Automatic Label Unrolling Machine

-

$650.001-9 Piece/Pieces

-

$550.00≥10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100pcs/month |

| Supply Ability: | 100pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8479899990 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

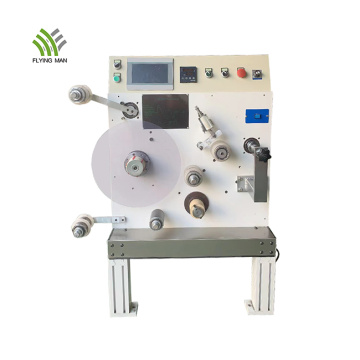

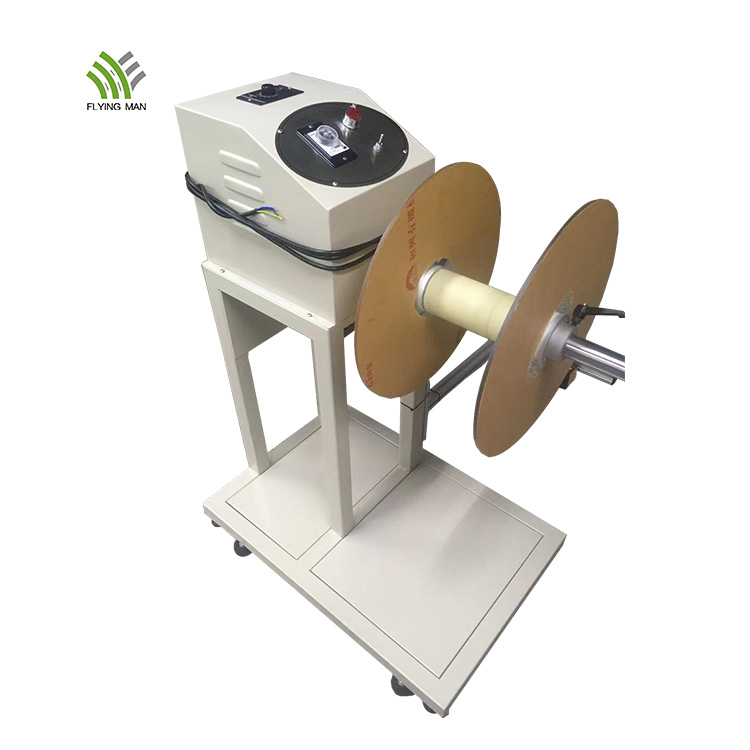

Automatic Label Unrolling Machine

- The unwinding width of this automatic winding machine up to 400mm.

- This auto label unrolling machine is equipped with adjustable speed motors, easy to operate.

- This auto unrolling machine is easy operation with both positive rotation and reverse rotation functions.

- This auto label unwinder is equipped with an electronic sensor head, it can run with the matching machines to control the running speed automatically.

|

SPECIFICATIONS FOR AUTOMATIC UNWINDING MACHINE

|

|

|

|

Model

|

FM-W400

|

|

|

Max. unwinding width Max. unwinding diameter The paper core diameter |

400 mm 850 mm 76 mm (3")

|

|

|

Voltage

|

220 v

|

|

|

Power

|

120 w

|

|

|

Machine Sizes (L*W*H)

|

700 x 500 x 1100 mm

|

|

|

Machine Weight

|

40 kgs

|

|

Training service

After Sales Service

PACKAGE

SHIPPING

Q: Are you a factory or trading company?

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Related Keywords