Keyhole Positioning Automatic Die Cutting Machine

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai port, China, Ningbo port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20 sets/year |

| Supply Ability: | 20 sets/year |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE certification |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai port, China,Ningbo port |

Keyhole Positioning Automatic Die Cutting Machine

The working principle of Microcomputer Medium Die Cutting Machine is to use steel knife, metal mold, steel wire (or template

carved by steel plate), apply a certain pressure through the embodying plate,

the printed matter or cardboard roll into a certain shape. If the entire print in Microcomputer Medium Die Cutting Machine is pressed into a single graphic product, it is called die cutting; If the use

of steel wire in print indentation or leave a curved groove traces, called

indentation; Heating to a certain temperature, hot stamping on the surface of

the printed matter has a three-dimensional effect of the pattern or font, known

as bronzing; If one substrate is used on top of another, it is called

laminating; The rest of Microcomputer Medium Die Cutting Machine is called boating, waste. The above can be referred to as

die cutting technology.

When a product needs to design more than two die cutting forming process, with the Semi Automatic Double Sided Die Cutting Machine will die cutting molding process of the product. Usually the first die cutting in the bearing film (or paper) cut two or three round holes, the second and later die cutting process with the same number, diameter, position of the positioning column precisely set the first die cutting round holes of Semi Automatic Double Sided Die Cutting Machine.

The main engine of Flatbed Panel Precision Backlight Cutting Machine adopts intermittent lubrication with centralized oil supply. There is no obvious oil accumulation inside the machine, and the dirty oil is automatically discharged to the outside of the machine. The main moving parts of Flatbed Panel Precision Backlight Cutting Machine are fully lubricated and do not pollute the environment of the clean room.

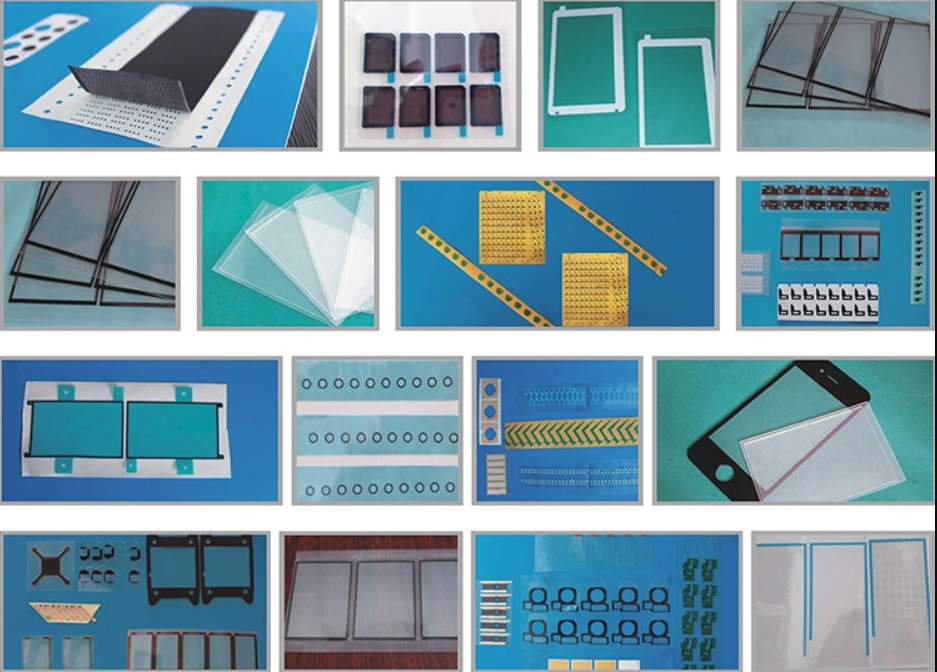

Our Industry Leader Die Cutting Line are widely applied in laminating, slitting and die-cutting for all kind of spare parts in Mobile phone, Laptop, LCD, TV, Medical, Camera, Wearable, E-label, Car and printing etc.

Our precision die cutting machine is suitable to die cut the thin flexible electrically insulating materials such as plastic films, rubber, fibers, and papers. These materials include polyimide films, Mylar PET film, polypropylene, aramid fiber, insulation papers (aka fish paper), PTFE, solid rubber sheets such as silicone, neoprene, and many more etc.

Applications

Our Best Die Cutting Line are widely used in laminating, slitting and die-cutting of various spare parts such as mobile phones, laptops, LCD monitors, TVs, medical, cameras, wearable devices, electronic labels, automobiles and printing.

Related Keywords