Coating

Plain, zinc plated, Hot dip galvanized.

7. Supply reference

1) German

Related Keywords